Ever felt like your day was full of little inefficiencies?

Maybe you walked across the house five times looking for your keys or printed 50 copies of a document when you only needed 10. Guess what? You’ve just experienced Lean waste and you’re not alone!

Lean Production Systems aren’t just for factories. They’re for anyone who wants to work smarter, not harder.

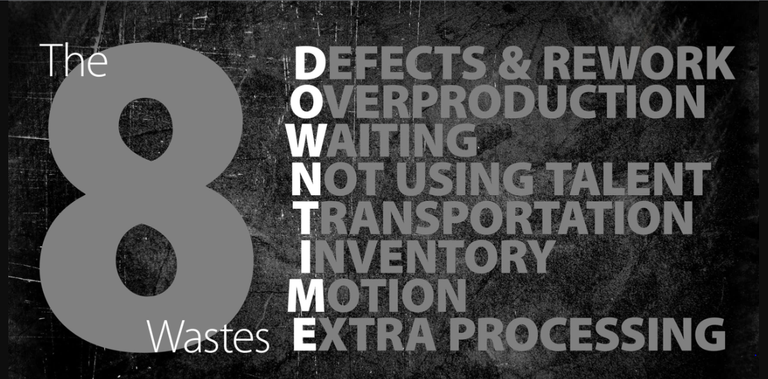

So, let’s dive into the 8 Wastes of Lean, with examples from both the shop floor and your daily life.

1. Defects – Oops, That’s Not Right!

Manufacturing: A car door gets painted the wrong color. Now it needs repainting — time, cost, frustration!

Real Life: Forgetting to set a timer and overcooking dinner !

Lesson: Mistakes cost time. Catch them early or prevent them altogether.

2. Overproduction – More Isn’t Always Better

Manufacturing: A bakery bakes 200 loaves when only 100 were ordered. The extras go stale.

Real Life: You cook a feast for 10, but only 4 people show up. Leftovers for days!

Lesson: Produce only what’s needed. Excess = waste.

3. Waiting – Hurry Up and Wait

Manufacturing: Workers stand idle while a textile machine gets repaired.

Real Life: You’re stuck waiting for your laptop to boot up or for your coffee to brew.

Lesson: Time lost in waiting is time you’ll never get back.

4. Non-Utilized Talent – Hidden Superpowers

Manufacturing: A skilled CNC operator is stuck doing basic packing.

Real Life: Your tech-savvy friend is asked to take notes instead of setting up the presentation.

Lesson: Use people’s strengths. Everyone has hidden talents!

5. Transportation – The Long Way Around

Manufacturing: Furniture parts are moved between distant warehouses unnecessarily.

Real Life: You drive across town for groceries that could’ve been delivered.

Lesson: Move only what’s needed, when it’s needed.

6. Inventory – Too Much of a Good Thing

Manufacturing: An electronics plant stockpiles raw materials far beyond forecast.

Real Life: You buy 10 bottles of shampoo on sale… and forget about them.

Lesson: Excess inventory ties up space, money, and energy.

7. Motion – The Daily Treasure Hunt

Manufacturing: Workers in a shipyard walk long distances to fetch tools.

Real Life: You spend 10 minutes every morning looking for your keys.

Lesson: Organize your space to reduce unnecessary movement.

8. Extra-Processing – Doing More Than Needed

Manufacturing: A metal part is polished twice when once would’ve been enough.

Real Life: You rewrite a simple message five times before sending it.

Lesson: Don’t overdo it. Focus on value, not perfection.

Final Thoughts

So next time you’re stuck waiting, overdoing, or searching for something — smile. You’re living Lean, and you’re learning to do better.

Lean isn’t just a factory philosophy — it’s a life skill. Once you start spotting these wastes, you’ll find ways to improve everything from your morning routine to your team’s workflow.