In today's world of advanced technology, magnetic chip detectors have become essential for the proper functioning and longevity of various devices. These small but powerful tools are widely used in industries such as aviation, automotive, and manufacturing to detect and prevent potential damage caused by metal debris. In this blog post, we will explore the world of magnetic chip detectors, discussing their significance, working principles, applications, and the benefits they offer to different sectors.

What are Magnetic Chip Detectors?

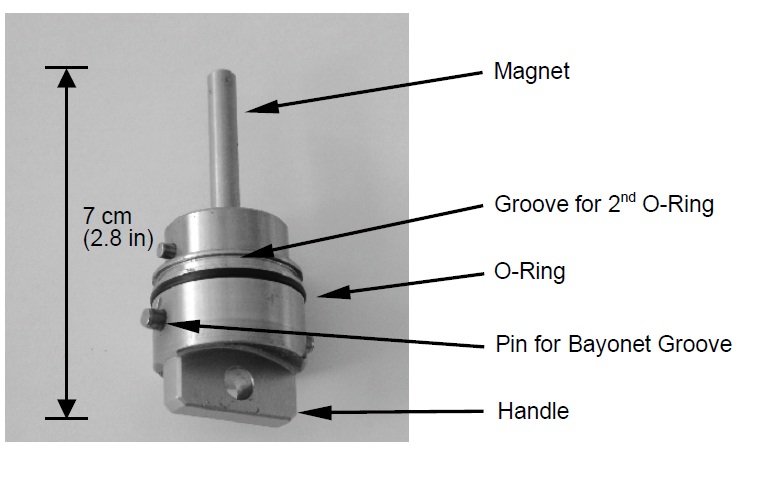

Magnetic chip detectors, also known as ferrous debris monitors, are ingenious electronic devices that utilize magnetic fields to identify metal chips and debris within a system.

These detectors typically consist of a magnet and a sensing element that work together to detect the presence of metallic particles, ranging from microscopic fragments to larger chips. By continuously monitoring for the presence of such debris, magnetic chip detectors can prevent potential damage to critical components and machinery.

How do Magnetic Chip Detectors work?

The working principle of a magnetic chip detector is based on the interaction between a magnetic field and ferrous particles. When metal debris passes through the magnetic field, it becomes magnetized, causing a disturbance in the field.

The sensing element within the detector detects this disturbance and triggers an alert or activates a mechanism to hinder the system's operation. The sensitivity of magnetic chip detectors can be adjusted to accommodate different sizes of debris, ensuring efficient monitoring.

Applications of Magnetic Chip Detectors:

Let's explore some of the key applications of magnetic chip detectors:

Aviation Industry:

In the aviation industry, magnetic chip detectors are critical for ensuring aircraft safety. They are used in engines, hydraulic systems, and gearboxes to identify potential issues caused by wear and tear. By monitoring for metal debris, these detectors contribute to preventing catastrophic failures, minimizing downtime, and ensuring passenger safety.

Automotive Industry:

In the automotive sector, magnetic chip detectors play a crucial role in protecting the performance and longevity of engines and transmissions.

By continuously monitoring lubricating fluids for metal particles, these detectors alert drivers or maintenance personnel to potential problems, such as worn-out components or impending failures. This proactive approach can prevent costly repairs, extend the lifespan of vehicles, and enhance overall reliability.

Manufacturing Industry:

Magnetic chip detectors find extensive use in manufacturing plants, particularly in machinery and equipment that rely on lubrication systems.

By identifying metal debris generated during the manufacturing process, these detectors help maintain the integrity of critical components and prevent damage caused by contaminated lubricants.

The use of magnetic chip detectors ensures smooth operations, reduces downtime, and enhances product quality.

Benefits of Magnetic Chip Detectors:

Let's now discuss some of the key benefits offered by magnetic chip detectors:

Early Warning System:

One of the primary benefits of magnetic chip detectors is their ability to provide early warnings about potential equipment failures. By detecting metal debris at an early stage, these detectors enable maintenance teams to address issues proactively, minimizing the risk of catastrophic breakdowns and reducing costly repairs.

Enhanced Reliability:

The continuous monitoring provided by magnetic chip detectors ensures that machinery and equipment operate under optimal conditions. By preventing the accumulation of metal debris, these detectors enhance the reliability and longevity of critical components, contributing to improved overall system performance.

Cost Savings:

Implementing magnetic chip detectors in various industries leads to significant cost savings. By proactively identifying and addressing problems, companies can avoid expensive repairs, reduce downtime, and extend the lifespan of their equipment.

In a Nutshell:

Magnetic chip detectors are invaluable tools for ensuring the smooth operation and longevity of machinery and equipment across multiple industries. By effectively monitoring for metal debris, these detectors act as an early warning system, enhancing reliability and preventing catastrophic failures.

As technology continues to advance, magnetic chip detectors will undoubtedly play an increasingly vital role, contributing to improved efficiency, reduced costs, and enhanced safety across various sectors.

At Prismecs, we are dedicated to empowering exceptional industrial teams by demonstrating the transformative potential of a single trusted partner for their supply chain and engineered solutions.

As a renowned global supplier, Prismecs possesses extensive resources spanning the globe, enabling us to cater to diverse regions worldwide with an array of high-quality magnetic chip detectors.

Whether it's procuring the necessary components or designing innovative solutions, we take care of every step involved, including ongoing maintenance, ensuring your operations run seamlessly.