Good day steemians! Today I will be sharing you my experience in soldering copper tube by using a blow torch.

As a mechanical engineering student, we use machine shop for our practice and to experience what the outside world feels like. In this way we can actually get a snippet of how real jobs we will be in the future that was not taught in lectures. And for today, we practiced soldering a copper tube.

Last Tuesday, March 13, 2018 our instructor introduced us the different materials and tools needed to perform our first hands-on activity for the subject Airconditioning & Refrigeration. Almost all of us are beginners in handling the tools needed which makes it a little exciting.

Now I will be talking about the tools that we used.

BLOW TORCH

Image Source

COPPER TUBE

Image Source

COUPLING

Image Source

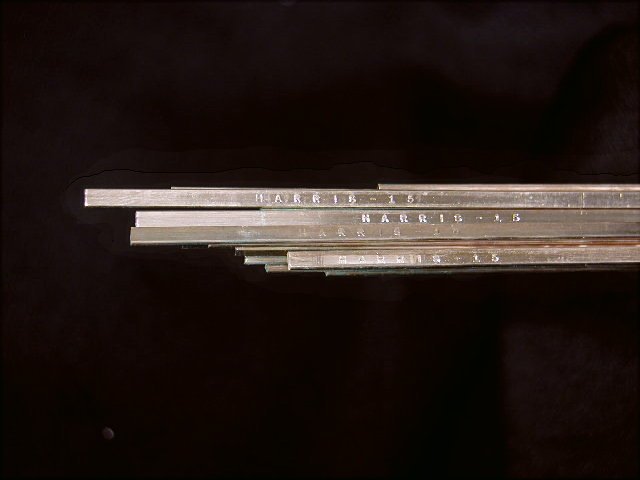

SILVER ROD

Image Source

The first try was a little hard for this is also my first time in performing this activity. After the session I now realize how to solder copper tube perfectly. These are the steps upon performing:

- Turn on the blow torch and adjust the flame depending on how you will comfortably use it.

- Focus your flame to the copper tube with inserted coupling where you need to solder.

- Heat the copper tube and the coupling together with the silver rod until it turns reddish.

- Try to link the coupling and copper tube with the silver rod, if it sticks then that may mean the other one is a little colder than the other so continue on heating.

- When it is properly heated, make sure to completely fill the copper tube-coupling joint by running the solder tip around the seam.

That is all the steps you will future perfect with practice! Here are the pictures of my classmates during the activity.

and to our professor on the left sir Sotomayor!

Hello! @mildredamit @jumargachomiano @josealmergepegs @earllfortuna

All in all, it was a fun experience! The result was a success for we tested it with air pressure and in the end it was proved that there were no leaks. I hope to improve the technique if I am already on the field where other engineers are expert in this kind and many more.

That's a wrap! Thank you and hope you like it!

Yours,

@jasoncaspe

Teenvestors Cebu (Road to Financial Freedom Channel). This service is exclusive to Steemians following the Steemph.cebu trail at Steemauto. Thank you for following Steemph.cebu curation trail!Congratulations! This post has been upvoted by the communal account, @steemph.cebu by jasoncaspe being run at

Don't forget to join Steem PH Discord Server, our Discord Server for Philippines.