Modern Manufacturing: Conformation process for plastics through an injection molding cycle

Fraternal I greet the entire Stemmit community. It's a pleasure to post them again

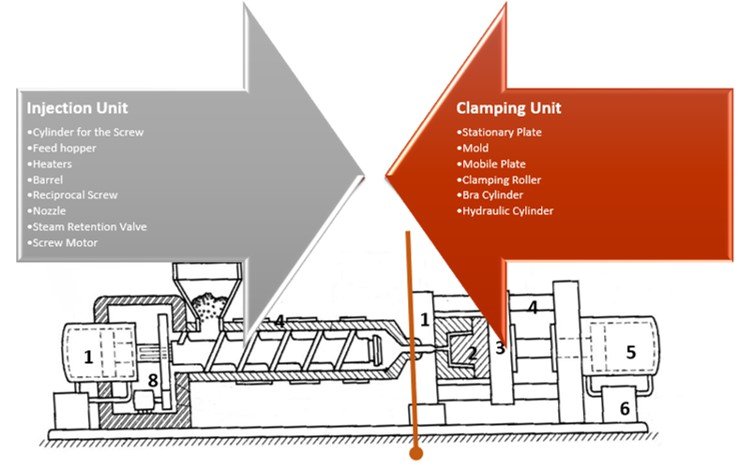

From the technical and operational point of view; the conforming for plastics through the equipment with injection molding cycle is mainly defined as a process in which a polymer is heated until it reaches a very plastic state and it is forced to flow at high pressure towards the cavity of a mold; where it solidifies. Then, the molded part, called molding, is removed from the cavity. It needs to be developed according to two main aspects: Injection Unit and Clamping Unit or Clamps.

This cycle of injection molding a thermoplastic polymer consists of the following sequence:

- The mold is closed and fastened

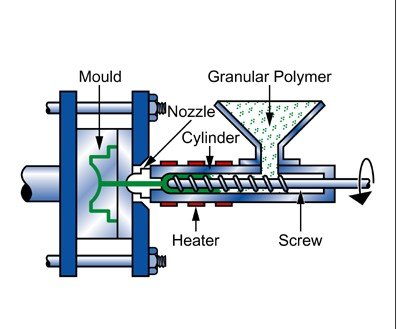

- A high pressure melt shot is injected into the mold cavity, which has been set to the correct temperature by means of heat and mechanical work of the screw. The plastic cools and begins to solidify when it meets the cold surface of the mold. The pressure of the ram is maintained in order to compress more melt in the cavity to compensate for shrinkage during cooling.

- The screw rotates and retracts with the steam check valve open to allow the new polymer to flow towards the front of the barrel. Meanwhile, the polymer in the mold has completely solidified.

- The mold is opened, and the piece is ejected and removed. It is related to the operation of the mold.

The Injection Unit is very similar to an extruder. It consists of a barrel that is fed from one end by a hopper that contains a supply of plastic pellets. Inside the barrel there is a screw whose operation exceeds that of the extruder screw since in addition to turning to mix and heat the polymer also acts as a type of screwdriver that moves quickly forward to inject molten plastic into the mold. A non-return valve mounted near the tip of the screw prevents the melt from flowing backwards along the cords of the former. At a later stage of the molding cycle, the ram returns to its original position. In summary, the functions of the injection unit are to melt and homogenize the polymer and then inject it into the mold cavity.

For its part, the clamping unit is related to the operation of the mold. Its functions are derived in three main aspects:

- Keep the two halves of the mold aligned correctly

- Keep the mold closed during the injection by means of the application of a force that holds it sufficiently to resist the injection force.

- Open and Close the mold at the appropriate moments of the injection cycle.

The clamping unit consists of two plates, one fixed and another mobile and a mechanism to move it. The mechanism is basically a power press that works by means of a hydraulic piston or mechanical lever devices of various types.

Additionally, the mold is the special tool in injection molding. It is custom designed and manufactured for the specific part that is to be produced. When the production run of that piece ends, the mold is replaced by another one for the next piece. It is worth noting that, for the materialization and specification of each mold, special design programs are required, such as the AUTOCAD, which allows to accurately include measurements and movements required for the finished product. All this, together with its manufacture in companies of services contracted for the machining and manufacture of steel molds and similar alloys.

It is also required for the mold, an ejection system to eject the molded part of the cavity at the end of the molding cycle and a cooling system composed of an external pump connected to passages in the mold, through which water circulates to remove heat from the hot plastic.

