One thing is for sure, as a Lineman you never know exactly where or what you will end up doing coming the end of the day. Car wrecks, fallen trees, failing electrical equipment, digging trench with a backhoe or excavator and possibly repairing one of our Digger Derrick Trucks. Just one more reason why I enjoy being a Lineman so much. The diversity of work from day to day keeps the scenery changing. We are required to operate all kinds of equipment associated with the trade and in this case, help a mechanic fix one we broke. I personally didn't do it nor was I one the crew that did it, but we are all Lineman and stuff happens.

A Day With A Lineman #45

We do more than just Linework

If you think something is indestructible, let a lineman have it for a week. That will provide a true test of its durability. No joke!! But here is one that is kind of true. It is an ongoing joke that encompasses Lineman, “if it can be broke, a Lineman will break it” Although there is some truth to that I don’t take ownership of that statement in anyway. :wink:wink I have worked with and been around some Lineman that help turn that “joke” into a truth. Good grief!! They were hard on stuff! Most of the time we fix the stuff ourselves but sometimes you gotta call in the professionals. Possibly pull the dent out of a bumper, repair a broken hose with 4 rolls of electrical tape... you know the usual.

One of our Digger Derrick’s boom was popping and had an abnormal amount of side to side play. When swinging left or right when you would stop and the boom moved an additional 1-2 feet side to side. Ok writing “Digger Derrick” twice is enough. Let’s make this easier, it’s a Line-truck. It’s a crane and has an auger on it for digging pole holes, plus some other goodies for building and maintaining the powerlines. With that sort of “slop” in the boom things could get really dangerous when setting a pole between energized Powerlines. (Doing a Hot Set) So this Line-truck had some serious issues and got removed from service before anything bad could happen. After it was inspected, they determined the main bearing and drive gear of the boom needed to be replaced. The Mechanic said he had never heard or seen this sort of thing happen. As you can imagine this isn’t some easy fix. The part that needs replaced is the part holds the boom to the truck, so the boom needs to be removed.

When my boss asked me and another “mechanically inclined” Lineman to come in and assist the Altec Mechanic in the repair of the Line-truck, I was all about it. I always wanna know how things work and how they are designed. Plus gain a little more knowledge of how to repair stuff. Learning tips and tricks from a “professional” can’t be passed up. First I gotta slam down a couple homemade breakfast burritos before we get started. Can’t be wrenching on an empty stomach, plus I think this is gonna be a long day.

The night before we were going to tackle this project, the mechanic disconnected the hydraulic hoses and electrical connections. So when we arrived it was Go-Time. Well first we needed to make a game plan on how we were going to lift this boom off of the Line-truck. What size of slings/rigging to use, where to install the rigging on the boom, how far away to setup the other Line-trucks to make it easy and take into consideration we were inside and there is a ceiling. So we don’t have full range of the booms and are somewhat limited.

With the auger and auger motor removed the boom weighs in at around 7,500 lbs. With everything on it the weight is just under 10,000 lbs. It has 2 internal sections, one being an insulated fiberglass section. This boom isn’t something you just “take off”. A tandem Line-truck lift is how this is gonna go down.

With the luxury of having a huge shop and two other Line-trucks available, this shouldn’t be too bad. Shouldn’t being the key word here. It never fails something is bound to not go just quite right. That is just from my experience doing these sorts of things. It’s always something. What oh hunk should take an hour, turns into 2. After discussing all the possible scenarios and dangers, we got the two Line-trucks setup and rigged up to the boom with some tension on each of the winch lines.

There are 52 bolts that hold the boom to the bearing and the drive gear to the truck in total. Guess what, they get thrown into scrap never to be used again. One time use. So one at a time they were removed and set off to the side away from all the new parts.

With 4 bolts left, 2 on the bearing and 2 on the gear, the mechanic loosened them up but didn’t remove them. This was done so we could tell how much pick we had on the boom. We didn’t want too much tension on the winch lines and just zip the bolts out. It could cause the boom to “sling-shot” up, shock loading the winch lines. So as the last bolts were loosened up, we increased and decreased the amount of pick we were applying according to what the mechanic was seeing inside the turret of the Line-truck. The turret is a hallowed our portion where the boom bolts to the truck. It’s hallow inside to allow access to hydraulic hoses, bolts, electrical connections, and other parts that need regular maintenance. With all the bolts removed we were ready to lift the boom off of the Line-truck.

Working both Line-trucks in unison, we slowly lift the boom up and off of the truck. With the eyes of the mechanic closely watching for anything that could possible get hung up.

