Mushroom Farming

The six stages of mushroom cultivating:

Making Mushroom Compost

Finishing the Compost

Spawning

Casing

Pinning

Cropping

These means are depicted in their normally happening arrangement, accentuating the notable highlights inside each progression. Manure gives supplements expected to mushrooms to develop. Two sorts of material are commonly utilized for mushroom fertilizer, the most utilized and most affordable being wheat straw-had relations with pony compost. Manufactured fertilizer is normally produced using feed and smashed corncobs, in spite of the fact that the term frequently alludes to any mushroom manure where the prime fixing isn't horse compost. The two kinds of manure require the expansion of nitrogen supplements and a molding operator, gypsum.

Making Mushroom Compost

fertilizer readiness as a rule happens outside in spite of the fact that an encased building or a structure with a rooftop over it might be utilized. A solid chunk, alluded to as a wharf, is required for fertilizing the soil. Likewise, a manure turner to circulate air through and water the fixings, and a tractor-loader to move the fixings to the turner is required. In prior days heaps were turned by hand utilizing pitchforks, which is as yet an option in contrast to automated gear, however it is work escalated and physically requesting.

treating the soil is started by blending and wetting the fixings as they are stacked in a rectangular heap with tight sides and a free focus. Ordinarily, the mass fixings are put through a manure turner. Water is showered onto the pony fertilizer or manufactured manure as these materials travel through the turner. Nitrogen enhancements and gypsum are spread over the highest point of the mass fixings and are completely blended by the turner. When the heap is wetted and shaped, vigorous aging (treating the soil) initiates because of the development and generation of microorganisms, which happen normally in the mass fixings. Warmth, smelling salts, and carbon dioxide are discharged as results amid this procedure. Fertilizer activators, other than those referenced, are not required, albeit some natural cultivating books pressure the requirement for an "activator."

Mushroom manure creates as the synthetic idea of the crude fixings is changed over by the action of microorganisms, warmth, and some warmth discharging compound responses. These occasions result in a sustenance source most suited for the development of the mushroom to the avoidance of other organisms and microscopic organisms. There must be satisfactory dampness, oxygen, nitrogen, and sugars present all through the procedure, or else the procedure will stop. This is the reason water and enhancements are included intermittently, and the manure heap is circulated air through as it travels through the turner.

Gypsum is added to limit the oiliness manure regularly will in general have. Gypsum builds the flocculation of specific synthetic compounds in the manure, and they cling to straw or feed as opposed to filling the pores (openings) between the straws. A side advantage of this wonder is that air can saturate the heap all the more promptly, and air is basic to the treating the soil procedure. The prohibition of air results in an airless (anaerobic) condition in which pernicious synthetic mixes are shaped which diminish the selectivity of mushroom fertilizer for developing mushrooms. Gypsum is included at the beginning of fertilizing the soil at 40 lbs. per ton of dry fixings.

Nitrogen supplements as a rule use today incorporate brewer's grain, seed dinners of soybeans, peanuts, or cotton, and chicken fertilizer, among others. The reason for these enhancements is to expand the nitrogen substance to 1.5 percent for steed compost or 1.7 percent for manufactured, both registered on a dry weight premise. Manufactured fertilizer requires the expansion of ammonium nitrate or urea at the start of treating the soil to give the manure microflora a promptly accessible type of nitrogen for their development and multiplication.

Corn cobs are here and there inaccessible or accessible at a value viewed as over the top. Substitutes for or supplements to corn cobs incorporate destroyed hardwood bark, cottonseed structures, killed grape pomace, and cocoa bean bodies. The board of a fertilizer heap containing any of these materials is novel in the prerequisites for watering and the interim between turning.

The underlying fertilizer heap ought to be 5 to 6 feet wide, 5 to 6 feet high, and as long as fundamental. A two-sided box can be utilized to frame the heap (rick), albeit a few turners are furnished with a "ricker" so a container isn't required. The sides of the heap ought to be firm and thick, yet the middle must stay free all through Phase I treating the soil. As the straw or roughage relaxes amid treating the soil, the materials turn out to be less unbending and compactions can without much of a stretch happen. On the off chance that the materials turn out to be excessively conservative, air can't travel through the heap and an anaerobic situation will create.

Turning and watering are done at roughly 2-day interims, however not except if the heap is hot (145° to 170°F). Turning gives the chance to water, circulate air through, and blend the fixings, just as to move the straw or roughage from a cooler to a hotter zone in the heap, outside versus inside. Enhancements are likewise included when the ricks are turned, yet they ought to be included from the get-go in the fertilizing the soil procedure. The quantity of turnings and the time between turnings relies upon the state of the beginning material and the time essential for the manure to warmth to temperatures above 145°F.

Water expansion is basic since a lot of will avoid oxygen by possessing the pore space, and too little can constrain the development of microbes and parasites. When in doubt, water is meant the purpose of draining when the heap is framed and at the season of first turning, and from that point either none or just a little is included for the span of fertilizing the soil. On the last turning before Phase II fertilizing the soil, water can be connected liberally with the goal that when the fertilizer is firmly crushed, water dribbles from it. There is a connection between water, nutritive esteem, microbial movement, and temperature, and in light of the fact that it is a chain, when one condition is constraining for one factor, the entire chain will stop to work. Researcher see this marvel more than once and have named it the Law of Limiting Factors.

fertilizing the soil keeps going from 7 to 14 days, contingent upon the idea of the material toward the begin and its qualities at each turn. There is a solid alkali scent related with fertilizing the soil, which is generally supplemented by a sweet, rotten smell. At the point when manure temperatures are 155°F and higher, and smelling salts is available, concoction changes happen which result in a sustenance rather solely utilized by the mushrooms. As a result of the concoction changes, heat is discharged and the fertilizer temperatures increment. Temperatures in the fertilizer can achieve 170° to 180°F amid the second and third turnings when an alluring dimension of natural and compound movement is happening. Toward the finish of Phase I the fertilizer should: a) have a chocolate darker shading; b) have delicate, flexible straws, c) have a dampness substance of from 68 to 74 percent; and d) have a solid smell of alkali. At the point when the dampness, temperature, shading, and scent depicted have been come to.

Finishing the Compost

There are two noteworthy purposes to Phase II fertilizing the soil. Purification is important to execute any bugs, nematodes, bother organisms, or different irritations that might be available in the fertilizer. What's more, second, it is important to evacuate the smelling salts which framed amid Phase I fertilizing the soil. Alkali toward the finish of Phase II in a fixation higher than 0.07 percent is frequently deadly to mushroom generate development, in this way it must be expelled; for the most part, an individual can smell smelling salts when the focus is above 0.10 percent.

Stage II happens in one of three spots, contingent upon the kind of generation framework utilized. For the zoned arrangement of developing, manure is stuffed into wooden plate, the plate are stacked six to eight high, and are moved into an earth controlled Phase II room. From there on, the plate are moved to exceptional rooms, each intended to give the ideal condition to each progression of the mushroom developing procedure. With a bed or rack framework, the manure is put straightforwardly in the beds, which are in the room utilized for all means of the yield culture. The most as of late presented framework, the mass framework, is one in which the fertilizer is put in a bond square canister with a punctured floor and no spread over the manure; this is a room explicitly intended for Phase II treating the soil.

The manure, regardless of whether put in beds, plate, or mass, ought to be filled consistently inside and out and thickness or pressure. Manure thickness ought to take into account gas trade, since smelling salts and carbon dioxide will be supplanted by outside air.

Stage II treating the soil can be seen as a controlled, temperature-reliant, environmental procedure utilizing air to keep up the manure in a temperature go most appropriate for the de-ammonifying creatures to develop and recreate. The development of these thermophilic (heat-cherishing) living beings relies upon the accessibility of usable sugars and nitrogen, a portion of the nitrogen as smelling salts.

Ideal administration for Phase II is hard to characterize and most business producers incline toward one of the two frameworks by and large use today: high temperature or low temperature.

A high temperature Phase II framework includes an underlying purification period amid which the manure and the air temperature are raised to at any rate 145°F for 6 hours. This can be practiced by warmth produced amid the development of normally happening microorganisms or by infusing steam into the room where the manure has been set, or both. After sanitization, the manure is re-adapted by promptly bringing down the temperature to 140°F by flushing the live with outside air. From that point, the fertilizer is permitted to cool step by step at a rate of roughly 2° to 3°F every day until every one of the smelling salts is disseminated. This Phase II framework requires around 10 to 14 days to finish.

In the low temperature Phase II framework the manure temperature is at first expanded to about 126°F with steam or by the warmth discharged by means of microbial development, after which the air temperature is brought down so the fertilizer is in a temperature scope of 125° to 130°F territory. Amid the 4 to 5 days after purification, the fertilizer temperature might be brought down by about 2°F every day until the alkali is dispersed.

It is imperative to recollect the reasons for Phase II when attempting to decide the correct methodology and arrangement to pursue. One design is to evacuate undesirable smelling salts. To this end the temperature extend from 125° to 130°F is most effective since de-ammonifying life forms develop well in this temperature run. A second reason for Phase II is to expel any bugs present in the manure by utilization of a purification succession.

Toward the finish of Phase II the fertilizer temperature must be brought down to around 75° to 80°F before generating (planting) can start. The nitrogen substance of the fertilizer ought to be 2.0 to 2.4 percent, and the dampness content somewhere in the range of 68 and 72 percent. Additionally, toward the finish of Phase II it is alluring to have 5 to 7 lbs. of dry fertilizer per square foot of bed or plate surface to get productive mushroom yields. It is vital to have both the fertilizer and the manure temperatures uniform amid the Phase II process since it is alluring to have as homogenous a material as could be expected under the circumstances.

[TOP]

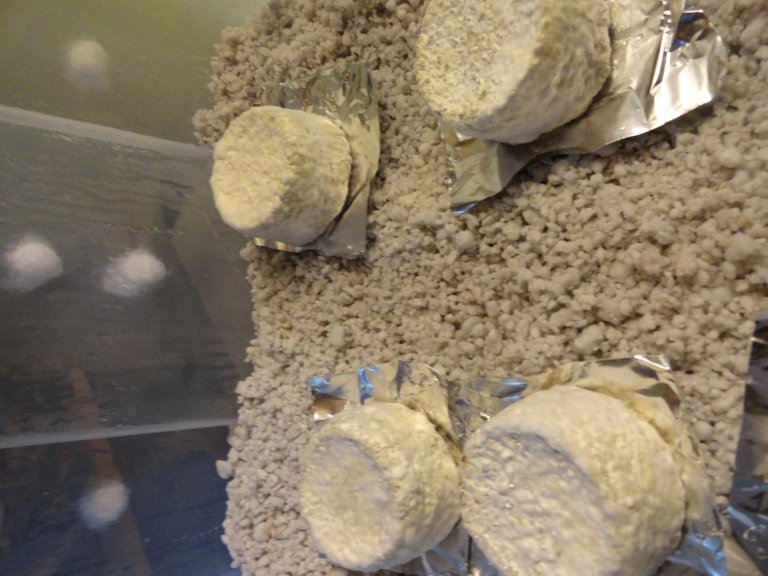

Spawning

Mushroom manure must be vaccinated with mushroom generate (Latin expandere = to spread out) on the off chance that one anticipates that mushrooms should develop. The mushroom itself is the product of a plant as tomatoes are of tomato plants. Inside the tomato one discovers seeds, and these are utilized to begin the following season's harvest. Minute spores structure inside a mushroom top, yet their little size blocks taking care of them like seeds. As the tomato originates from a plant with roots, stems, and leaves, the mushroom emerges from slim, string like cells called mycelium. Growth mycelium is the white, string like plant frequently observed on decaying wood or rotten bread. Mycelium can be proliferated vegetatively, such as isolating daffodil globules and getting more daffodil plants. Particular offices are required to spread mycelium, so the mushroom mycelium does not get blended with the mycelium of other organisms. Mycelium engendered vegetatively is known as produce, and business mushroom ranchers buy bring forth from any of around twelve bring forth organizations.

Bring forth producers begin the bring forth making procedure by disinfecting a blend of rye grain in addition to water and chalk; wheat, millet, and other little grain might be substituted for rye. Cleaned horse excrement shaped into squares was utilized as the development vehicle for produce up to around 1940, and this was called square or block bring forth, or compost generate; such bring forth is extraordinary at this point. When sanitized grain has a touch of mycelium added to it, the grain and mycelium is shaken multiple times at 4-day interims over a 14-day time of dynamic mycelial development. When the grain is colonized by the mycelium, the item is called generate. Bring forth can be refrigerated for a couple of months, so generate is made ahead of time of an agriculturist's organization for bring forth.

In the United States, mushroom cultivators have a decision of four noteworthy mushroom cultivars: a) Smooth white – top smooth, top and stalk white; b) Off-white – top flaky with stalk and top white; c) Cream – top smooth to textured with stalk white and top white to cream; and d) Brown – top smooth, top chocolate dark colored with a white stalk. Inside every one of the four noteworthy gatherings, there are different detaches, so a cultivator may have a decision of up to eight smooth white strains. The segregates differ in flavor, surface, and social necessities, yet they are largely mushrooms. For the most part, white and grayish cultivars are utilized for prepared sustenances like soups and sauces, yet all confines are great eating as new mushrooms.

Generate is disseminated on the manure and afterward completely blended into the fertilizer. For quite a long time this was finished by hand, communicating the bring forth over the outside of the fertilizer and unsettling it in with a little rake-like device. As of late, notwithstanding, for the bed framework, generate is blended into the manure by an extraordinary producing machine which blends the fertilizer and bring forth with tines or little finger-like gadgets. In a plate or clump framework, bring forth is blended into the fertilizer as it moves along a transport line or while tumbling from a transport into a plate. The bringing forth rate is communicated as a unit or quart for each such a significant number of square feet of bed surface; 1 unit for every 10 ft is alluring. The rate is at times communicated based on bring forth weight versus manure weight; a 2 percent producing rate is alluring.

When the produce has been blended all through the fertilizer and the manure worked so the surface is level, the fertilizer temperature is kept up at 75°F and the relative moistness is kept high to limit drying of the manure surface or the generate. Under these conditions the generate will develop – creating a string like system of mycelium all through the manure. The mycelium develops every which way from a bring forth grain, and in the long run the mycelium from the distinctive bring forth grains meld, making a produced bed of manure one organic element. The generate shows up as a white to blue-white mass all through the fertilizer after combination has happened. As the bring forth develops it creates heat, and if the fertilizer temperature increments to above 80° to 85°F, contingent upon the cultivar, the warmth may murder or harm the mycelium and wipe out the likelihood of greatest yield profitability and additionally mushroom quality. At temperatures underneath 74°F, generate development is impeded and the time interim among producing and reaping is broadened.

The time required for bring forth to colonize the manure relies upon the producing rate and its appropriation, the fertilizer dampness and temperature, and the nature or nature of the manure. A total produce run as a rule expects 14 to 21 days. When the fertilizer is completely developed with bring forth, the following stage underway is within reach.

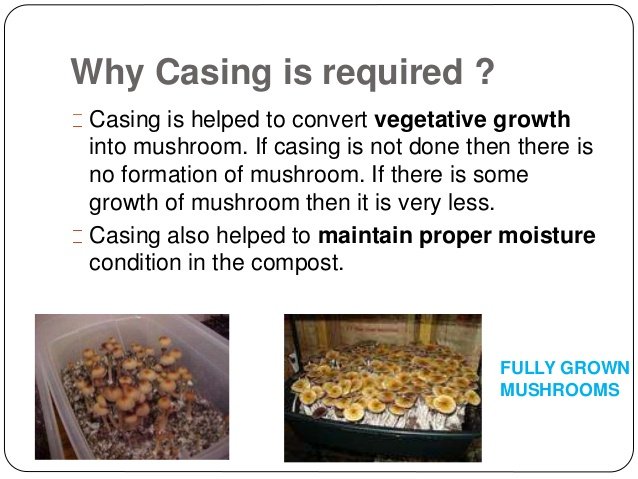

Casing

Packaging is a best dressing connected to the produce run manure on which the mushrooms inevitably structure. Mud topsoil field soil, a blend of peat greenery with ground limestone, or recovered endured, spent manure can be utilized as packaging. Packaging does not require supplements since packaging go about as a water repository and a spot where rhizomorphs structure. Rhizomorphs look like thick strings and structure when the fine mycelium intertwines. Mushroom initials, primordia, or pins structure on the rhizomorphs, so without rhizomorphs there will be no mushrooms. Packaging ought to be purified to dispose of any bugs and pathogens it might convey. Likewise, it is essential that the packaging be circulated so the profundity is uniform over the outside of the fertilizer. Such consistency enables the bring forth to move into and through the packaging at a similar rate and, at last, for mushrooms to create in the meantime. Packaging ought to almost certainly hold dampness since dampness is fundamental for the improvement of a firm mushroom.

Dealing with the yield in the wake of packaging necessitates that the fertilizer temperature be kept at around 75°F for as long as 5 days subsequent to packaging, and the relative mugginess ought to be high. From that point, the fertilizer temperature ought to be brought down about 2°F every day until little mushroom initials (pins) have framed. All through the period following packaging, water must be connected discontinuously to raise the dampness level to handle limit before the mushroom pins structure. Knowing when, how, and how much water to apply to packaging is a "fine art" which promptly isolates experienced cultivators from amateurs.

Pinning

Mushroom initials create after rhizomorphs have framed in the packaging. The initials are amazingly little however can be viewed as outgrowths on a rhizomorph. When an underlying quadruples in size, the structure is a stick. Pins proceed to extend and become bigger through the catch organize, and at last a catch augments to a mushroom. Harvestable mushrooms show up 18 to 21 days in the wake of packaging. Pins create when the carbon dioxide substance of room air is brought down to 0.08 percent or lower, contingent upon the cultivar, by bringing outside air into the developing room. Outside air has a carbon dioxide substance of about 0.04 percent.

The planning of outside air presentation is imperative and is something adapted just through involvement. By and large, it is best to ventilate as meager as conceivable until the mycelium has started to appear at the outside of the packaging, and to quit watering when stick initials are framing. On the off chance that the carbon dioxide is brought down too soon via airing too early, the mycelium quits becoming through the packaging and mushroom initials structure beneath the outside of the packaging. All things considered mushrooms keep on developing, they push through the packaging and are grimy at collect time. Too little dampness can likewise result in mushrooms framing beneath the outside of the packaging. Sticking influences both the potential yield and nature of a harvest and is a critical advance in the generation cycle.

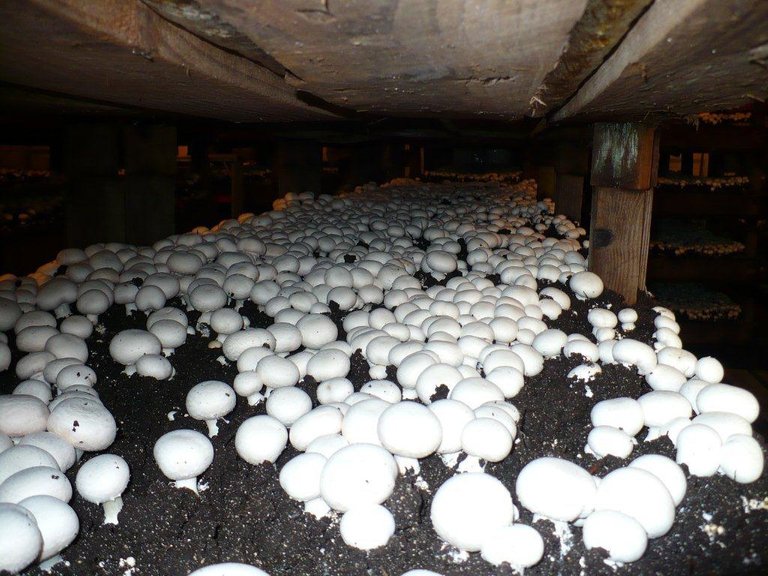

Cropping

The terms flush, break, or sprout are names given to the rehashing 3-to 5-day reap periods amid the editing cycle; these are trailed by a couple of days when no mushrooms are accessible to gather. This cycle rehashes itself in a cadenced manner, and reaping can go on insofar as mushrooms keep on developing. Most mushroom ranchers reap for 35 to 42 days, albeit some gather a yield for 60 days, and collect can continue for up to 150 days.

Air temperature amid trimming ought to be held between 57° to 62°F for good outcomes. This temperature go favors mushroom development, however cooler temperatures can stretch the existence cycles of both ailment pathogens and creepy crawlies bugs. It might appear to be odd that there are vermin which can harm mushrooms, however no harvest is developed that does not need to rival different living beings. Mushroom nuisances can cause all out yield disappointments, and regularly the central factor on to what extent to collect a harvest depends on the dimension of irritation pervasion. These pathogens and creepy crawlies can be constrained by social practices combined with the utilization of pesticides, however it is most alluring to avoid these living beings from the developing rooms.

The relative moistness in the developing rooms ought to be sufficiently high to limit the drying of packaging however not all that high as to cause the top surfaces of creating mushrooms to be damp or sticky. Water is connected to the packaging so water pressure does not frustrate the creating mushrooms; in business practice this implies watering 2 to multiple times every week. Each watering may comprise of more or less gallons, contingent upon the dryness of the packaging, the cultivar being developed, and the phase of improvement of the pins, catches, or mushrooms. Most first-time producers apply excessively water and the outside of the packaging seals; this is viewed as lost surface at the outside of the packaging. Fixed packaging keeps the trading of gases basic for mushroom stick development. One can gauge how much water to include after first break has been reaped by understanding that 90 percent of the mushroom is water and a gallon of water weight 8.3 lbs. On the off chance that 100 lbs. of mushrooms were collected, 90 lbs. of water (11 lady.) were expelled from the packaging; and this is the thing that must be supplanted before second break mushrooms create.

Outside air is utilized to control both the air and fertilizer temperatures amid the gather time frame. Outside air likewise dislodges the carbon dioxide radiated by the developing mycelium. The more mycelial development, the more carbon dioxide delivered, and since more development happens from the get-go in the yield, all the more outside air is required amid the initial two breaks. The measure of natural air likewise relies upon the developing mushrooms, the region of the creating surface, the measure of manure in the developing room, and the condition or sythesis of the outside air being presented. Experience is by all accounts the best guide with respect to the volume of air required, yet there is a standard guideline: 0.3ft/hr when the manure is 8 inches down, and of this volume 50 to 100 percent must be outside air.

An inquiry as often as possible emerges concerning the requirement for brightening while the mushrooms develop. Mushrooms don't expect light to develop, just green plants require light for photosynthesis. Developing rooms can be lit up to encourage gathering or editing rehearses, however it is increasingly basic for specialists or mushroom agriculturists to be outfitted with digger's lights as opposed to enlightening a whole room.

Ventilation is basic for mushroom developing, and it is likewise important to control dampness and temperature. Dampness can be added to the air by a virus fog or by live steam, or essentially by wetting the dividers and floors. Dampness can be expelled from the developing room by: 1) conceding a more noteworthy volume of outside air; 2) presenting drier air; 3) moving a similar measure of outside air and warming it to a higher temperature since hotter air holds more dampness and along these lines brings down the relative stickiness. Temperature control in a mushroom developing room is the same as temperature control in your home. Warmth can begin from boiling water coursed through channels mounted on the dividers. Hot, constrained air can be blown through a ventilation channel, which is fairly normal at all the more as of late fabricated mushroom ranches. There are a couple of mushroom ranches situated in limestone caverns where the stone goes about as both a warming and cooling surface contingent upon the season. Caverns of any kind are not really suited for mushroom developing, and relinquished coal mines have such a large number of characteristic issues to be considered as feasible locales for a mushroom ranch. Indeed, even limestone caverns require broad redesign and enhancement before they are appropriate for mushroom developing, and just the developing happens in the cavern with treating the soil occurring over the ground on a wharf.

Mushrooms are gathered in a 7-to 10-day cycle, however this might be longer or shorter relying upon the temperature, moistness, cultivar, and the phase when they are picked. At the point when develop mushrooms are picked, an inhibitor to mushroom improvement is evacuated and the following flush pushes toward development. Mushrooms are ordinarily picked when the shroud isn't excessively far expanded. Purchasers in North America need shut, tight, mushrooms while in England and Australia open, level mushrooms are wanted. The development of a mushroom is surveyed by how far the cloak is extended, and not by how expansive the mushroom is. Thus, develop mushrooms are both expansive and little, despite the fact that ranchers and customers alike favor medium-to vast size mushrooms.

Picking and bundling strategies frequently differ from homestead to cultivate. Crisply collected mushrooms must be kept refrigerated at 35° to 45°F. To delay the time span of usability of mushrooms, it is critical that mushrooms "inhale" after collect, so capacity in a nonwaxed paper pack is wanted to a plastic sack.

After the last flush of mushrooms has been picked, the developing room ought to be shut off and the room purified with steam. This last sanitization is intended to demolish any irritations which might be available in the harvest or the woodwork in the developing room, along these lines limiting the probability of pervading the following yield.

Conclusion

It takes roughly 15 weeks to finish a whole generation cycle, from the beginning of fertilizing the soil to the last steaming off in the wake of reaping has finished. For this work a mushroom cultivator can expect somewhere in the range of 0 to 4 lbs. per square foot; the national normal for 1980 was 3.12 lbs. per square foot. Last yield relies upon how well a cultivator has observed and controlled the temperature, stickiness, bugs, etc. Everything considered, the most critical factors for good creation seem, by all accounts, to be understanding in addition to a natural feel for the organic rhythms of the business mushroom. The creation framework used to grow a harvest can be picked after the fundamentals of mushroom developing is comprehended.