In order to develop with the utmost possible efficiency an event that encloses the project for the effective injection molding of pieces with High Density Polyethylene it is necessary to take into consideration a series of parameters:

MASS

For the manufacture of any product is based on the principle that states that the mass can only undergo transformations in the universe but neither created nor destroyed. That is to say, in the present scope it applies in the interpretation for the materialization of goods generated from the same amount of raw material that is added.

For each injection molding cycle machine 482 gr / 1.06 Lbs is required. of High Density Polyethylene (HDPE) to manufacture, for example, a standard safety helmet. There is the possibility that for defects in the design of the mold with too large ducts, very high pressures with respect to the clamping force, excessively high temperatures and irregular injection sizes will generate burrs or slags of plastics in the molded part, generating with This is a loss of material and defect in the helmet. In this sense, a margin of 2% of material slack is considered.

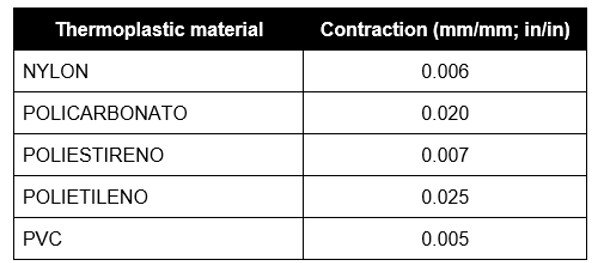

CONTRACTION

The phenomenon that thermoplastic polymers suffer from reducing their volume during their cooling in the mold is called with such a term. There is even the case of reduction by volumetric shrinkage of up to 10% after injection in the mold, depending on the material. It is very important to know the contraction value according to the specific compound that will be molded to optimize the specifications in the dimensions of the mold machining and thereby obtain better results in the final piece.

It is worth noting that each value of contraction in different components depends exponentially on the density or mass ratio in volume and physicochemical properties that each one possesses. A reference commercial compilation is as follows:

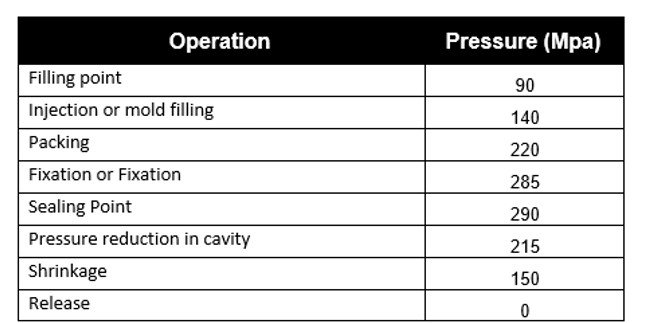

PRESSURE / STRENGTH RELATIONSHIP

According to this extremely important parameter in the operations, the tonnage or the installed capacity that is required by a machine to manufacture the final piece is established; in this case, a safety helmet of High Density Polyethylene with the dimensions already mentioned. Commercially, there are machines from 10 Ton and 4,400 Ton that proportionally have a higher force capacity to withstand pressures in the cycle clamping unit.

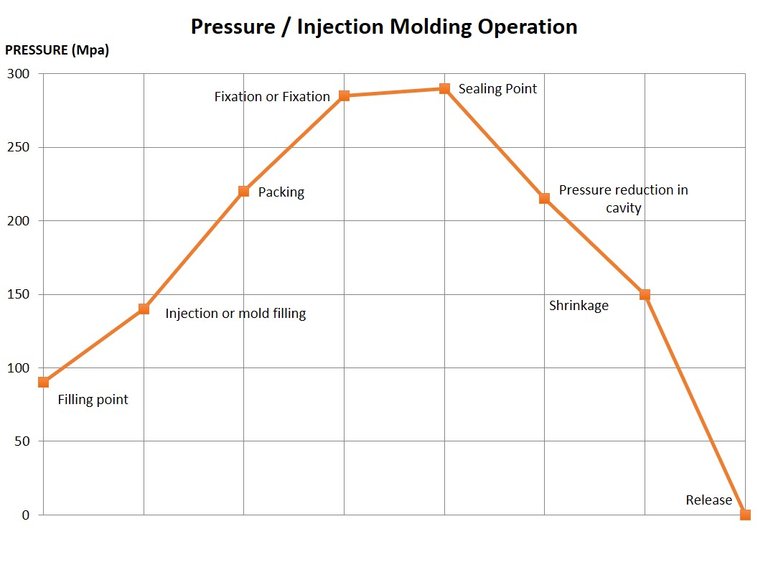

In this case, machines that exceed 1,000 Ton are required; because 1.06 Lbs of material injected into each mold are needed with dimensions that on average exceed 9.5 in. with pressures of up to 290 Mpa. In this order of ideas, according to each of the phases that comprise the process, different pressure patterns are exerted fundamentally inside the mold by the clamping unit after the injection and generated by the resistance exerted by the flow to flow with the high viscosities of the thermoplastics when reaching the desired temperatures through the circulation diameters in the injection cavity and the mold.

