If you dont know by the title whats this post will be about, additive manufacturing is also known as 3D printing for which I assume most have heard of.

It is process of adding layer on top of another layer, from there it got name additive, materials used there are mostly polymers, metals and concrete. The process was developed in the 1980s but because of patent wasn't widely used until 2000s and 2010 where it becomes widely popular among enthusiast and manufacturing companies.

The applications are limitless from sports goods, medical, part of cars, turbines, seats, mobile phone chases even whole houses and bridges. Its has been used mostly for visualization before manufacturing or in rapid prototyping stage where you can actually see and „feel“ the product check if there is any functional or design flaws, for small scale production, production of very precise and small parts.

So lets say that you have some idea in your head that you would like to make, first step would probably be to write or sketch that idea on paper in order not to forget it ( of course you can skip this step ) next one is to create a 3D model of idea and decide from what material you want it to be produced. Then it comes to on what machine and what technique will be used. After all that its only push of a button left to start production and eventually cleaning the part if its necessary.

Main advantage is that you can create any shape and form you can imagine, and with that caricaturist your product with right optimization should get lighter and stronger, because of structural optimization there is less material being used and that means less material and energy costs, by some calculations that numbers could get 50 up to 80% difference compared to traditional manufacturing.

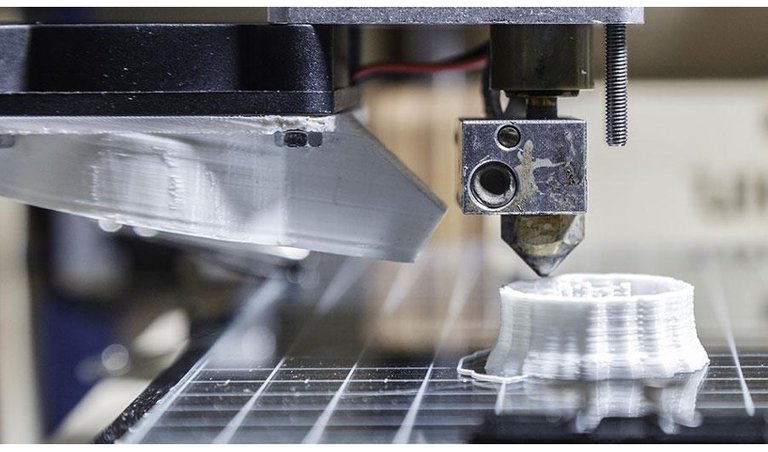

There are many different methods in 3D printing here are some of mostly used. FDM uses thermoplastic materials delivered through the nozzle which is heated. Head of printer with nozzle is being moved with usually stepper motors and following path set by computer program for each layer. Process repeats until whole code is finished and we should have completed part identical to our 3D model ( eventually scaled ), there are variety materials that can be used for different part functions, mostly used are PLA, ABS, HIPS, flex and elastic materials also different colors.

SLA uses resin that uses light for curing, the part is being made in pool of resin and its being risen with each layer. It has better overall quality compered to FDM but its also more expensive one.

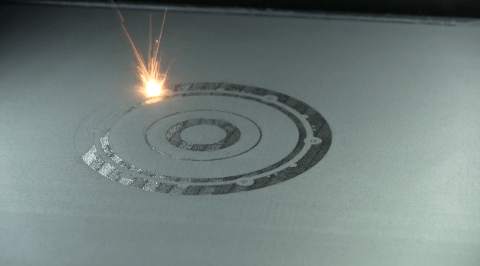

SLS uses laser to fuse small particles of materials, usually used with metal, ceramic, glass and plastic.

Process is made with fine powder and laser melting it in each layer after which bed is lowered and another layer of powder is applied and again fused with laser and that repeats for the whole part.

I would highly agree with that statement, it is highly being used by large company and has a lot of benefits in weight, material and cost reduction but its currently limited with range of materials it cant manufacture all metals and alloys but it is fast developing technique and it also could be blend together with metal casting and machining. For example we could make representative part from plastic material and made it with 3D printing after which it can be used ad a mold part to create mold shell around it for investment casting after mold is made our printed part can be melted to create hollow part for metal casting. With approach like that we have combined two of technologies and get part which we couldn't get with each technologies separate, for 3D printing its hard to use Magnesium as main material and for metal casting its hard to produce shapes lake that without 3D printing.

Great post!

Thanks :)

@kanu1988

Great post! I'm working at a start-up company which does additive manufacturing with a TruPrint1000 SLM maschine. If youre interested in this topics you could follow me. My future posts will contain content about additive manufacturing metal parts. Thanks a lot and greetings from Switzerland