These modules are in charge of the intercommunication work between the industrial devices outside the PLC and all the low-power electronic circuits that comprise the central processing unit of the PLC, which is where the control program is stored and executed.

The input and output modules have the mission of protecting and isolating the control stage, which is mainly made up of the PLC microcontroller, from all elements outside the central processing unit, whether sensors or actuators. The input and output modules act as interface devices, which among their main tasks are to adapt the electrical levels of both sensors and actuators or power elements, to the voltage values used by the microcontroller that is normally based on levels of TTL logic, 0 VCD equals a "logical 0", while 5 VCD equals a "logical 1".

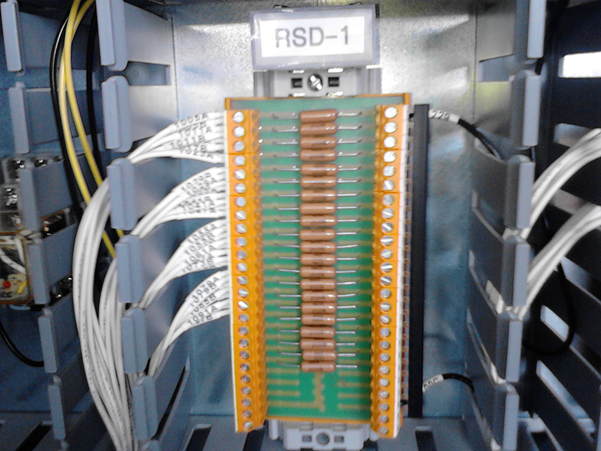

Physically, the data input and output modules are built on printed circuit boards that contain the electronic devices capable of isolating the PLC with the external environment, in addition to having light indicators that visually inform the status of the inputs and outputs.

In order for the input or output modules to carry out the task of electrically isolating the microcontroller, it is required that the microcontroller does not have physical contact with the connection terminals of either the sensors or actuators, with the connection lines that reach the input or output ports of the microcontroller.

The isolation function lies basically in the use of an optoelectronic element also known as optocoupler, through which the physical contact of the connection lines that are present in the circuitry is avoided, the optoelectronic device is constituted in the following way. Internally within an encapsulation there is a light emitting diode (LED) that generates an infrared light beam, and as a complement also next to the infrared led is a phototransistor. When the infrared led is directly polarized between its terminals, it emits an infrared light beam that reaches the base terminal of the phototransistor, which once the base terminal is excited causes the phototransistor to enter a conduction state, generating an electric current between its emitter and collector terminals, manifesting an operation similar to a closed switch. On the other hand, if the infrared led is polarized in an inverse way, the infrared light beam is extinguished, causing at the same time that if in the base end of the phototransistor does not receive this light beam, no electric current is generated between its emitter and collector terminals, showing an operation similar to an open switch.

Since the infrared light beam is the only contact between a power stage or sensor reading with the control stage, there is a perfect means of isolation that is also very safe and do not lose the controls that activate the actuators or the signals that generated the sensors.

The direction in the data flow of the modules depends on whether they are input or output, what is common between input and output modules are the terminals where they are physically connected either sensors or actuators, the number of terminals that a module can have depends on the PLC model as there are commercially modules of 8, 16 or 32 terminals. In the connection terminals of these input or output modules are connected the signals generated by sensors or those that manipulate the actuators, which have the mission to monitor and manipulate the process that is automated with the PLC.

There are different input and output data modules, the main difference depends on the different types of signals they handle, this means that there are modules that handle discrete or digital signals, and modules that handle analog signals.

The signals generated by the sensors are sent to the data input modules. Taking into account the variety of sensors that can be used in an industrial control process, there are two types of input modules which are described below.

Discrete Data Input Modules - These respond to only two different values of a signal that can be generated by the sensor. The signals can be the following:

a) The sensor manifests a certain amount of energy different from zero if it detects something.

b) No energy if there is no detection of something.

An example of a sensor used in this type of module is the one used to detect the end of stroke of a piston rod.

For this type of discrete input modules, in one of its terminals one of the terminals of the sensors has to be connected in a common way, for it we have to locate which is the common terminal of the input modules.

Analog data input modules - Another type of input module is the one that contains in its circuitry an analogical-digital converter (ADC), so that depending on the sensor connected, it interprets the different magnitudes of the physical variable that is being measured and digitizes them, so that later these data are transported to the PLC microcontroller. An example of a sensor used with this type of module is the one that measures temperature.

his concludes another installment that I leave for you with much affection hoping that I can be of use to you and sincerely thanking you for the time you have taken to read my article.

All images used in this article are my own, photographs taken during my professional work. I allow the use of these images as long as they are mentioned to me in the article and the source is cited.

Steemit is expanding to other blog ecosystems, will soon be official with Smart Media Tokens and is already possible for WordPress thanks to the steempress plugin, a revolutionary initiative. If you wish to support the project I invite you to vote for @steempress as a witness by clicking here

Posted from my blog with SteemPress : https://automation80.000webhostapp.com/2018/09/plc-data-input-and-output-modules

Congratulations @automation80! You have completed the following achievement on the Steem blockchain and have been rewarded with new badge(s) :

Click on the badge to view your Board of Honor.

If you no longer want to receive notifications, reply to this comment with the word

STOPDo not miss the last post from @steemitboard: