My chairmaking project came to a halt when I realized that I no longer owned a mortising chisel. The back slats of a ladderback chair sit in a narrow mortise like this.

I made this chair about 2002, but my workshop burned down in 2009 and I never replaced my set of mortising chisels. However, I did salvage the steel parts of several chisel and an axe. The wooden handles burned off, which isn't a big deal; making a new handle is easy. The problem is that the heat of the fire annealed the metal and made it soft.

Carbon steel has the remarkable ability to take on a wide range of mechanical properties depending on how it is treated. If you heat it up and cool it slowly, the metal is quite soft and easily bent. On the other hand, if you heat the metal and quickly quench it, the properties are completely different. It can be hard, stiff, and even brittle under the right conditions.

In this picture I'm checking a bench chisel with a magnet. The metal is hot enough when a magnet no longer sticks to it, otherwise known as the Curie point.

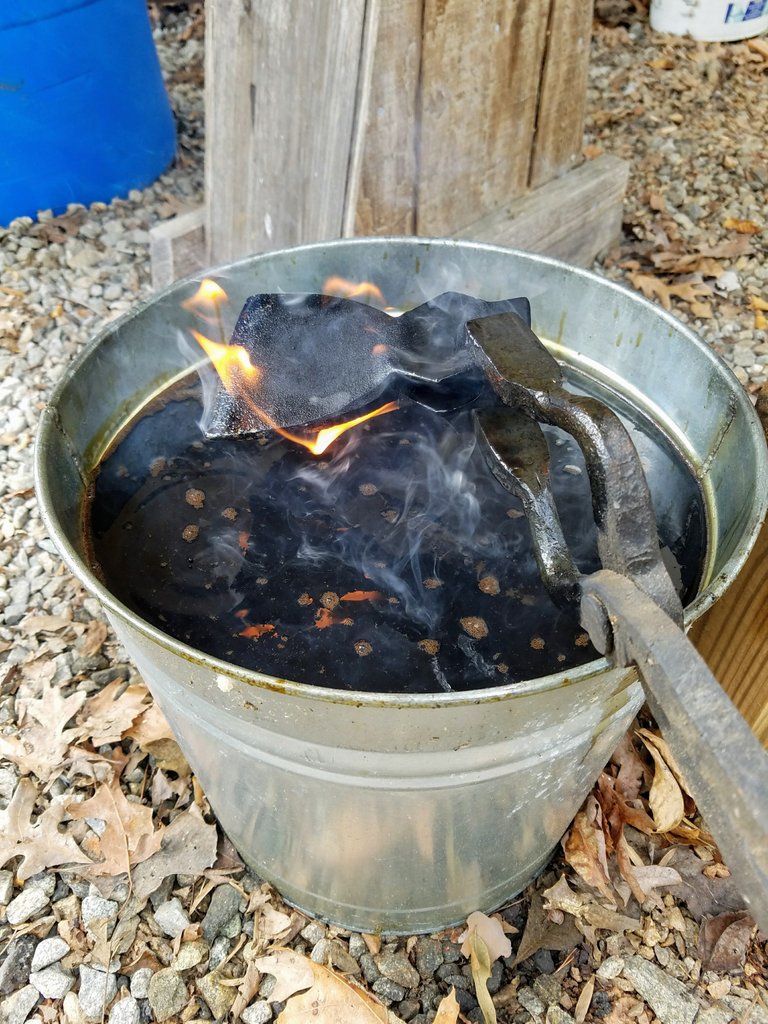

I quenched my tools in oil. Blacksmiths use water, oil, or brine to quench steel, depending on the size of the workpiece and the steel alloy. Oil is the gentlest quench medium and it has the added advantage of catching on fire, which looks awesome.

Everything was going great until I had "too many irons in the fire," and burned a nice socket tang chisel. When the workpiece is buried in the coal you can't see how hot it is getting. If you leave it in too long is burns like a sparkler when you pull it out. Rats.

Even a burned chisel is still salvageable if you have a forge! I cut the burned bit off with an abrasive cutoff saw and heat treated it more carefully the second time.

Some steels, like high speed steel, can be used as soon a they are quenched. Carbon steel, though, is too brittle to hold a cutting edge when it is hardened. I tested one of my mortising chisels just to see if it would work. The metal was so brittle that the cutting edge would break off before you could even finish sharpening it.

I tempered all the tools in one shot using my wife's pottery kiln. The proper tempering temperature is 246C which is lower than the normal firing temperature for pottery, but the temperature controller held it within about 5C.

My mortising chisel held a nice edge after tempering. It took me a long time to regrind and sharpen the cutting edge. I also had to make a new handle, which is pretty easy, but the first two split when I drove them onto the tang. They were dry hickory, which is very hard, but splits easily. This handle is green peach wood. It is easy to work and smells fantastic.

If I had to make a living by making chairs it would be nearly impossible considering how little progress I've made over the past year. Thankfully, that isn't the objective and I enjoyed messing around with my forge.

That's a nice forge pot you have. I've been wanting to either get or build a forge for a while now, but I haven't gotten around to building one yet.

Thanks. It is a brake drum from a dump truck. The air blower is an old shop vac. My sister provided the coal. Coal is often hard to find. She happened to buy a house that doesn't have a coal furnace anymore, but the pit in the basement is still full. It is anthracite (hard coal). Most blacksmiths prefer bituminous coal, but it seemed about the same to me. The bituminous coal crumbles and makes a lot of dust.