As many of you know, farming is a water-intensive activity especially when you have several acres of land and crops that demand constant watering - in this case, tamarillos.

You simply cannot go a day without water lest the fruits start dropping to the ground due to water stress.

They are spoiled, what can I say?

Our source of water is a river 240 meters downhill way over on the other side of the farm.

It is part of the farm but it is not fenced, therefore, it remains accessible to everybody in the area.

That naturally poses a security risk when it comes to the relatively expensive water pump hence the need for a well-secured pump house built with thick slabs of concrete and heavy steel doors.

The pump house has stood firm despite some attempts in the early days by some curious miscreants who tried to pry the doors loose. They failed.

The water pump lasted only 5 months before it broke down - a first. They normally last at least a year before they breakdown.

We theorized it could have been as a result of the heavy rains that had hit the area over the months of March, April, and May that must have loosened coarse debris that could have been sucked into the pump and worn out the moving parts.

Unfortunately, there wasn't any time to spare for a thorough diagnosis of the problem so we had to spend another $1000 on a new pump which was sent over using courier services from Nairobi's Davis and Shirtliff.

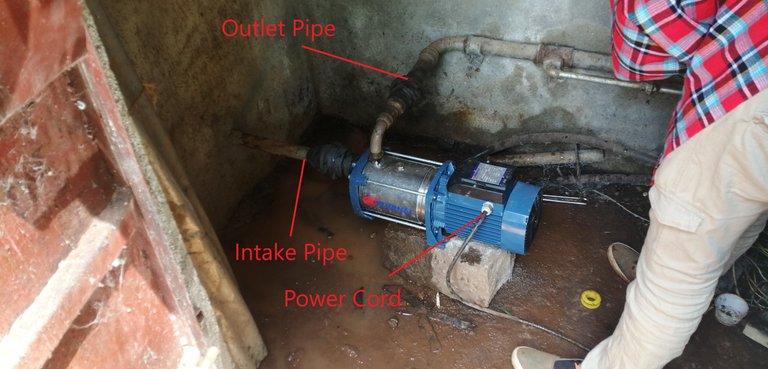

Now, the process of installing the new pump was relatively straightforward.

- Hook up the power cord to the correct terminals on the pump. Live, Earth, and Neutral.

- Run a quick 'on and off' test to see if power is being received by the machine.

- Take down the damaged pump from the plumbing and hook up the new pump. This needed a bit of technique and angling to get it in place.

- Finally, prime the pump by letting the back-flow from the outlet pipe into the pump to get rid of any air.

- The intake pump was also fitted with a double layer thin mesh box, then further housed inside a larger mesh to filter large debris thus protecting the pump. (We hope this will boost the life of this pump.)

When all that was done, we let her rip.

The pump came alive with a bit of a sputter and shudder as the water came flooding into the pump from the river through the intake pipe.

But before we could pump it up the outlet to the storage tank on the farm by means of opening the outlet valve, we had to allow the pump to cycle through and remove all the air in the system for optimum water pressure.

That is done via the 'exhaust'.

Basically, a short pipe running through the back of the pump house that dumps water which then flows all the way back to the river due to gravity.

In the first cycle, the pressure was weak but three or four cycles later we had hit equilibrium and the water pressure maxed out as expected which is demonstrated by the water hitting our stick marker. (The marker was set by previous identical pumps when they were new.)

Can you spot the obvious difference?

That was it.

The outlet valve was opened and the exhaust valve was closed allowing the water to shoot up the steep incline, 240 meters up into the large water storage tank on the farm.

In conclusion, the modification to the intake is one of the main changes we made to the pumping process. Grit or small particles of sand can get into the moving parts of the pump destabilizing them.

The pump can, therefore, not maintain consistent/strong water pressure hence its ability to pump water degrades over time eventually failing especially if it is pushing water up a steep incline like what we have.

You can also account for the weight of the water in the outlet pipe pushing back against the pump because the machine is not strong enough to push it up the hill.

The final solution is probably sinking a well in the main compound but that would cost well over $10,000. With the coronavirus pandemic still being a genuine threat to income sources that would be too much of a risky investment in the short term.

Here is to hoping things get better and to move to a more recognizable normal before the year's end!