Hello everyone and welcome back to our fifth "LHSM". Before starting I have to explain some choices that are never been adequately explained in the previous articles.

- Birraiooo but why do you only talk about Diesel engines?

Well actually the answer is simple, the four-stroke Diesel engine has undergone considerable improvements during its lifetime, and the technological implementation has brought excellent achievements, especially considering the semi-electronic or full electronic control engines, but the substance does not change . The Diesel engine is always the same, whether it is a 1200cc mounted on a panda or a 50,000cc mounted on a ship, the engine is always the same. Bigger, but equal. Needless to say, it is a perfect subject for a more in-depth study, because it offers less "facets" to deal with.

- What does "LHSM" mean?

"Let's have some mechanic". As a mechanic, my imagination is limited to what I see, and I saw an "L", an "H", an "S" and an "M". Easy.

- What are we talking about today ???

Today we talk about:

The cooling system

Well, of course, we had to arrive early or late. Since the subject is completely separate from the previous articles, it can easily be read without reading the mechanics of the movement we had seen in the first four articles.

Why do you need a cooling system? First we take into account that we have mechanical elements, which lubricated with oil, move on each other, and with all the necessary precautions, however, they create a minimum friction that generates heat, but this is the least.

In the expansion chamber, diesel and air generate explosions ... and the explosions are hot.

The combustion temperature exceeds without problems the 230/300 ° C in a single cycle, of a single piston. At full engine speed, a large engine can maintain an exhaust gas temperature of up to 400 ° C depending on the calibration.

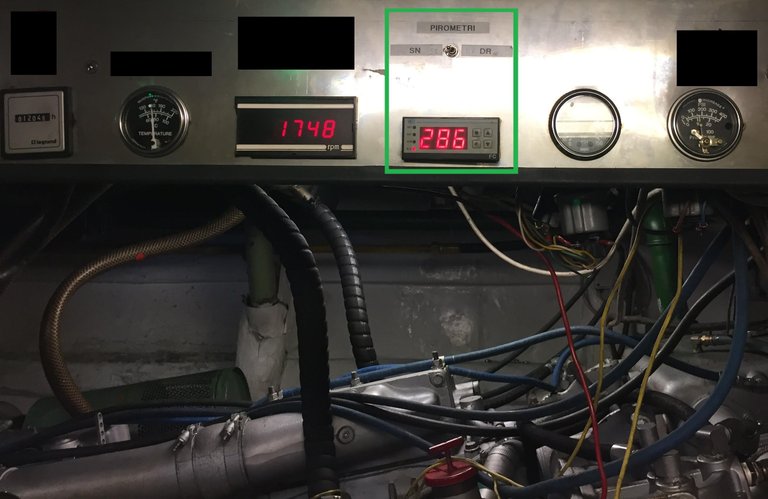

Author's photo

(all references that may allow identification of the vehicle have been censored)

In the picture you can see a test I performed on an engine, which had some slight discomfort to the left turbine. the central number identifies the degrees in Celsius of the exhaust gases, measured by means of a "Pyrometer" (a thermometer with very high flow rates) placed immediately after the turbine, its use is useful to monitor any abnormal behavior by the engine, if the values do not fall within the specifications declared by the manufacturer, the technicians will be able to operate for the necessary repairs.

Detroit Diesel Engine 12V92 - 2 cycle Calibration from 600Bhp

So we have extremely high temperatures, and these temperatures must be lowered, otherwise the risk is to found with some pieces of molten metal scattered around the workshop, taking care, however, to remember that the purpose of the cooling system, is also to "maintain optimal operating temperature".

Usually for diesel engines, the ideal operating temperatures remain, depending on the engine, between 75 ° and 95 ° C.

The elements:

To create a good cooling system, we need the following elements:

- A water containment box with its cap;

- A water pump;

- A water heat exchanger (or a radiator if is more familiar);

- Thermostatic valves;

Let's see them in detail.

The water tank and the cap:

The water tank does not have to do anything but contain the coolant, this box is connected to the whole engine both in suction and delivery, but the really interesting part is the cap for closing. each cap has a spring, which allows the pressure to be maintained inside the engine cooling system. The pressure must be maintained to avoid evaporation, and therefore the boiling of the water itself."The pressure of a gas of fixed mass and fixed volume is directly proportional to the gas's absolute temperature."

The water pump

Water pump with flexible impeller

Image under CC0 license

- To the engine block for cylinder cooling;

- At the cylinder head, for the cooling of all its components;

- If necessary, to the turbine and to the exhaust manifold *

At the end of the lap induced by the pump to cool all the parts listed above, the pump will direct the hot water towards a heat exchanger.

*not all engines cool the components intended to convey the exhaust gases

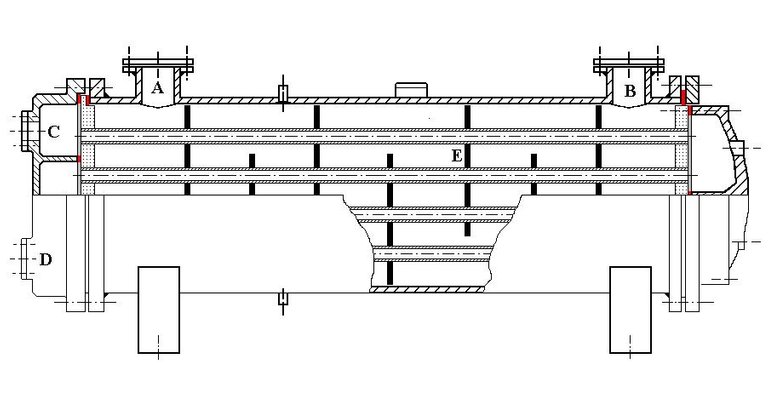

The Water heat exchanger

After the lap for the "hot parts" of the engine, the water, due to the heat exchange, cools the components, but also acquires heat, and now, we need to cool it again, to do that we need a heat exchanger, or a radiator, these objects, exploit a cold element to recreate a new heat exchange, allowing the water to release heat and cool itself.

In cars, it is common to find the air-cooled radiator.

hot water circulates through small pipes, which are cooled by the air generated by the car itself during the normal forward motion, which, conveyed through the fins on the nose of your car, is pushed directly on the radiator.

If the car is stationary, and the temperatures begin to no longer be contained, the radiator is equipped with an electronic fan, which will cool the water

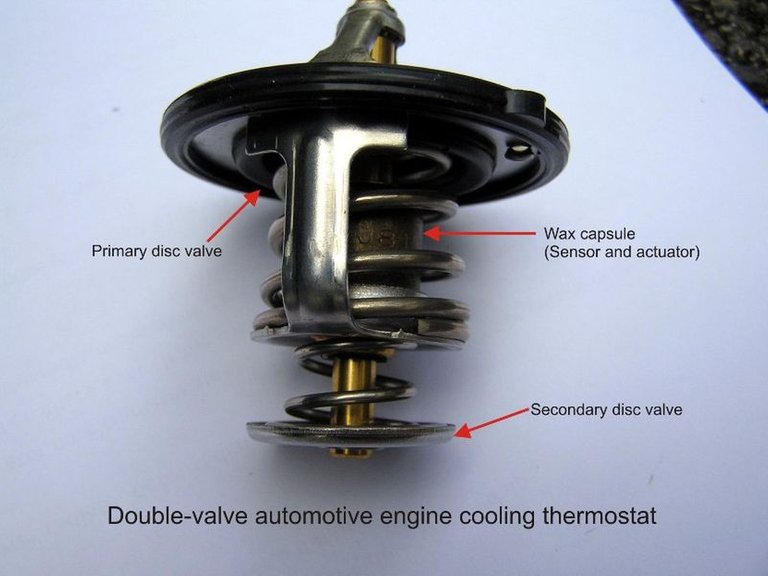

Thermostatic valves

Not least in importance, the thermostatic valves, mainly serve to maintain the stable engine temperature by diverting the water course directly to the radiator, and allowing only in some moments, to cool a portion of liquid "ahead of time". The central bulb, in the photo called "Wax capsule", contains inside a wax, or an oil, which, when reaching a certain temperature, expands, opening the "Primary disc valve" and thus allowing the passage of water to the radiator. When the temperature is lowered again, the liquid contained in the bulb of the thermostatic valve will cause it to close again, thus preventing the passage, and thus raising temperatures again. This procedure allows the motor to always maintain constant operating temperatures with thermal changes of up to 1-2 ° C.And That's all

The cooling system ends here, and in case you're wondering, no I did not forget the oil cooler, it's just that we'll talk about it later, when we do the lubrication circuit.

Always remember, when in your car the light of the water temperature comes on, listen to me, the problem is almost certainly in one of these elements that I have just illustrated ... Unless you have demolished the cylinder head .. in that case, change machine.

A big hug, and thank you for coming here!

Although my sources are based entirely on my experience, here you can find some confirmation of what is written above.

Immagine CC0 Creative Commons, si ringrazia @mrazura per il logo ITASTEM.

CLICK HERE AND VOTE FOR DAVINCI.WITNESS