Introduction

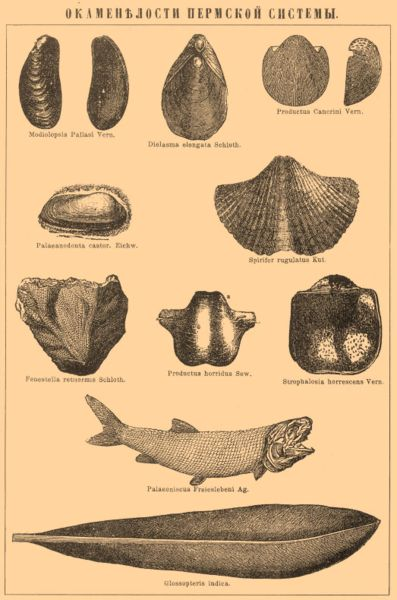

The Permian is a period that belongs to the Paleozoic geological era, geologically this period has a great energetic importance since it is a period where there are large oil reserves worldwide.

However, drilling wells to reach the depth of this geological period is somewhat complicated, which is why technology has had to take giant steps in the advancement of new innovations in order to find an optimized way to drill oil wells in the Permian.

Based on this search for an optimized way to drill oil wells, a proposal arises from the big oil companies Exxon Mobil and Nabors Drilling to drill in the Permian in a fully automated way.

Innovative Permian drilling proposal

Automation in the oil industry and especially in well drilling is the process by which conventional drilling processes are replaced by machines and artificial intelligence to facilitate the work on the drilling rig floor, among which the following stand out:

Screwing and unscrewing the drill pipe each time the well is being drilled deeper.

Control and supervise drilling parameters.

Anyone who has worked in the oil industry knows that the floor of an active drilling rig has long been one of the most dangerous places in the industry. Whether drilling downhole, changing drill bits or pulling drill pipe out of the well, the labor-intensive activities required to drill these deep holes in the ground have always accounted for a significant percentage of the reportable lost-time accidents incurred by companies each year.

Certainly, reader friends, from my own experience I can tell you that the drilling platform floor has the highest danger indexes, since it is where there is the highest probability of having an accident, either because a pipe may hit a worker, or a part of the arm may be amputated when operating with hydraulic wrenches.

Conclusion

With the automation process proposed by Nabors drilling and Exxon Mobil not only improves the drilling process for a geological zone that requires a lot of logistics and drilling time, but we could be taking advantage of the number of personnel working on the drilling rig floor in activities that are also relevant in drilling activities.

The only person who should be trained to work on the rig floor is the driller, who must have the necessary knowledge to manipulate all the automated technological tools that will help to optimize the drilling of wells in the Permian.

References consulted and recommended

ExxonMobil and Nabors Drilling test fully automated drilling rig in the Permian

Greetings @carlos84, the Permian is an interesting epoch, since large animals arose but they were not dinosaurs, but before these. It must require advanced technology to be able to reach these ancient strata and extract the oil.

Hi friend @acont, certainly automation can optimize well drilling to reach the depth of the Permian.

Greetings and thanks for your valuable comment.

Congratulations @carlos84! You have completed the following achievement on the Hive blockchain and have been rewarded with new badge(s) :

Your next target is to reach 210000 upvotes.

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPThanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider supporting our funding proposal, approving our witness (@stem.witness) or delegating to the @stemsocial account (for some ROI).

Please consider using the STEMsocial app app and including @stemsocial as a beneficiary to get a stronger support.

Thank you very much for your support to the StemSocial team. Best regards.

Many thanks to the edu-venezuela team for their support in all my publications.

Best regards.