Once it was lifted off the truck we all had to stop and take a look and get some photos. As usual I laughed because for some reason it looked funny to me. Hey I don’t even know why?!?!?

Even the mechanic had his little boom out there. Actually that little guy has some reach.

After we got done with a little photo session, we had to get this boom safely set on the ground.

We kept our movements to one operation at a time so we could stay really smooth and keep the boom level in all directions. We slowly brought it to the side of the Line-truck and set it on the ground. We had to set the other Line-trucks up far enough away to leave room for the boom to sit on the ground. Plus if we were too close, we couldn’t lift our booms high enough to get get the other boom to come towards the lifting trucks. The Line-trucks doing the lifting would hit the ceiling if they were retracted all the way in and raised the boom too far. I really hope that made sense.... As you can see in the photo we were inches away from hitting the heaters that hang from the ceiling.

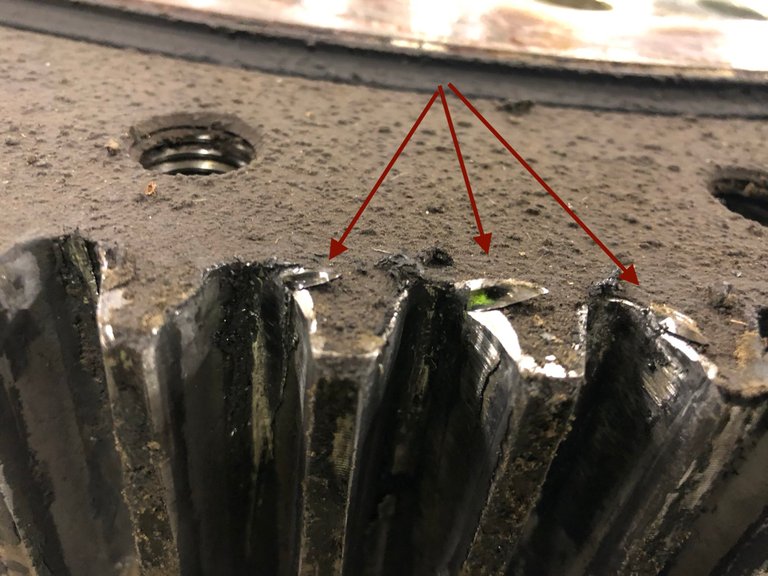

Now that the boom is off and safely on the ground, we have full access to the bearing and drive gear. The mechanic pointed out the damages on the main gear. There were chunks of metal deep in the gear slots from the drive motor.

And you could also see some damaged areas on the top portion of the gear

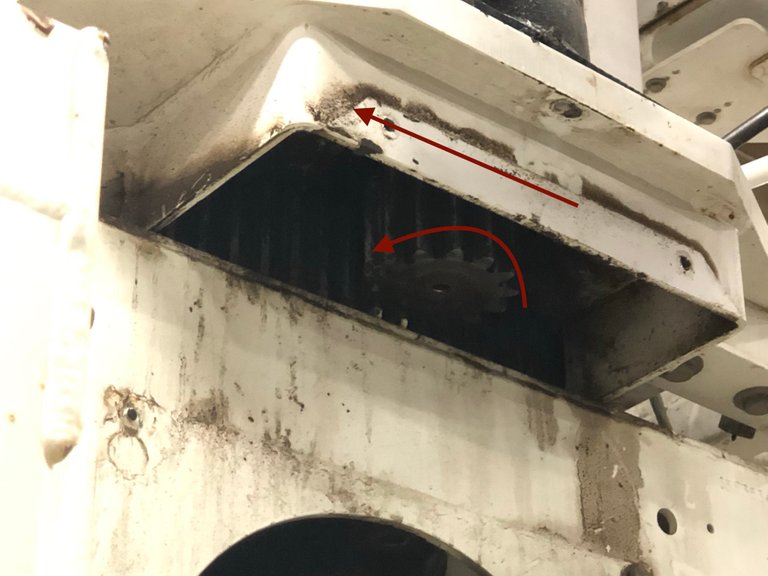

It’s amazing what just that little bit can do to a set of gears. Ok, so the motor mounts on the back of the boom and basically walks the boom around the above gear. Maybe this photo will help explain how it works...

This is the bearing and gear sitting on the turret waiting to be lifted off with the Altec Mechanic’s crane.

We stuck 2 bolts up from the bottom of the bearing bolt holes and spun some eyenuts on the end to use as lifting eyes. You ain’t just picking this thing up by hand.

Now before we could install the new one we had to clean the mounting surface on the turret with some special cleaner. There is a sealant/adhesive that goes under it and dries in 20 minutes, we had to be quick when installing hose 28 bolts. We all believe the reason for this is because you don’t want any contamination under the gear that could cause corrosion or rust. A little time consuming but while 2 guys were cleaning that, I was cleaning up the new gear/bearing. This is it landed on the turret. Check that out!!! Ain’t it shiny??

Now this is where things get real time consuming. The drive gear takes 28 bolts. They have to be tightened down in a certain order. This ensures that there is even pressure on all bolts and on the surface of the gear and mounting plate. After one round of torquing bolts to 165 foot pounds, it was time to get the final torque on them. 325 foot pounds of torque which is achieved by using a 4 foot torque wrench. It’s not that easy to get you arms inside the turret to hold the head of the torque wrench on the bolts. I was like a contortionist in there, uncomfortable as all get out. It wasn’t the funnest part but it had to be done.

Once the 28 bolts were all to the proper torque specifications, it was time to land the boom back on the truck. I set my phone up and did a little time lapse of the process which can be seen Here.

One of the Line-trucks actually locked out due to being overloaded. Which was weird since we just lifted it off earlier. So after a little adjustments we were able to get the boom landed back on the truck.

We had a heck of a time lining up all those 24 bolts and getting them started without cross threading. We couldn’t set the boom all the way down on the bearing, we needed it to float just a little bit so we could move it around and get all the bolts started. I was pushing my weight around while the mechanic got all the bolts started. Just wiggling the boom a little bit was enough. Then we set he boom down and removed the rigging and we were done with the other 2 Line-trucks.

With that out of the way, the other lineman left and I stuck around with the mechanic to finish his up.... it was back to torquing bolts... again. At least we only had 24 to do this time and we didn’t have to give them the pre-torque first.

We had a bunch of little stuff to take care of and ran into an issue with the new drive motor. Sometimes you gotta call the people that make these retrofit kits to fully understand what they have going on. I didn’t get any more photos out of respect for the mechanic. He was really trying to get this all done so he could get home and not have to stay in a hotel for the night. I was busy grabbing tools, cleaning tools, putting fittings together... doing whatever I could to help speed up the process.

Unfortunately after setting the bearing, he didn’t have enough time to drive 5 hours home due to DOT restrictions. To set the bearing the boom is fully extending, both internal booms all the way out. Then the boom has to be at a certain angle, and lift a certain amount of wait and rotate 360 degrees several times in both directions. This sets the bearing, remember the boom is attached to the bearing, which is attached to the drive gear which is attached to the truck. Then guess what we had to do... check torque on all 52 bolts... again!!! Then we were finally done and the crew can have their truck back.

Well I tried my best to document the whole process but things don’t always work out. Getting a job like this done takes priority over snapping photos. Mainly I just wanted to show that as a Lineman we are asked to do more than just Linework. Shoot, sometimes I feel like a psychologist when talking to customers. They go on and on about all kinds of stuff, telling me their life story. I am like, “Hey, I would love to hear about how your horse got stuck in the mud and your husband pulled it out with his bare hands, but I gotta go”.

Like I said before, as a Lineman you just never know what the day will bring... like this...

I hope you enjoyed his episode of A Day With A Lineman. I really enjoy sharing stuff like this with everyone, to show what goes on to keep the lights on. Even if I is fixing something we broke. Catch you all on the next one

Steem On

and

Stay Safe

Everyone

Don’t forget to mention @splatz

when you encounter a post that deserves a good Splattin’

by the @splatz trail

Join the @splatz trail

On Steemauto.com

Where we catch those

Splatworthy Posts

Hot off the Press

Congratulations. We love your post because it's so well written and visually stunning, and we'd love to see it hit the Trending pages of Steem. Our project aims to generate support for posts just like yours!

#trendgineering #trending

Photo Courtesy of Canva

What do you think @theycallmedan, @twinner, @superhardness, @postpromoter, @adsup, @redpalestino, @trafalgar, @blocktrades, @smooth, @azircon, @michealb, @tombstone and whoever else notices this? Spread the word!

@trendthis was founded by @joshman. If you were mentioned and wish not to participate, simply reply to this post stating so. A special thank you to collaborators @azircon, @livinguktaiwan, @minismallholding, @riverflows. Of course this could not be done without the generous support of our participating Orcas and Whales!

Project Supporter: @ocd / @ocdb / @acidyo

Project Supporter: @ steemflagrewards / @enforcer48 / @anthonyadavisii

So, it looks like good linemen run on breakfast burritos...And now I want one too despite the fact it is not breakfast time here.

I would imagine that most people have zero clue what goes on behind the scenes to ensure the lights go on when that switch is flicked. Sure, there's some poles, wires a truck that goes up and down and a few dudes in hi-vis and hard hats...How hard can it be?

Well...This sure dispels that little misconception.

Seems like you boys know what's up when it comes to your jobs and don't just connect wires and look good in hi-vis. A great post here mate, as always. Nice work on the tools too brah. (Curated for curangel.)

Ain’t nothin’ wrong with a breakfast burrito addiction... I did forget to mention that we got our grub on at a Chinese buffet for lunch. Hey when the Altec guy is payin’ might as well “filler’ up”.

That is my goal, to bring.... I hate to put it this way... light... to what goes on. We don’t just flip a switch and the lights come back on. We don’t just dig holes, set poles, and string wire.... Sometimes I feel like a lumberjack or mechanic, even standing on the side of the road flagging traffic while my boys do Hot work... (not my favorite thing to do but sometimes you get the short straw.

We are currently getting some snow so I really hope the trees stand good and tall this go around. Lol

Oh yeah, nothing like a free tank of Chinese food huh? Nice work.

Yeah, you do a good job of demonstrating the complexities, challenges and cool stuff about your job. I don't know why, but I wasn't following you. I think maybe because you resteem a lot, which I am writing about now actually, but I followed anyway.

Good luck with the snow and trees.

I just wish I was still doing helicopter work. That is the fun stuff!! No worries, I don’t resteem that much stuff... at least I don’t think so anyway. Lol. Shoot I don’t have much available time to spend one here. I have too much stuff going on.... at least I am not bored. 😜😜 Next project... swap axles from a 2005 Ford F-350 into my 1997 F-350... this is gonna be good.... when it happens. Lol.

Helos are legit!

Oh cool, working on F-trucks...Now that's post-worthy!

EDIT: Just took another look at your blog. Looks like one RS a day or so...The thing that got me was that you don't post much yourself so it looked like loads of RS posts. All good. Following now anyway.

It’s gonna be fun... once winter decides to leave and I can tear into the parts truck and tank those axles out... I need a shop at my house really bad. Lol

Yeah, I can imagine working in the snow isn't much fun. Can't you use the workshop at work?

Congratulations @jlsplatts! You have completed the following achievement on the Steem blockchain and have been rewarded with new badge(s) :

You can view your badges on your Steem Board and compare to others on the Steem Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPTo support your work, I also upvoted your post!

Do not miss the last post from @steemitboard:

Vote for @Steemitboard as a witness to get one more award and increased upvotes!

This post was shared in the Curation Collective Discord community for curators, and upvoted and resteemed by the @c-squared community account after manual review.

@c-squared runs a community witness. Please consider using one of your witness votes on us here

I'll admit, I didn't take much of that in, but it reads like a full on day. Off to get my own burrito now, my stomach's growling!

@tipu curate

Upvoted 👌 (Mana: 0/3 - need recharge?)

This reminds me of NCRs I get at work. The workers at site end up in all kinds of silly situations.

My favourite was when our HSE people found evidence of urination in a non-designated area. The poor dude literally had a picture of himself sent all over the place with his face blurred, but his name had to go on the report because he was the acting supervisor.

DAHAHAHA!!! There was a guy at the old place I worked that didn’t like a meter reader parking in his spot. He would put Glove Dust(basically baby powder that we use inside our rubber gloves to make it easier to take on and off.) in the vents of his work truck, put silicone lubricant (we use this when making watertight seals on underground cable) under his door handles. It was happening constantly. Then they called him in and he denied everything. Then they pulled the video... “nope, that’s not me!” .... LIAR.... yep he got fired. Lol.

Oh BTW, glove dust in the vents is awesome!!! Just make sure you can turn the car on, out the vents you put the dust in on full blast and shit the car off... once they get in and start it.... Just call them Whitey. 😂😂

That sounds like some good sabatoge. How did they get it in the vents? I'd lock my vehicle and make sure I have a decent cabin filter.

Our guy didn't get fired, he just had to sign the report saying the team had completed additional training to prevent further incidents. I heard the crew teased him badly.

Congratulations @jlsplatts!

Your post was mentioned in the Steem Hit Parade in the following category: