This Post is the continuation of one that I just published a few hours ago in the Architecture+Desing community, if you haven't seen it don't worry, you can understand this perfectly, I'm just telling you that if you want to know what originated the whole issue, you can go to the First Post and thus have all the context

Para Ponerlos rapidamente en situacion, estuve escribiendo sobre casas construidas con plastico reciclado, explicaba un poco las posibles cosas que se podian hacer con este sistema y tambien mencioné otras empresas dedicadas a temas similares. Originalmente iba a estar explicando mas en detalle como es que Conceptos Plasticos produce sus materiales y que es un bloque de plastico exactamente. Luego me di cuenta que eso podria insitar a las personas a investigar y hacer experimentos en casa, lamentandolo mucho hay muchos videos y foros donde no se habla a detalle de los peligros que esta practica conlleva y como minimizarlos y hacerlo correctamente, entonces explicaré el proceso que utiliza Conceptos plasticos y a su vez enseñaré lo que segun mi larga investigacion es la manera correcta de hacerlo en casa y asi si alguien siente la curiosidad, pueda hacerlo de manera responsable y adecuada.

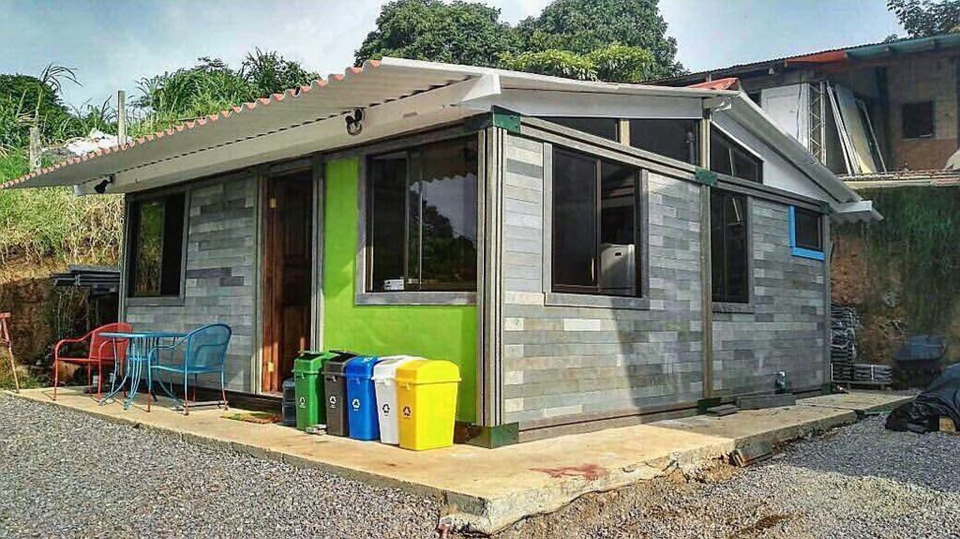

To put them quickly in situation, I was writing about houses built with recycled plastic, I explained a little the possible things that could be done with this system and I also mentioned other companies dedicated to similar topics. Originally I was going to be explaining in more detail how Conceptos Plasticos produces its materials and what exactly is a plastic block. Then I realized that this could encourage people to investigate and do experiments at home, regretting it very much there are many videos and forums where the dangers that this practice entails and how to minimize them and do it correctly is not discussed in detail, then I will explain the process that uses Plastic Concepts and in turn I will teach what according to my long research is the correct way to do it at home and so if someone is curious, they can do it responsibly and appropriately.

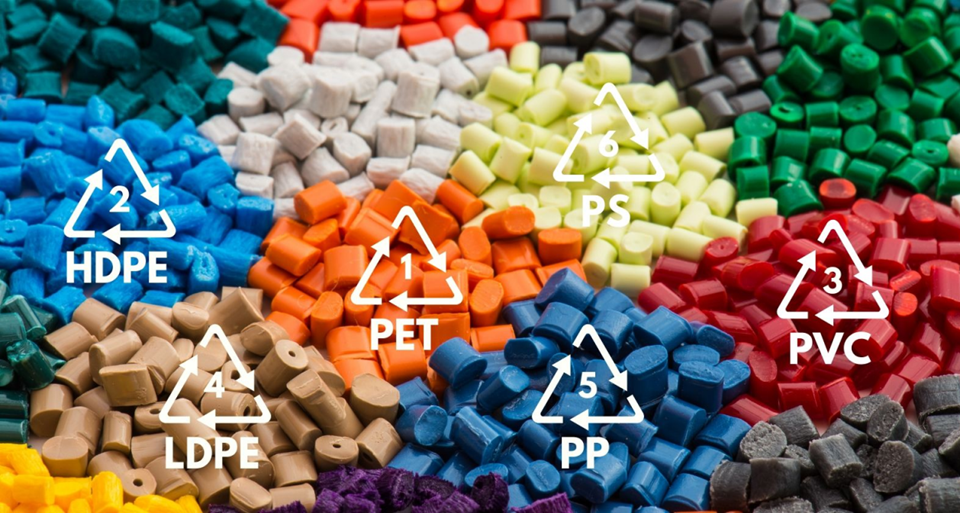

Lo primero seria conocer un poco sobre plasticos, es un tema extremadamente extenso que involucra mucho conocimiento avanzado sobre distintas ciencias, quimica en su mayoria. Aunque muy en resumen existen diferentes variedades de plasticos, provenientes no solo del petroleo, sino tambien del gas natural y algunos minerales naturales. De todos los que existe, hay solo 6 denominaciones de plastico que son principalmente conocidas por sus propiedades a la hora de reciclar. Se que son acronimos muy extraños y que parecen materiales que no estan al alcance de todos, dicho eso voy a nombrar 7 objetos que están hechos cada uno con un plastico de la lista y asi poder hacer notar que son mas comunes de lo que pensamos.

- (1) PET: Botella de Coca-Cola.

- (2) HDPE: Envase de champú

- (3) PVC: Tubos de agua (dentro de tu pared)

- (4) LDPE: Papel Film

- (5) PP: Tupperware

- (6) PS: Bandeja donde viene el Jamon rebanado

La informacion mas acertada, clara y resumida que encontré EN ESPAÑOL al respecto la consegui aca: (www.enestadocrudo.com/tipos-plastico/) dejo el link abierto para que no haya ninguna confusion, si tu idioma nativo es el ingles, tranquilo que mas adelante estaré nombrando otras fuentes que tambien lo explican igual de detallado en tu idioma.

The first thing would be to know a little about plastics, it is an extremely extensive subject that involves a lot of advanced knowledge about different sciences, chemistry for the most part. Although very in summary there are different varieties of plastics, coming not only from oil, but also from natural gas and some natural minerals. Of all those that exist, there are only 6 names of plastic that are mainly known for their properties when it comes to recycling. I know that they are very strange acronyms and that they seem like materials that are not available to everyone, that said I am going to name 7 objects that are made each with a plastic from the list and thus be able to note that they are more common than we think.

- (1) PET: Coca-Cola bottle.

- (2) HDPE: Shampoo container

- (3) PVC: Water pipes (inside your wall)

- (4) LDPE: Film Paper

- (5) PP: Tupperware

- (6) PS: Tray where the sliced ham comes

The most accurate, clear and summarized information that I found IN SPANISH about it I got here: (www.enestadocrudo.com/tipos-plastico/) I leave the link open so that there is no confusion, if your native language is English, calm down that later I will be naming other sources that also explain it as detailed in your language

El mayor peligro de fundir plastico en casa son los vapores emitidos al calentarse o al estar en contacto con algun material o sustancia quimica utilizada en el proceso, aunque lo mas comun es utilizar calor para un proceso de fundido, tambien llegué a ver procesos de fundicion por quimicos y si bien el plastico en general suele ser visualmente estable, su composicion quimica se va modificando al contacto con diferentes materiales o debido a cambios de temperatura. Un ejemplo muy comun y facil de encontrar es el caso de la Coca-Cola que posee un sabor diferente cuando está en botella plastica y en botella de vidrio (El vidrio no reacciona a los quimicos). Entonces como regla general, usar mascarilla y gafas de proteccion es lo adecuado y NECESARIO para trabajar con plastico, sin mencionar dejar una ventana abierta para que haya circulacion de aire.

