'' Plastic could be our friend. The boy takes around 450 years to decompose... why don't we reuse those that have already been produced? ''

Yo Ciao Ciao SurfHive! Good morning, All good? :)

Today a beautiful day dawned here in southeastern Brazil, so i'm going to share with you a project I carried out with @preciousplastes , #AirdropCulture and #Arte8ciclagem.

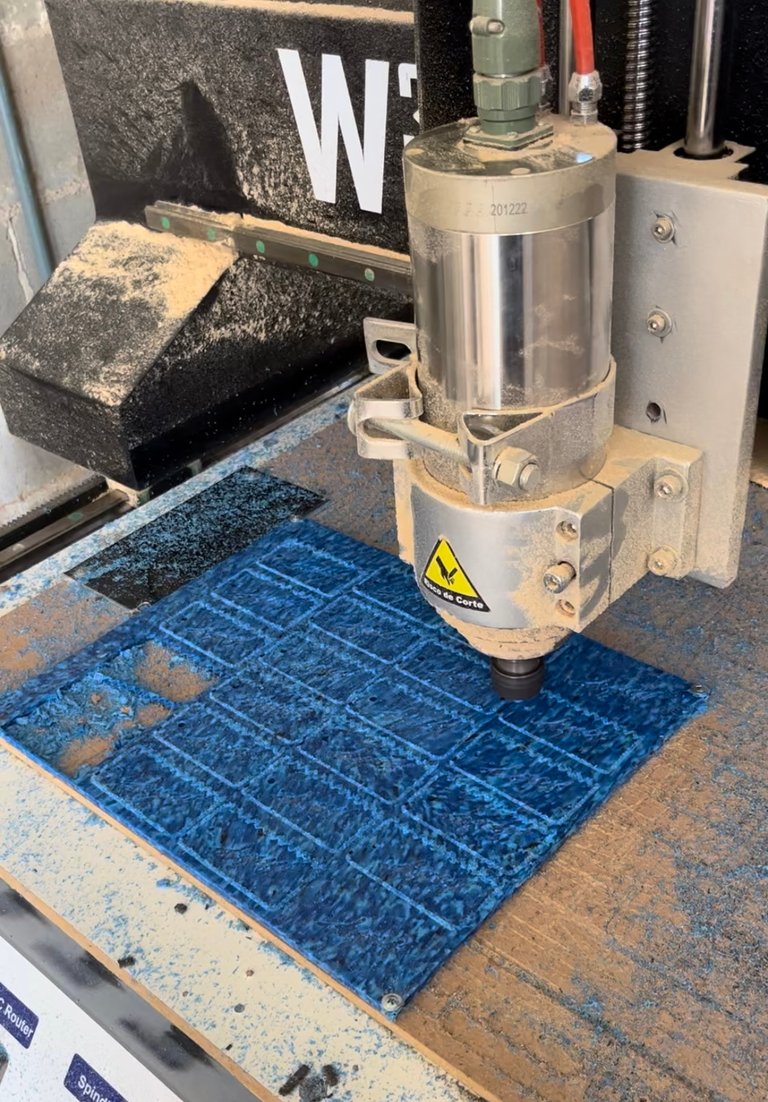

Wax Scraper

This was a project that we had wanted to develop for a while. I remember seeing Precious Plastic Melbourne doing something similar... and damn, i believe most of wax scrapers on the market come from a not very healthy trade industry. So, I decided to stay away from that path when developing this product for Airdrop Culture. I gave my friends at Precious Plastic a shout out and we started to scope out the project.

1 First Step (Plan)

We decided to produce the Airdrop Culture scrapers due to the launch of the Surf Shorts, so that it would be alongside the NAVY, Ocean Model that was already on the way. We didn't have enough time to design and order the mold for the injection molding machine. So, future plan, let's go with what we have at the moment, frugality.

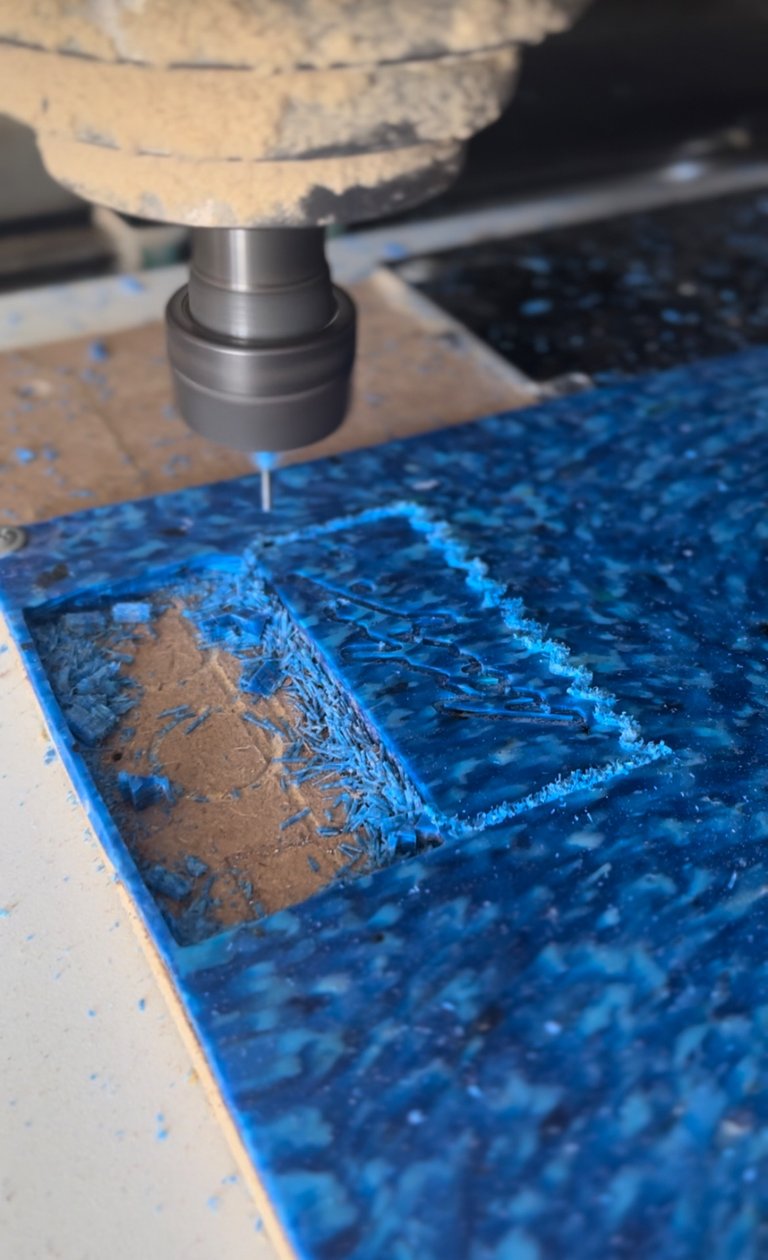

We got in touch with comrade Felipe from arte8reciclavel and checked which plates he had in stock for ready delivery in a palette similar to Bermuda Navy's Ocean strip, and we found the blue plate, recycled from plastics such as water bottle caps, which stopped us It already made even more sense, so Felipe helped us big time as always!

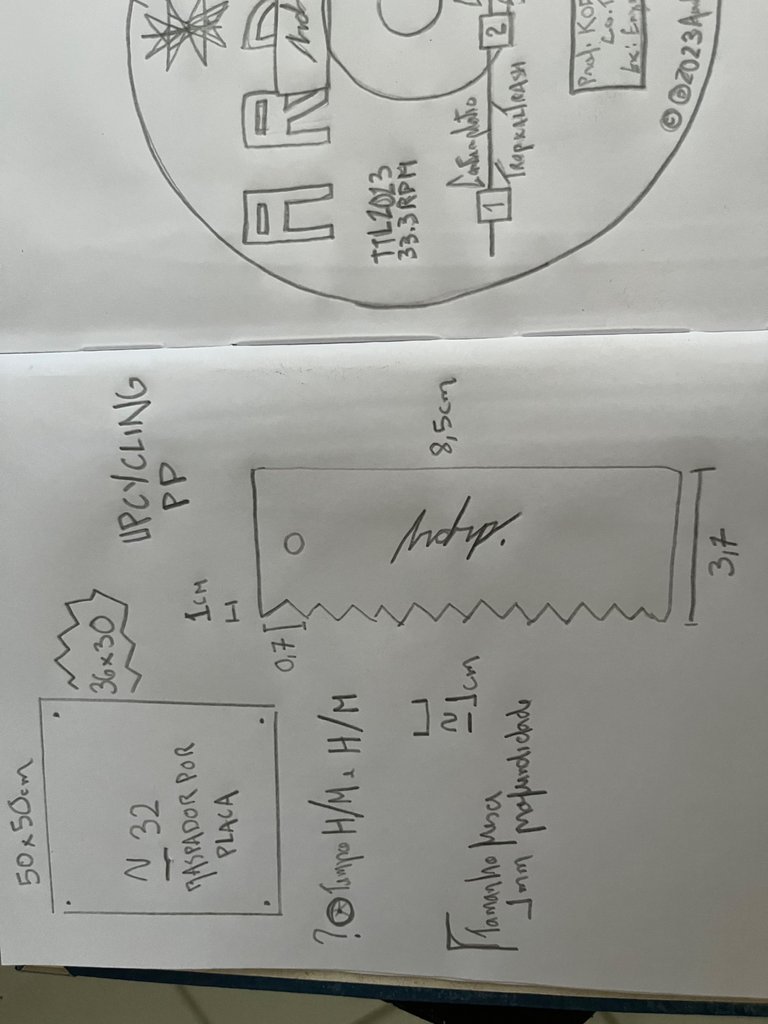

2 Second Step (Skeetch)

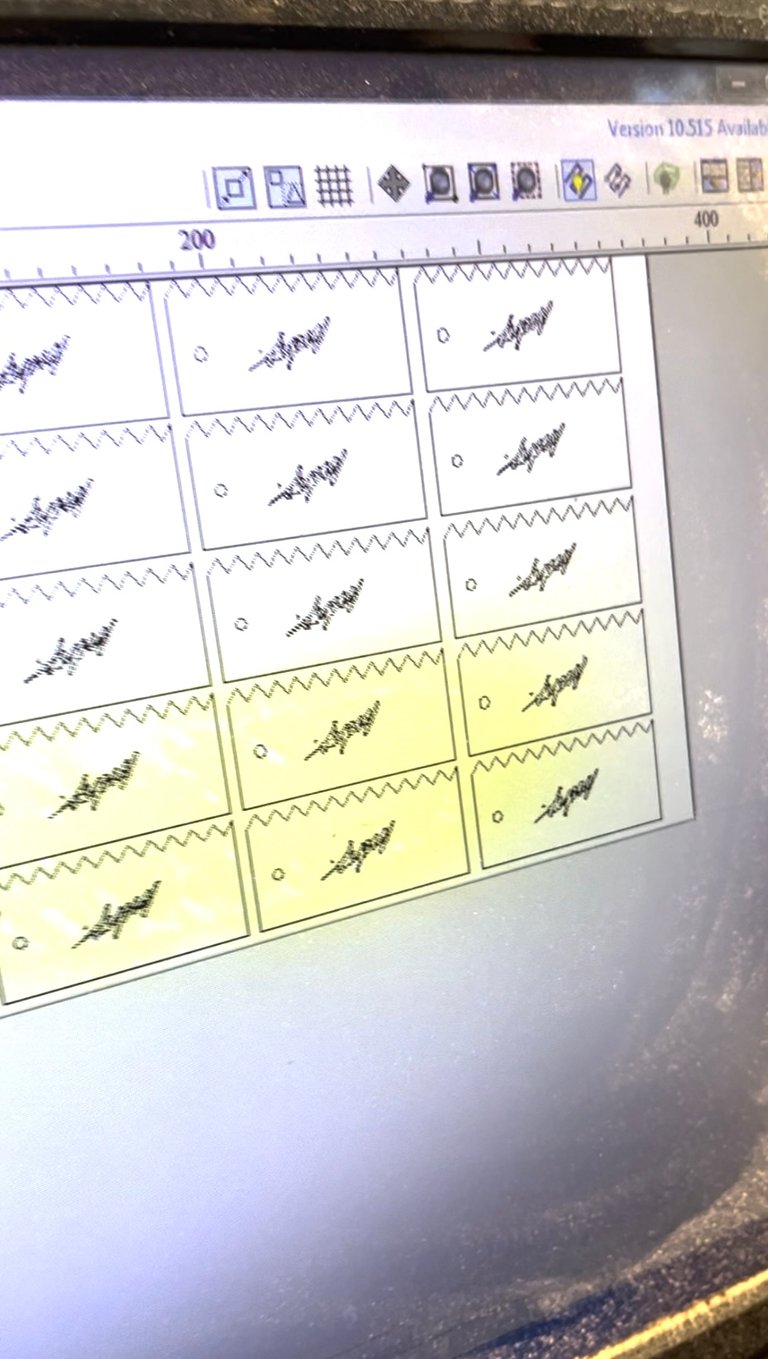

I drew the scraper model we wanted on paper, with the appropriate number of teeth, with spacing and height following an execution plan from CNC Route. I drew the scraper model we wanted on paper, with the appropriate number of teeth, with spacing and height following an execution plan from CNC Route. And this consists of calculating the dimensioning of the plate considering a minimum spacing of 1.5 cm for the screws on the four ends of the plate.And fit our previously prototyped scraper design from paper to digital technical drawing. "Babao" #busato kind of surfer nerd help a lot in this part of process.

3 Third Step (Chiquim)

I sent a message to an old friend "Chiquim" to continue the project. Chiquinho must be around 50 years old, lives in the interior of Espirito Santo and is a super good guy. There's a factory where his son works, "Devyd", there we started developing ideas a while ago. So why don't they help us with this?

Then we started the mess! Whenever we go there we do some crazy drawings and the main project, as at the moment, is "The Scraper."

