Each sensor will take influence on an actuator by means of an instrument programmed to respond to input signals that can be of the analogical or discrete type, it is true that I mentioned previously on the controllers but from this point we begin to deepen on them from the industrial point of view. I have taken the subject of industrial automation as a starting point because it is where we find robust equipment whose operation is widespread and manufacturers of industrial equipment dedicated to automation are careful because their products are easy to use by trained personnel, the less complex is the more attractive device is in the market. Today I want to explain one of the oldest controllers, the pneumatic controller which, because it is not so old, is no longer used at all.

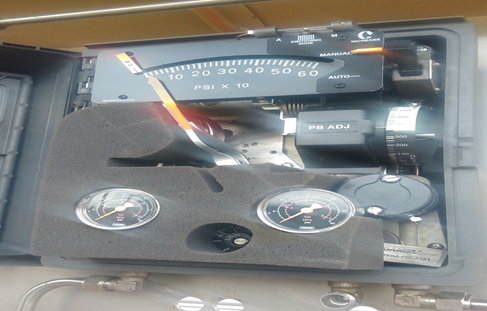

These equipments act under mechanical principles but using pneumatic energy to control the process, the sensor element is inside the same equipment and must receive a pneumatic signal coming from the point where you want to adjust the variable, it must be configured by means of the available adjustment points for speed, set point and types of control. Once calibrated these devices will have an output pressure (to move an actuator) that will depend on the input pressure to it (from the measuring point), through an actuator will try to modify the input signal to obtain the desired value.

One of the main advantages of these equipments is that they use pneumatic energy which is easy to produce, it can be compressed air or gas which is taken from the same process.

One of the most used applications is in the gas treatment process, assuming the role of an element for the control of the regulation in case of failures of the electrical system. In the image we can appreciate the equipment in the background, the green valves located in pairs are one controlled by electronic equipment and another by this pneumatic controller, the measurement point is taken upstream of the valve and in response to this measurement the controller sends a signal to the control valve which will open or close according to the needs of the process to bring the variable (pressure) to the desired point. This process is known as regulation because when there is a change in the variable you want to keep at a specific point this controller responds by sending a signal to the valve to act on that purpose.

But the use of these devices is limited to the creativity of the engineer as many things can be done with them. There are also specific designs destined to the control of another type of variable such as the one on the right who controls the variable level. The sensor element is a mechanism of balanced balances in which the float submerged in the liquid determines when the controller is activated, the action of the controller will be to send a signal to a valve that will allow to drain the liquids or act on the variable level as the process requires it. The balance consists of the force of the spring which can be adjusted by turning the corresponding points and the weight of the float which varies according to the level of liquid in the container. When the float exerts less force than the spring because it rises with the help of the liquid present, a pneumatic relay is activated that allows the passage of air to the actuating valve.

This concludes another installment that I leave for you with much affection hoping that I can be of use to you and sincerely thanking you for the time you have taken to read my article.

All images used in this article are my own, photographs taken during my professional work. I allow the use of these images as long as they are mentioned to me in the article and the source is cited.

Steemit is expanding to other blog ecosystems, will soon be official with Smart Media Tokens and is already possible for WordPress thanks to the steempress plugin, a revolutionary initiative. If you wish to support the project I invite you to vote for @steempress as a witness by clicking here

Posted from my blog with SteemPress : https://automation80.000webhostapp.com/2018/09/pneumatic-controller