In a producing well, a problem or problems may occur depending on the economics of a particular situation. It is the duty of the well analyst to identify the problems and offer solutions in order to have good production outcomes.

In this article, I will be discussing on a few well problems likely to be faced by the drillers and the rest of crew during the production of oil and/or gas from a well. As well as the possible solutions and remedial actions.

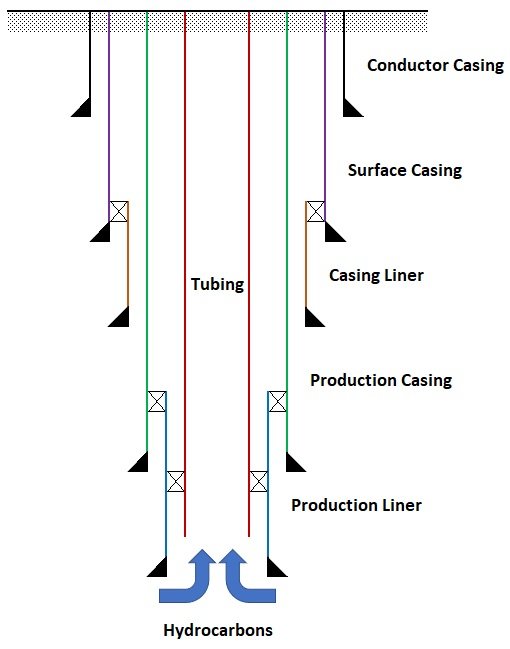

image source

Wellbore, Tubing and Perforations Plugging Problem

In the context of oil wells, a perforation refers to a hole punched in the casing or liner of an oil well to connect it to the reservoir. It can also be said to be the process of creating a channel between the pay zone and the wellbore to cause oil and gas to flow to the wellbore easily. Pay zone refers to the region where the oil is being accumulated; it's the target point of the drillers.

However, perforating a well it's demerits and the disadvantage is that perforating can lead to what is called skin damage, where debris from the perforations can hinder productivity of the well. Thus, the probability of tubing, wellbore and perforations should b carefully evaluated for all types of wells. Plugging is said to occur when the channels of flow of oil from the formation to the wellbore is being blocked. It may be caused by gravel pack or fracturing sand, perforating gun debris, tubing or casing, pipe dope, scales, asphalt, paraffin, formation rocks etc.

For flowing oil and gas wells, or injection wells, tubings should always be left open-ended so that wireline tools and production logging tools can be run to check for plugged tubings, wellbore or perforations. But if the tubing is not open-ended, it may be necessary to lower a wireline tool to check for the fill in the bottom of the the hole. Analysis of bottom hole samples are helpful in determining the cause of the plugging.

Wax deposition is a major problem in oil production as it blocks flow of oil. It is necessary that pluggings is being removed in a well if noticed else, production may decline. In order to remove pluggings or wax (paraffin) from tubings, wellbores and casings, solvent or hot water or oil is being employed. In fact, the best way to remove wax from the wellbore or formation is by squeezing an effective solvent into the formation.

High Viscosity Oil

The presence of heavy viscosity oil is another well problem that may hinder production. Heavy crude oil refer to highly-viscous oil that cannot easily flow to production wells under normal reservoir conditions. It is called "heavy" because its density or specific gravity is higher than that of light crude oil. Heavy crude oil has been defined as any liquid petroleum with an API gravity less than 20°.source

Note that high viscosity oil may be normal for a particular reservoir but if a reservoir is being produced by dissolved gas drive, as gas is released from the oil, its viscosity will be increased. Viscosities greater than 200 centipoise often caus serious flowing and pumping problems. If well producing problem are due to high viscosity water-in-oil emulsions in or near wellbore, it may be economical to either break or invert the emulsion with surfactants lower the viscosity of the produced fluid. Also, thermal stimulation may be applied in high viscosity oil reservoirs. However, this method is a good candidate solution for shallow wells and not economical for deep wells.

Excessive Back Pressure on Formation

Back pressure can be said to be the pressure within a system caused by fluid friction or an induced resistance to flow through the system. It is also the pressure opposing the desired flow of a fluid in a pipe during production and it usually results from obstructions and tight bends in confinement vessels, according to SLB

This back pressure is transferred upwards to the surface through the well casing and if not prevented can cause serious damages to the developed well and equipment. Excessive back pressure can highly lower the rate of production in wells producing from reservoirs nearing depletion. It may be due to limited or plugged perforations, partially plugged wellbore, tubing or flowline.

The remedies for excessive back pressure differ depending on the nature of the well in question. In oil reservoirs having appreciable loss of reservoir pressure, artificial lift in addition with reduction of separator, tubing or casing pressure will eliminate back pressure thereby restoring and increasing production. For high capacity wells, the usual approach is to increase the size of the tubing or flowline.

But if tubing, perforations and wellbore are partially plugged, removal of restriction by cleaning out will in production. However, reperforating is frequently the best approach to eliminating back pressure problems.

References

https://en.m.wikipedia.org/wiki/Perforation_(oil_well)

https://www.glossary.oilfield.slb.com/en/Terms/p/plug_and_abandon.aspx

https://www.petropedia.com/definition/307/back-pressure

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider supporting our funding proposal, approving our witness (@stem.witness) or delegating to the @stemsocial account (for some ROI).

Thanks for including @stemsocial as a beneficiary, which gives you stronger support. Using the STEMsocial app could yield even more supporti next time.