...Even if you have an automated bed leveling apparatus, you still need to calibrate your print bed. Allow me to elaborate.

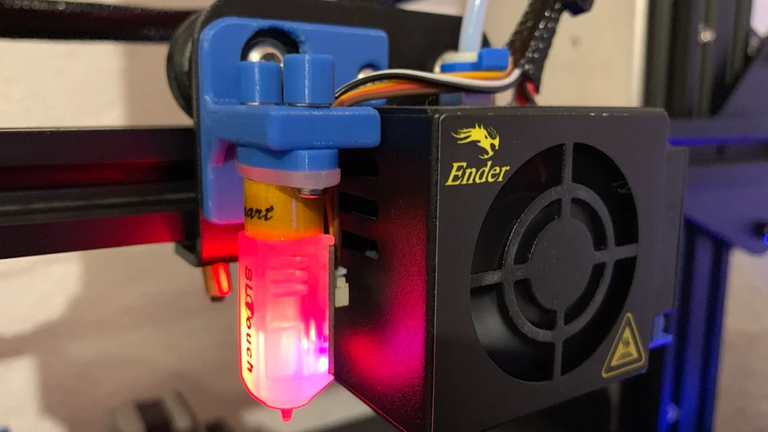

This is a BLTouch. Image has been shamelessly stolen from All3DP, but no matter. It gets the idea across. It's a device for automatically levelling your print bed, so you don't have to futz with it. It's consistently accurate to 0.05mm, every single time. It's great! It definitely helps me with making sure my bed is level every time I go to use my printer. That said, it's been causing me some problems.

For a while now, I have not been able to use half my print bed. The right side of the bed was set super high up compared to the left side. And then, while trying to print a ring box to ship out the Hive logo ring I made, the back-left quadrant started doing the same thing! So I come back to the printer halfway through a 4 hour print and see spaghetti everywhere.

MFW

My back left levelling spring is completely relaxed, too. I'm sitting here, thinking I've really mucked up my printer. And then I have a stroke of genius. What if I were to torque down the bed springs, then manually calibrate it to match up with the nozzle? And at this point, I'm sitting here, thinking:

So I pull all the springs down. I adjust the Z-Offset to compensate a bit, pull the nozzle down to the print bed, and move it across the X- and Y-axes. Sure enough, by raising the corners a wee bit, I'm able to get the print bed level. I try the print. My offset was set too low.

Dial it back in, check one more time, bed is still level, start another print...

And it works! Finally!

And thus, my printer is working much better now. Lucky me! Now I get to print all sorts of awesome things again. Learn from my fail, ladies and gentlemen! That is all.