All pictures taken by and owned by me - This is me in full PPE(Pre-Covid) on some ship somewhere.

It is Sunday morning, the work week starts again tomorrow. I would like to take this opportunity to share with you all what I do for a living. I actually fulfill several roles at the company that I work for. I was not initially hired to do any of these things but they became my job through constantly being willing to adapt to the situation and thus I have acquired the many hats that I now wear.

The toolbox, the Tradesman' bread and butter

I am pleased to have found #STEMGeeks, as I was looking for a place to post this kind of content.

On to cases...

I was originally hired to become a BMS Technician. In a nutshell, Airconditioning equipment can be linked up to PCs and entire Buildings can have all their systems displayed in a central location and controlled remotely. Often these computers are then connected to the internet and a controls technician can dial in and check the systems for faults.

A running V-Belt arrangement, driving a scroll fan.

I was hired to do this job because I already had a practical background and experience with computers while many of the existing technicians of the company do not habitually touch a PC. Perhaps that is why there is a bit of a gap. Surely there are some people who bridge this gap between mechanics and computers?! Possibly other BMS and Controls Technicians!

Rigging in of a Cooling Tower on a rainy day. All went well!

I was placed as an Assistant to a qualified Refrigeration Technician, who started to teach me some of the basics about the machines. I already had picked up some rudimentary skills in hand tools from my 2-year stay in Orania - a small pioneer-like town where anyone might end up doing any kind of work. Here I diversified my skills greatly and it is what gave me an additional foot in the door towards what I am doing now.

A person who knows his way around PC hardware and software AND knows the difference between a ratchet spanner and a pipe wrench? Great!

A Chilled water system in the process of being insulated with PIC.

Very soon after being an assistant (2 weeks), I had my first taste as to what it is like to work at the Docks. In Cape Town Harbour, there are many docks and companies that offer repair services to the vessels in the harbour. One such company was DCD Doorbell, they had the contract to do refurbishment of a European-owned Oil Rig, which was being serviced in Cape Town. DCD hired ACS to do the Accommodation works who in turn hired our company to do the Air-conditioning and Refrigeration.

I was enlisted here for the menial, though tricky task of allocating specific wire numbers to cables that were connected between the distribution panels and the cabins, as well as between the diffusers (a kind of air vent) and the thermostat (controller dial on the wall). Each and every cabin had its own unique numbers on each wire inside the cable. This was all mandated by the client, who wished such details for their own internal manuals.

The total scope our company was involved in on this project was massive and much more complicated than the job I was busy with. Once our work was completed, I was sent on a BMS training course. I also was placed on servicing duty at various locations.

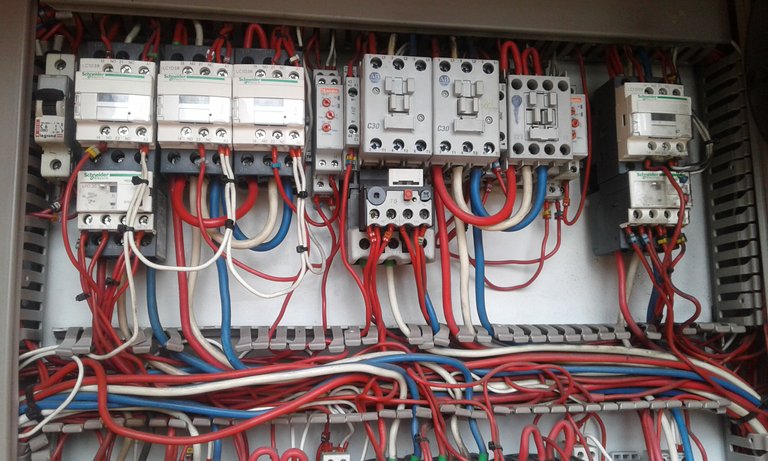

An average electrical panel found on site - not built by us! Ours is better!

Around 7 months into my employment during 2014, there was a situation that changed my life forever.

Our company had gotten more work to be done than we had supervisory staff to manage. One of the technicians was doing Offshore work in Angola and was unable to attend a site that would have 8 staff members he would need to manage.

The client needed us to begin our work as soon as possible as our work would be affecting their entire project plan.

Thus the management had to rely on some new blood to stand in as a site manager just for 2 weeks until the other Technician could return to South Africa.

The site had a big Health and Safety element to it, which also affected my future trajectory in life and position in the company.

A Self-lock Scaffolding being erected to gain access to an aircon unit.

By the time the Technician who was meant to be the supervisor for this job had returned to South Africa, the company had gained full confidence in my ability to run a work site. I had a supervisor that would drive to the site from time to time. It was his job to oversee many sites. He came to me once a day or sometimes skipped a day in between. By the last third of the project, he would only visit me twice a week.

Once this job was done, there was another even bigger project that needed to be done and again I was chosen to manage this site. This project was so large that my supervisor was appalled at the prospect, saying that I did not yet have the experience for the job.

However, the owner had confidence in me and the supervisor was still placed in a consulting role on site. Despite that argument(which was a little more colourful than I am telling you here), I managed to build a good relationship with my supervisor. I assured the man that he would indeed still be planning and managing this site, but that it would be my job to execute the tasks.

He would give me the overall instructions of what needed to be accomplished and it was my job to administrate my human resources and stock to accomplish those goals.

Condensor Units on the roof of a Mall - Always label these correctly!

I am not going to go into too much detail about these projects right now.

After this, there was a new question posed to me: Would I like to do a course on Health and Safety?

The answer to "Do you want to do a course?" from your employers should always be answered with "Yes, please!"

The gist of the matter was that at each project, the company would have to pay thousands of Rands to a qualified Safety Officer who came to the site once or twice, gave us a Safety File with a signature in the right place, and the rest we needed to do ourselves.

This practice was becoming insufficient for many clients and thus it gave the company two choices: Either hire a Health and Safety professional full time or train one of their full-time staff into being a Health and Safety professional.

Since I was willing to learn, this is what happened.

After some time I also managed to make my way into a Learnership program which is required to qualify as an Industrial Refrigeration Technician.

As it stands today, I am the Company's Health and Safety Officer. I hold membership with SAIOSH (South African Institute of Safety and Health) as a Tech SAIOSH(Technical Member) and am registered as an OSHPrac. (Occupational Safety and Health Practitioner). I also hold a membership with SACPCMP (South African Council for the Project and Construction Management Professions) as a CHSO (Construction Health and Safety Officer).

I have also completed my NQF2 and NQF3 years of Industrial Refrigeration trade but still, need to get my trade test (red seal) certification.

In my run-of-the-day work week, I do Health and Safety. I prepare files, write Method Statements and Risk Assessments. I inspect things, record the inspections, and scan and file away the digital and paper copies of these inspections.

I go to sites to assess the working conditions and to check that our staff are being compliant with the rules.

At the drop of a hat, I may however be called out. In an emergency, an additional technician is required on a site. Or a service team may be short a technician and I go to assist so that the workflow of our service work does not slow down.

Less frequently, yet regularly there will be some larger work that requires a site establishment. This means a fenced-off area and some containers for storage, an office container, and some sort of toilet.

Me at the docks, post Covid

This is where I am called in to get involved because whether this is a job site regarding a ship in the harbour or a building on the land, there is a hard-hat and safety boots environment and that means both Project Management and Health & Safety.

So, yes, a person can describe me as having many hats and this often puts me into a situation where different departments of management are fighting for my time. It also means that my time at work is often scrutinized as I cannot afford to be wasteful with my time.

Even when the company is relatively quiet, my work never ends. I remain busy at a frantic pace because, by the time I am done with one set of work, another job, work, or task opens up for me to get involved in.

That is a broad overview of what I do and what I am involved in. Perhaps I will cover more posts regarding some of the more technical aspects of the HVACR trade in the future.

Cheers for now!

This is quite interesting taking us through your profession. We are both hands on kind of guys by the looks, everyman should own a toolbox 🧰 😃😃

I've had to do Health and Safety course over and over myself since the certificate expires every 2-4 years.

Keep doing what you do whike stacking up those cryptos!

You know it man! I've been very busy. Yesterday for half of the Saturday I was at a training course for SARACCA Safe Gas Handling.

What do you do tools-wise?

I am in the telecommunication industry, install antenna system to boost network coverage for MTN, Vodacom...

So when it comes to mounting remote units on wall, am familiar with torque wrench, spanners, socket sets...

I enjoy using tools and especially when you are good with tools you enjoy the job.

Indeed. There was a time before I learned how to work with tools, I was just in retail and working with computers, I knew nothing about tools.

Certain tasks seemed impossible feats that would require the intervention of experts. Today I can look at something and I know I can fix it, alter it or build it. The world has a lot more options now.

Very true, you tend to see solutions to problems instead of backing of and seeing solutions to problems.

I am very much trained to be a solutions man 😄

Lol it comes with a mindset as well, one of the reasons we find ourselves involved in crypto

The different classes of expertise that are yours are very rare, and you seem to accumulate even more skills with time. Wow! Cheers!

PS: I envy your toolbox. Mine has nice tools in it, but not as nice (but this is sufficient for fixing things at home ;) ).

Haha. Thank you for your kind words. There are some technicians who I look up to as inspiration. One, in particular, seems to always modify and improve any kind of tool he gets his hands on.

That is how we move forward I guess. I actually have a test to study for again.

Good post 😃

!PIZZA

Thank you very much!

Very Interesting. Thanks for the overview. I have done a lot of construction work and the average person doesn't realize how much thinking about different factors and outcomes can can go into even the seemingly simplest of jobs. I have often worked for people with college degrees that look down on someone who works with their hands but can't grasp the basics of the physical world. I had a job once where someone who was making way more money than me wanted me to change a light bulb in their living room. I grabbed a chair and changed the bulb. The task was beyond their problem solving abilities. Best of luck to you.

PIZZA Holders sent $PIZZA tips in this post's comments:

@bernaku(1/5) tipped @zakludick (x1)

You can now send $PIZZA tips in Discord via tip.cc!