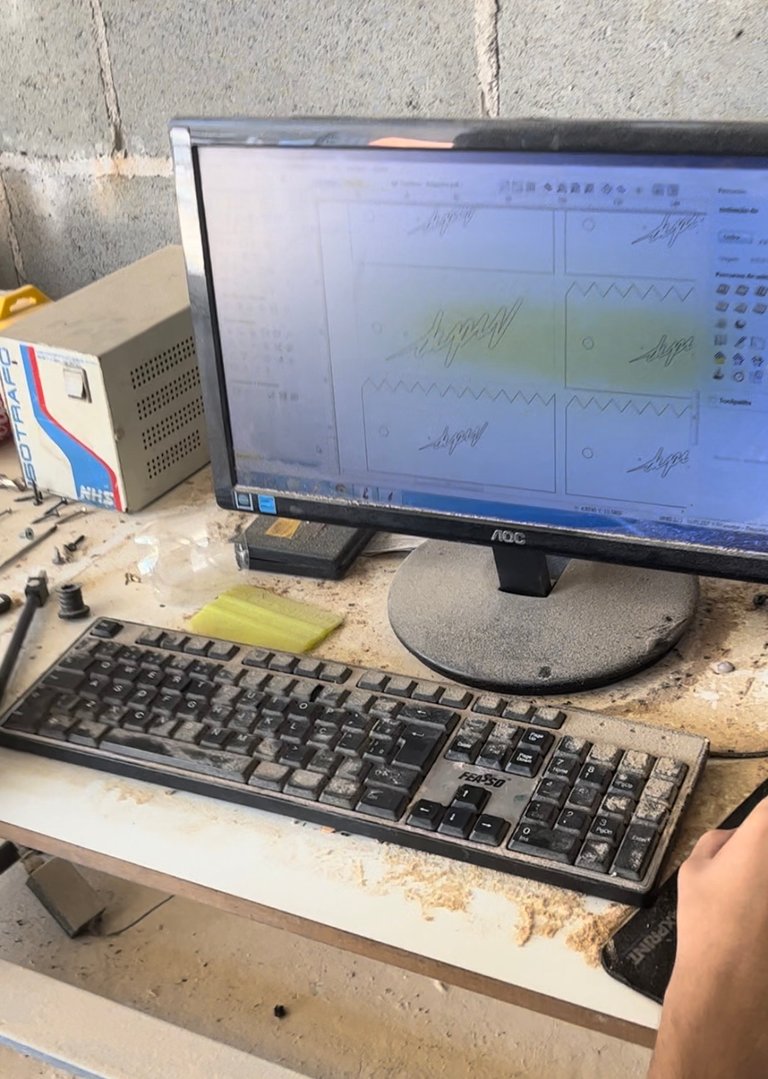

The CNC Route machine costs per hour, so we always try to arrive as prepared as possible for work efficiency.

After the scope of scrapers was properly fitted to the machine for the first test, I realized that there was already something wrong in terms of design, but I needed to think about the product in a more physical way. When the result came out, we saw that the contours were 100% square and the size of the logo was relatively small, not minimalist in appearance, but almost ineligible. So we decided to change.

FINAL PRODUCT

FIRST TRY (RUSTIC AND SQUARE)

The change consisted of rounding the top of the object, creating a more harmonious and delicate design, just as we also increased the size of the ARDRP logo.

Before giving the final command to automatically execute the machine, we decided to carry out another test on the code on the logo, which would not be 1mm deep in the outline but rather a larger cutter with 1.5mm depth filling the entire logo.

And now... yes! We arrived at our final result…

4 Four Step (NAVY)

The ARDRP shorts for SURF practice come with the Blue Ocean scraper. It was a somewhat short-notice project, but I think the love we put into our development ends up showing us a path to execution within the limitations. And things move forward.

The scraper has been tested by customers/friends and collaborators, and it's great to see how people are impressed and feel good about using a simple accessory like the scraper, when it comes from a valuable job like upcycling.

We are already thinking about the next scraper model... will it follow the same line of development? Wait :)

One thing I guarantee, it will be made from recycled plastic.

I hope you liked the post guys. ALOHA!

Save the Planet 💙

That looks awesome! Well done on a great recycled product!

Thank you my bro! Always ✌🏼💪🏾♻️

You took recycling to the next level, looks amazing!

Yo thank u Gabriela! It's been amazing try some new projects with @preciousplastes :) good way ✌🏼

Nice job guys!! well done! I want one 😜👀

Iuuuu! Aloha familia. Vou separar um para você 💪🏾✌🏼

🌱✨

S2 s2 s2

Good productive project. Recycle. Greetings.

Grazie!!! The plan is still trying some others lines and products around surf and fashion industry... a lot of plastic around that. 🙏☀️