So it's almost there now, the soldering is done, jump rings for the chain are in place and now I've cleaned up all three pieces with pickle so they're just about ready to be polished and textured.

So in order to get the jump rings on what I had to do was use a pair of reverse tweesers, you place this onto the soldering brick and then that keeps the jump ring vertical without it falling over any time you try to solder it, once the solder is on properly then it won't budge.

Here you can see I've connected up the jump ring to the necklace correctly, next I had to do that for the other two as well, you may notice that there are gaps in the jump rings, they need to be soldered up so that the chain doesn't slip through or the jump ring gets moved apart by accident while being worn.

You should see in the second photograph how I've soldered together the gaps on the jump rings, that's now finished.

So with that done, now comes the part of cleaning everything up again.

It's still not shiny enough though for a silver piece! Next I will have to give it a proper polish, then we also need to look at adding on the berries finally once everything is does on the metal side of things.

As an added bonus, I mentioned briefly awhile back that I had some silver ingots that I had made awhile back, I bought an adjustable ingot mould out of curiosity and me and my teacher experimented with getting it to work. We found that realistically if you want this to work right, you need to get a steel funnel of some kind that can withstand the heat of molten metal. Why? Because what we found is that if you take too long pouring the molten metal in the metal cools down quickly while it's being poured and that ends up going solid at the very top of the mould rather than at the bottom so it would cause the molten metal to spill over.

This is why for instance as it turns out in those big smelters, refiners and so on they have those concrete chutes or some other form so that they can just dump all the metal in without having to worry. In case you're wondering how we got the funnel in the first place, we actually paid a metal fabricator next door to make one for us that could be pulled in half so the metal could be taken out after it had cooled. We had gotten the idea when looking at a youtube video when some other guy had somehow got an ingot mould that had it's own little chute for pouring.

I don't know where to get this kind of stuff generally, I know it's a long shot, but if anybody happens to know of a place where you can get proper funnels etc. made out of steel that would be great but it seems to be quite a specialised thing to ask for so we had to get it custom made. The reason I'm asking because it would be nice if at some point I could try doing this sort of thing on a bigger scale and the guy we paid is retired now. I don't even mind ordering them from overseas, because it's not like I'll be needing lots or anything, just as long as they're good quality.

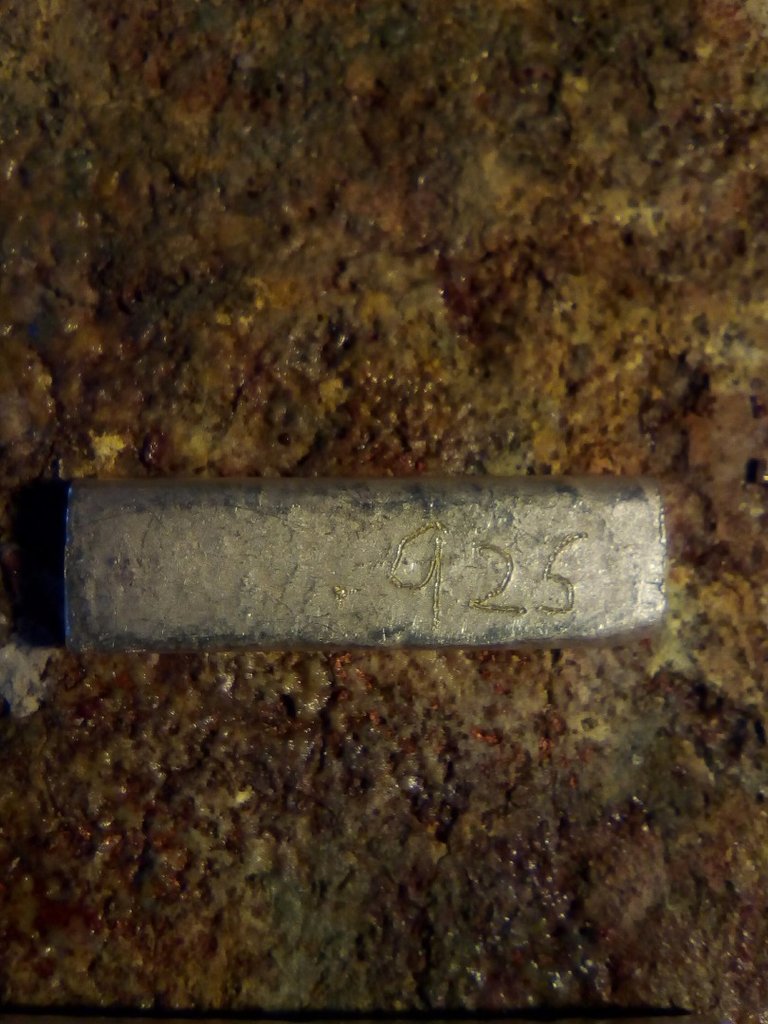

Cleaned up ingot that I even engraved slightly with the right metal percentage, .925 is sterling silver in case you were wondering, it's a very small ingot because it was melted down from cast offs and failed projects of mine so I can recycle my metal now.

thats cool