source: panoramio.com

source: panoramio.com

Irrigation canals are the main waterways that bring irrigation water from a water source to the areas to be irrigated. They can be lined with concrete, brick, stone, or a flexible membrane to prevent seepage and erosion.

An open canal, channel, or ditch, is an open waterway whose purpose is to carry water from one place to another. Channels and canals refer to main waterways supplying water to one or more farms. Field ditches have smaller dimensions and convey water from the farm entrance to the irrigated fields.

Types of Canals lining

There are varieties of linings that are available today but we will be discussing the following three:

✓Plain Cement Concrete Lining

✓Reinforced Cement Concrete Lining

✓Brick Lining

1. Plain Cement Concrete Lining

This lining is recommended for the canal in full banking. The cement concrete lining is widely accepted. It can resist the effect of scouring and erosion very efficiently. The velocity of flow may be kept above 2.5 m/s. It can eliminate completely growth of weeds. The lining is done by the following steps:

(a) Preparation of sub-grade

The sub grade is prepared by ramming the surface properly with a layer of sand (about 15 cm). Then slurry of cement and sand (1:3) is spread uniformly over the prepared bed.

(b) Laying of concrete

The cement concrete of grade M15 is spread uniformly according to the desired thickness, (generally the thickness varies from 100mm to 150 mm). After laying, the concrete is tapped gently until the slurry comes on the top. The curing is done for two weeks. As the concrete is liable to get damaged by the change of temperature, the expansion joints are provided at appropriate places.

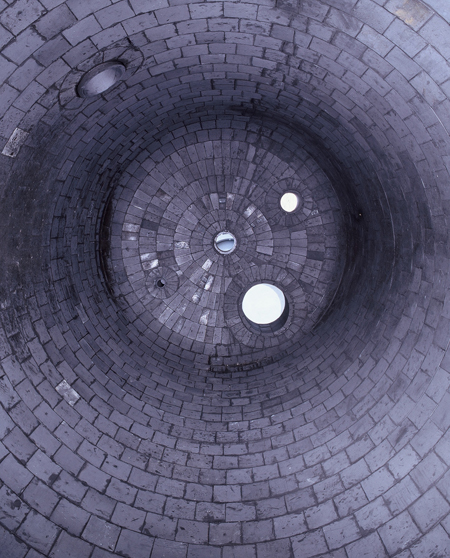

2. Brick Lining

This lining is prepared by the double layer brick flat soling laid with cement mortar (1:6) over the compacted sub-grade. The first class bricks should be recommended for the work. The surface of the lining is finished with cement plaster (1:3). The curing should be done perfectly.

This lining is always preferred for the following reasons:

• This lining is economical.

• Work can be done very quickly.

• Expansion joints are not required.

• Repair works can be done easily.

Bricks can be manufactured from the excavated earth near the site. However this lining has certain disadvantages:

• It is not completely impervious.

• It has low resistance against erosion.

• It is not so much durable.

3. Reinforced Cement Concrete Lining

Sometimes reinforcement is required to increase the resistance against cracks and shrinkage cracks. The reduction in the cracks results in less seepage losses. However this reinforcement does not increase the structural strength of the lining. This reinforcement adds 10 to 15 percent to the cost and for this reason steel reinforcement is usually omitted except for very particular situations.

Factors Affecting Type of Canal Lining

Imperviousness of Canal Lining

When the canal passes through the sandy soil the seepage loss is at maximum and the canal is unstable.

So, to make the canal perfectly impervious and reasonably stable, the most impervious types of linings should be recommended such as cement concrete etc.

Smoothness of Canal Lining

The smoothness of the canal bed and sides increases the velocity of flow which further increases the discharge of the canal. Due to the increased discharge, the duty of water will be more. So, to increase the duty, the canal surface should be made smooth. The lining like cement concrete, pre-cast cement concrete etc gives smooth surface to the canal.

Durability of Canal Lining

The ultimate benefit of any project depends on the durability of the hydraulic structures, canals, etc.

So, to make the canal section more durable against all adverse effects like scouring, erosion, weather action, etc. the most strong and impervious types of lining should be recommended.

Economy of Canal Lining

The lining should be economically viable with the benefits that may be accrued from the expected revenue, yield of crop, etc.

So, by studying the overall benefits the type of lining should be recommended.

Site Condition

Another Factor Affecting Type of Canal Lining is the site condition. The canal may pass through the marshy land, loose sandy soil, alluvial soil, black clayey soil, hard soil, etc. So, according to the soil and site condition the type of lining should be recommended.

Life of Project

Every project should be designed to serve the future three or four decades successfully. The type of lining should be recommended keeping in mind the life of the project.

Availability of Construction Materials

The expenditure of lining depends on the availability of construction materials, carriage charges, etc. To reduce the expenditure of lining, the materials which are available in the vicinity of the project should be utilized.

Advantages and Disadvantages of Canal Lining

Advantages of Canal Lining

• It reduces the loss of water due to seepage and hence the duty is enhanced.

• It controls the water logging and hence the bad effects of water-logging are eliminated.

• It provides smooth surface and hence the velocity of flow can be increased.

• Due to the increased velocity the discharge capacity of a canal is also increased.

• Due to the increased velocity, the evaporation loss also can be reduced.

• It eliminates the effect of scouring in the canal bed

• The increased velocity eliminates the possibility of silting in the canal bed.

• It controls the growth of weeds along the canal sides and bed.

• It provides the stable section of the canal.

• It reduces the requirements of land width for the canal, because smaller section of the canal can be used to produce

greater discharge.

• It prevents the sub-soil salt to come in contact with the canal water. 12. It reduces the maintenance cost for the canals.

Disadvantages of Canal Lining

• The initial cost of the canal lining is very high. So, it makes the project very expensive with respect to the output.

• It involves many difficulties for repairing the damaged section of lining.

• It takes too much time to complete the project work.

• It becomes difficult, if the outlets are required to be shifted or new outlets are required to be provided, because the dismantling of the lined section is difficult.

Source: aboutcivil.com

Hi! I am a robot. I just upvoted you! I found similar content that readers might be interested in:

https://www.aboutcivil.org/factors-affecting-type-canal-lining