The greatest danger of melting plastic at home is the vapors emitted when heating or being in contact with some material or chemical substance used in the process, although the most common is to use heat for a melting process, I also came to see melting processes by chemicals and although plastic in general is usually visually stable, its chemical composition changes when in contact with different materials or due to changes in temperature. A very common and easy to find example is the case of Coca-Cola that has a different flavor when it is in a plastic bottle and in a glass bottle (Glass does not react to chemicals). So as a general rule, wearing a mask and goggles is the proper and NECESSARY to work with plastic, not to mention leaving a window open for air circulation.

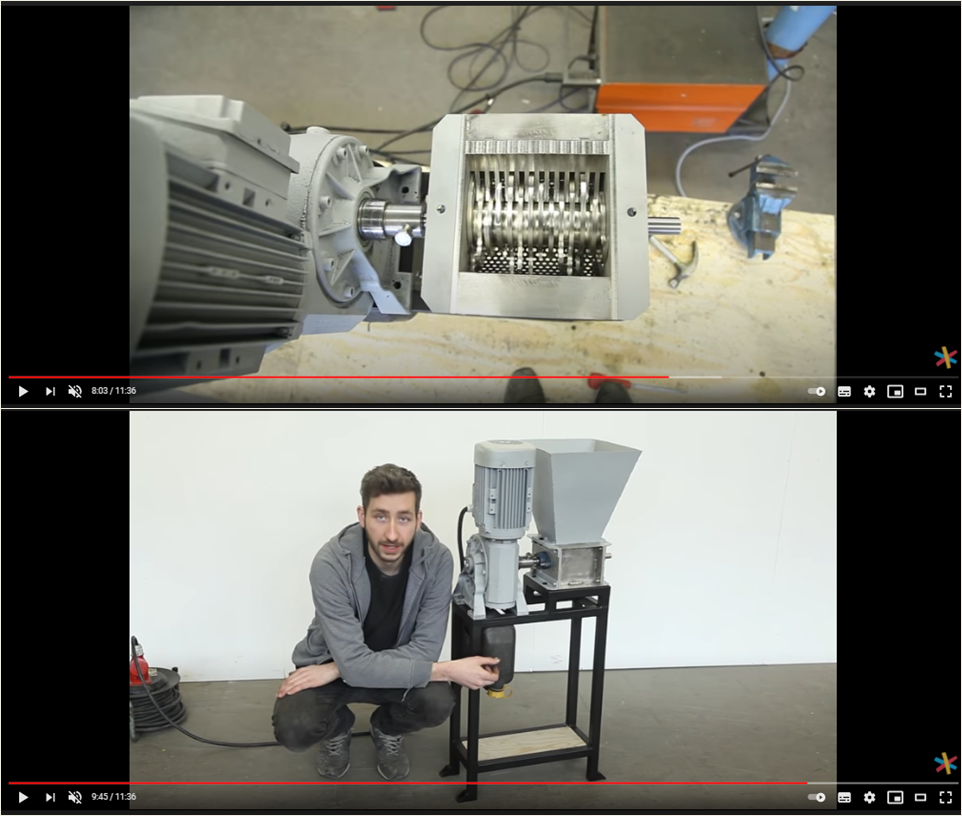

Luego de haber juntado o comprado el plastico que vamos a reciclar, el primer paso seria triturarlo para conseguir algo denominado Pellet, esto es simplemente pequeñas porciones de un material o sustancia. Para conseguir los Pellet lo ideal seria tener una trituradora como la que se ve en la imagen. One Army es el canal de Youtube con la comunidad mas grande en cuanto a este tema se trata y su comunidad tambien es bastante activa con videosy buscan soluciones mas economicas a sus inventos, por ejemplo utilizar en vez de un reductor mecanico utilizan plato y cadena de una bicicleta o un motor mas pequeño o lo he visto manual. Lo que si considero importante es utilizar este tipo de trituradora y no utilizar las alternativas que algunos muestran como colocarle una cuchilla a una amoladora o un taladro. En esos casos se manejan grandes velocidades y tanta energia y fuerza se vuelve peligroso e inestable. Entonces como recomendacion seria construir o comprar una trituradora como esta independientemente de que sea manual o mas pequeña, en caso de no tenerlo un par de tijeras tambien son utiles y mas seguras, aunque mucho mas lento. (El Link de la foto te mada directo al video)

After having collected or bought the plastic that we are going to recycle, the first step would be to crush it to get something called Pellet, this is simply small portions of a material or substance. To get the Pellets, the ideal thing would be to have a shredder like the one seen in the image. One Army is the YouTube channel with the largest community in terms of this issue and its community is also quite active with videos and they look for more economical solutions to their inventions, for example using instead of a mechanical reducer they use plate and chain. a bike or a smaller motor or I have seen it manual. What I do consider important is to use this type of shredder and not use the alternatives that some show, such as attaching a blade to a grinder or a drill. In those cases, great speeds are handled and so much energy and force becomes dangerous and unstable. So as a recommendation would be to build or buy a shredder like this regardless of whether it is manual or smaller, in case you don't have it, a pair of scissors are also useful and safer, although much slower. (The link in the photo will direct you to the video)

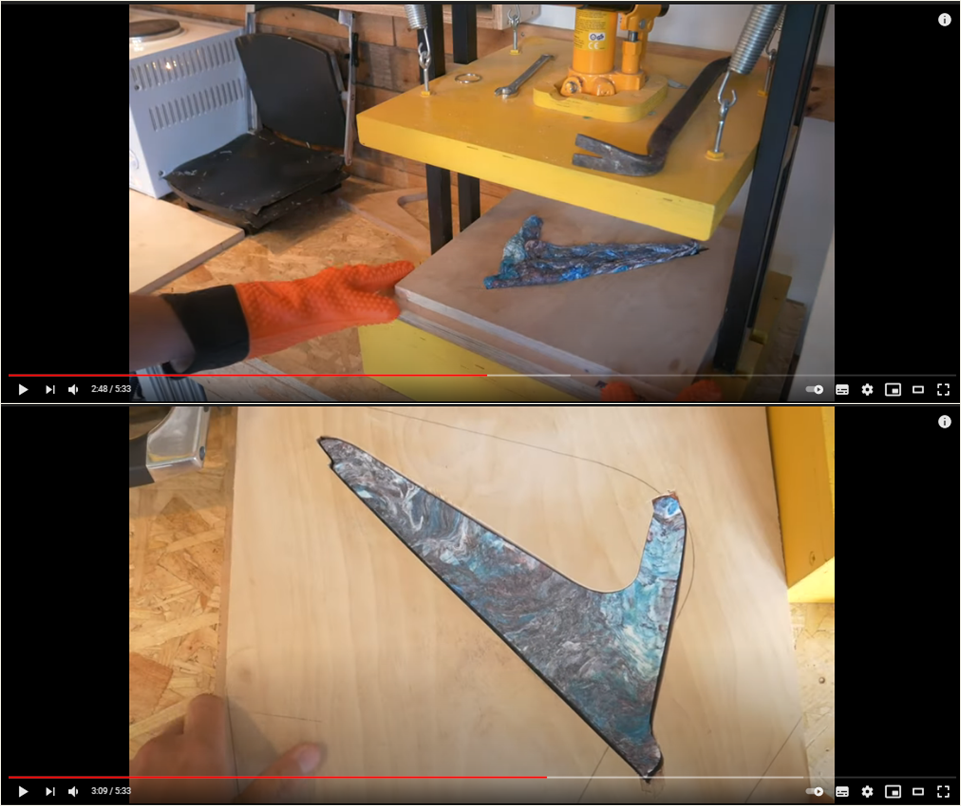

Brothers Make tambien es un canal que me resultó interesante, debido a que intentan llevar el tema de una manera un poco menos industrial y utilizando objetos que podamos tener en casa. Otra cosa que me pareció importante en este video en particular, es que hablan sobre la temperatura adecuada con la que se puede trabajar de forma segura el HDPE (2) y hacen recomentaciones bastante interesantes de seguridad. En el video tambien se vé como se omite el paso de triturar el plastico, lo cual da otra razon para no tener la necesidad de utilizar alternativas poco seguras para conseguir Pellet. El resultado es una plastico maleable como una plastilina que al enfriarse se vuelve completamente solido. (El link de la imagen te llevará a ese video)

Brothers Make is also a channel that I found interesting, because they try to carry the subject in a slightly less industrial way and using objects that we can have at home. Another thing that I found important in this particular video is that they talk about the proper temperature that HDPE can be safely worked with (2) and they make some pretty cool safety recommendations. In the video it is also seen how the step of crushing the plastic is omitted, which gives another reason for not having the need to use unsafe alternatives to obtain Pellets. The result is a malleable plastic like a plasticine that when cooled becomes completely solid. (The link in the image will take you to that video)

El siguiente paso luego de tener nuestro plastico en un estado similar a la plastilina seria colocarlo en un molde para luego comprimirlo. Volvemos a un video de Brothers Make, donde se muestra como un molde puede ser simplemente una tabla de madera hueca y en cuanto a la manera de comprimir el plastico, ellos utilizan una prensa hidraulica casera que ellos mismos construyeron, dicho eso, ese mismo modelo de prensa se puede construir con un gato mecanico, de los que tienes que girar una palanca para subir y bajar y tendras el mismo resultado, en caso de no tener las herramientas para hacerlo puedes utilizar una prensa de banco que es un poco mas pequeña y facil de encontrar, podrias utilizar mordazas o simplemente pararte sobre el molde un rato hasta que el plastico se enfrie lo suficiente. Es necesario dejar enfriar a temperatura ambiente al menos 2 horas, si añadimos agua fria para acelerar el proceso el plastico tiende a retraerse y no tendriamos la forma exacta de nuestro molde.

The next step after having our plastic in a state similar to plasticine would be to place it in a mold and then compress it. We return to a video of Brothers Make, where it is shown how a mold can simply be a hollow wooden board and as for how to compress the plastic, they use a homemade hydraulic press that they themselves built, that said, that same model The press can be built with a mechanical jack, of which you have to turn a lever to raise and lower and you will have the same result, in case you do not have the tools to do it you can use a bench press that is a little smaller and easy to find, you could use clamps or just stand on the mold for a while until the plastic is cool enough. It is necessary to let it cool at room temperature for at least 2 hours, if we add cold water to speed up the process, the plastic tends to shrink and we would not have the exact shape of our mold.

Si por alguna razon crees hacer algo una tabla plastica es poca cosa, tambien podrias comprar un molde por internet y empezar a hacer figuras que luego podrias pintar e incluso vender en forma de llavero por ejemplo. Para esto no necesitarias tener una maquina inyectora o algo por el estilo, simplemente tener algo de imaginacion para utilizar el mismo sistema de prensado manual. Existen muchos moldes como el de la foto de arriba, son moldes comunmente utilizados para mantequilla y pueden servir tranquilamente para nuestras obras en plastico, dicho eso, para un uso mas industrializado se suelen utilizar moldes de algun metal, debido a que son menos porozos por lo cual tendriamos una figura mucho mas lisa, sin mencionar que aguantan mejor la presion, la maderá por otro lado luego de unos 10 intentos aproximadamente empieza a perder sus bordes y nuestro molde empieza a perder eficacia. Una alternativa puede ser los moldes utiliados para Reposteria, son de metal y tiene una mayor variedad de figuras, aconsejaria hacer una base solida de concreto en la parte de abajo del mismo para que asi al momento de comprimir no haya ninguna deformacion en el molde debido a la presion.

If for some reason you think making something a plastic table is not enough, you could also buy a mold online and start making figures that you could later paint and even sell as a keychain for example. For this you do not need to have an injection machine or something like that, just have some imagination to use the same manual pressing system. There are many molds like the one in the photo above, they are molds commonly used for butter and can easily be used for our plastic works, that said, for a more industrialized use molds of some metal are usually used, because they are less pore per which would have a much smoother figure, not to mention that they withstand the pressure better, the wood on the other side after about 10 attempts begins to lose its edges and our mold begins to lose effectiveness. An alternative can be the molds used for Pastry, they are made of metal and have a greater variety of shapes, I would advise making a solid base of concrete at the bottom of it so that when compressing there is no deformation in the mold due to to pressure.

Y volviendo al principio, de una manera SIMILAR aunque mas indistrualizada es como Condeptos Plasticos produce sus bloques plasticos para la contruccion de viviendas a bajo costo que vimos en el Post anterior. Con esto no quiero pedirte que te pongas a construir una casa, solo te pediria que antes de botar una botella plastica, pienses detenidamente si la puedes utilizar para un proyecto y publicarlo en esta comunidad, estuve viendo y la mayoria de personas hablan de reciclar y utilizan rollos de papel de baño o carton y no me mal entiendan si es reciclar, aunque si lo haces por ecologia es mucho mejor reciclar plastico que carton que es material biodegradable, por otro lado, desde el punto de vista economico, si haces una figura plastica tendras un proceso de aprendizaje mas rico y seguramente tu Post tendria mayores recompensas y tu producto tendria mas posibilidades de ser vendido, y en caso de que nadie lo compre puedes guardarlo sin temor a que se estropee por humedad por ejemplo.

And going back to the beginning, in a SIMILAR way, although more undistrualized, is how Condeptos Plasticos produces its plastic blocks for the construction of low-cost houses that we saw in the previous Post. With this I do not want to ask you to start building a house, I would only ask that before throwing away a plastic bottle, think carefully if you can use it for a project and publish it in this community, I was watching and most people talk about recycling and They use rolls of toilet paper or cardboard and don't get me wrong if it's recycling, although if you do it for ecology it's much better to recycle plastic than cardboard that is biodegradable material, on the other hand, from an economic point of view, if you make a figure Plastic you will have a richer learning process and surely your Post would have greater rewards and your product would have a better chance of being sold, and in case nobody buys it you can save it without fear of being damaged by humidity for example.

Por ultimo, decir que es un tema realmente extenso, estamos hablando de que se pueden fabricar adoquines, tablas y utilizarlas como madera, juguetes, herramientas.. Que tal un set de llaves hechas con plastico reciclado? Las llaves de metal son relativamente caras, hacer un equivalente de plastico solido para trabajos pequeños seria una alternativa economica de solucionar un probema. Yo no te quiero vender la idea de "Salvar el mundo es necesario" sino algo mas enfocado a "Salvar el mundo te ahorra dinero y hasta produce ganancias".

Finally, to say that it is a really extensive topic, we are talking about that you can make paving stones, boards and use them as wood, toys, tools ... How about a set of keys made with recycled plastic? Metal wrenches are relatively expensive, making a solid plastic equivalent for small jobs would be an inexpensive alternative to solving a problem. I don't want to sell you the idea of "Saving the world is necessary" but something more focused on "Saving the world saves you money and even produces profits."

Originally in this Post I was going to talk about numbers and prices and everything environmental, I have run out of space, so very possibly there is a third and last part strictly related to costs, times and profits of working with plastic, if I decide to do it, I will leave it in one of the comments of this Post

Congratulations @randomproject123! You have completed the following achievement on the Hive blockchain and have been rewarded with new badge(s) :

Your next target is to reach 4500 upvotes.

Your next target is to reach 300 replies.

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPCheck out the last post from @hivebuzz:

Support the HiveBuzz project. Vote for our proposal!