There are companies that have a history in the oil sector because they have always innovated with the incorporation of new technologies that help the oil industry to minimize costs and to be able to actively continue with the exploration and production activities of hydrocarbons.

For this case that I come to explain is the contribution of the company Halliburton, which presents in an innovative way the first intelligent fracturing system.

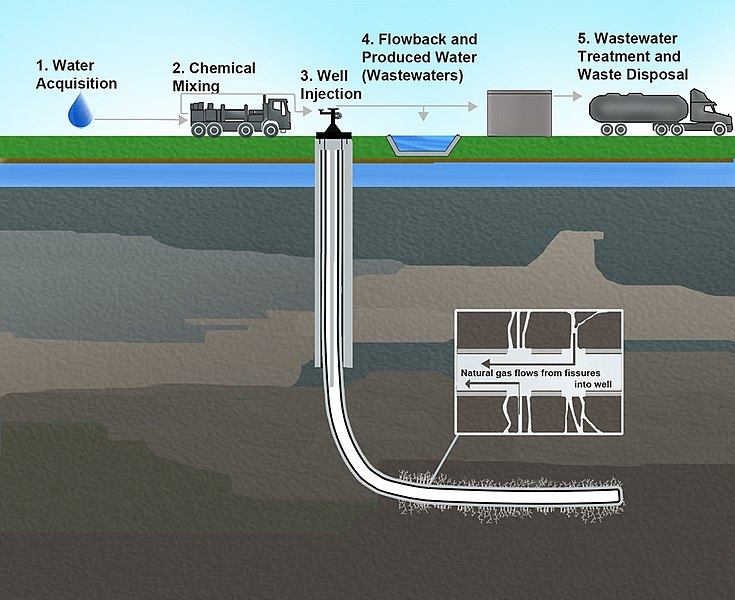

It is important to highlight that the fracturing referred to in this article is hydraulic fracturing, knowing that hydraulic fracturing is a technique applied to improve oil production in producing fields by injecting a fluid with multiple additives that is pumped under pressure into the field to improve the permeability of the formation.

The smart fracking technology is called SmartFleet and has been introduced by the Halliburton company, which is an automated system that controls hydraulic fracking activities to produce oil and gas.

What are the advantages of using this automated technique?

SmartFleet is a platform that combines benefits that make it different from any other platform nowadays, since it offers several contributions among which stand out:

It provides the operators performing the operation with a good control of the fracture in real time while pumping activities are performed.

Integration into soil fracture measurements.

Live 3D visualization and real time fracture commands.

How is this technology applied?

All SmartFleet equipment is connected to the oil producing reservoir with subsurface detection techniques, and with this it is possible to obtain continuous measurements of the reservoir's uniformity and geometry, where it is also possible to obtain measurements of the same level in the reservoir's lithological rocks.

The notable difference of this technique with the hydraulic fracturing is that in the hydraulic fracturing the fluid is pumped blindly, while with this technique operators can control the results of the fractures, they can also perform other actions in an automated way that helps a pumping and placement of the fracturing fluid in a location closer to the well and the distant field, as well as to directly manage the impacts of fractures, in conclusion with this technique you have greater control of the entire operation.

Conclusion and contributions

SmartFleet technology is a breakthrough in oilfield fracturing techniques and opens a much-needed path to smart fracture, which allows operators the ability to optimize fracture outcomes while simultaneously performing fracturing fluid pumping operations, thereby boosting capital efficiency and return on oil industry assets that are so scarce in these pandemic times.

This type of technology is excellent if you know how to take advantage of it, I would like to know if you have knowledge that this type of technology is already being used in Venezuela.

Hello my dear @lanzjoseg.

As far as the Venezuelan oil industry is concerned I do not think they are using this technology because here the drilling activities of wells are stopped and the improved recovery of crude oil here in Venezuela does not contemplate hydraulic fracturing in the producing formations, all this added to the fact that when drilling I never saw a technology of this type where there was a controlled drilling of this type.

I believe that this technology may be applied in other things such as GPS systems in cars and other systems, perhaps in the future when the oil industry recovers there are industries such as Halliburton, Schlumberger and Weatherford that bring not only this type of technology but all those that can minimize the time and costs in the exploration and production activities of hydrocarbons.

Greetings my dear friend and thank you for expressing your ideas in this valuable commentary.

Greetings friend @carlos84.

Another great contribution to the world of hydrocarbons, where one can find innumerable technological applications essential to the entire process of exploration and extraction of crude oil.

Thank you for continuing to provide us with excellent contributions in this field. Successes.

Thanks to you for commenting positively on this estimated post @rbalzan79. Greetings

hi dear @carlos84

I hope that this SmartFleet technology improves the performance of oil extraction, although I believe that little by little the oil will become obsolete, it is still appreciated that there are still advances in this industry

If technology has helped a lot in minimizing the costs and times of oil production, perhaps by the year 2500 oil will begin to show signs of depletion, there are still many undiscovered fields that extend the years of new oil reserves, unfortunately humanity has not yet succeeded in replacing oil completely, simply the alternatives of other energies help minimize production which is also good, but in my opinion there is still a long way to go.