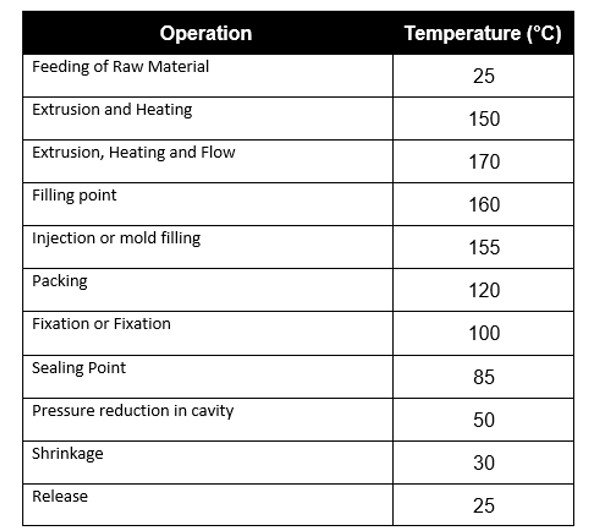

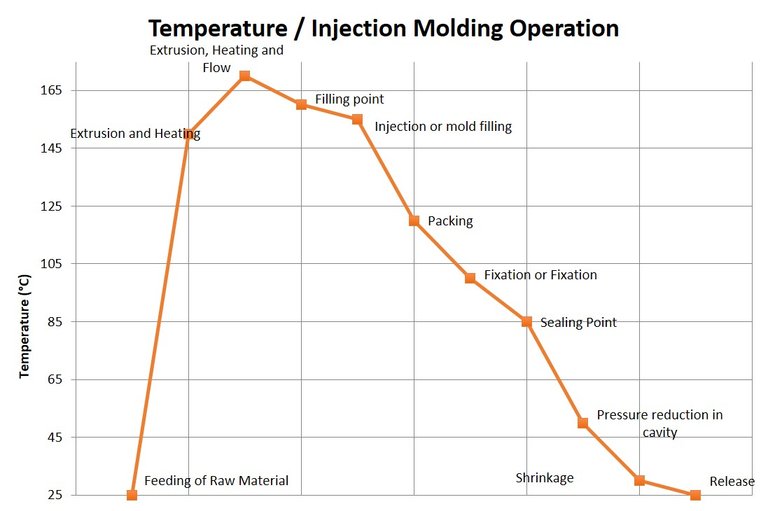

TEMPERATURE

It is possibly the most important parameter in the effectiveness of the operation with satisfactory results. It is not a constant value, and can be regulated by the machine depending on the raw material you want to work with. Each thermoplastic polymer varies in its temperatures according to the specifications of the supplier (according to molecular weight, polymer branching, polydispersity, thermal conductivity, thermodynamic properties and additives) and should suggest such variations with respect to properties such as flow index and working temperatures .

In any case, the procedure suggests interpreting in each thermoplastic material the temperature required to reach the melting point that reduces its properties of hardness, rigidity, elongation percentage and density while stabilizing its viscosity to a point that allows the fluidity by means of the cavity of the injection nozzle and up to the cavities of the mold. Basically, different melting temperatures are known in each of the thermoplastic polymers.

It is worth noting that the drop in temperature after the injection of the thermoplastic flow is due to the cooling system in the mold of the machine with the passage of air and water in cavities and narrow passages in the separation surface with 0.001 in. of depth and from 0.5 to 1 in of width approximately; avoiding with that dimension by the viscosity of the material that the polymer flows through them and that the ideal conditions are obtained with the cooling of hardness, rigidity and density.

I hope all this information is useful and you have liked my contribution. For more information consult the following sources:

https://www.creativemechanisms.com/blog/everything-you-need-to-know-about-injection-molding

http://www.custompartnet.com/wu/InjectionMolding

https://www.xcentricmold.com/about-injection-molding.php