Dear friends,

This is a gargantuan chapter, which took years of research to write. It's so big Steemit wouldn't allow me to post it all, so I had to split it in two parts.

I regularly see posts today going viral on Facebook where automation technologies are hailed as great innovations and a sign of the future to come. What follows was written five years ago, and yet it stands the test of time remarkably well, showing a vision of the future which is coming true before our very eyes.

We continue our journey into the future of technology, automation, and the economy. Last week we left off at Chapter 6: Artificial Intelligence, and now I'm publishing in full on Steemit the seventh chapter of my book Robots Will Steal Your Job, But That's OK.

Happy reading and follow me on @federicopistono to get updates on future chapters!

Chapter 7: Evidence of Automation

We understand what exponential growth means. We have seen how information technology has grown over the last 150 years. Let us see how far has that brought us.

I started gathering the evidence for this chapter as soon as I decided to write the book in October 2011. Since then, I have collected more than 300 articles, all from reputable and reliable sources. These stories cover machines that act like us, computers that “think” better then us, and robots that perform unimaginably complex tasks. Every day I opened my news feed to find something new and then add it to my list. At a certain point I realised I had to stop. I knew there could never be an end to this trend, but I did not expect it to grow so quickly. Once again, I underestimated the power of the exponential function. As the list started to grow out of proportion, I decided I would freeze it, finish the book, and publish, or else I would never finish it. To offer readers a current resource, I will continue to post updates on the website http://robotswillstealyourjob.com . In this book, rather than a sterile and long list of technologies, I picked only a few that I think are most relevant for the sake of the argument.

1.1 AUTOMATED SHOPPING

You might not think of them as such, but vending machines are actually a primitive type of robot. Their function is very simple. They keep an inventory, have an electronic display, accept money, and provide you with the item you purchased. It is a 30-year-old technology and it has not progressed much since then. Or, has it? In Europe and the US we do not think much of vending machines, but that is just because we have not taken them seriously. In Japan, however, where they have high population density, limited space, high cost of labour, low rates of vandalism and petty crimes, and people shop mostly by bicycle or on foot, vending machines are taken very seriously.

In Japan there are about 8.6 million vending machines, one for every 14 people, the highest number pro capita in the world.[1] These robots, known there as jido-hanbaiki (from jido, ”automatic”; hanbai, ”vending”; and ki, ”machine”), often abbreviated jihanki, are widespread and commonly used for all sorts of goods: not just newspapers, snacks, and drinks, but also books, DVDs, condoms, ice-cream, hot instant noodles, rice, magazines, glasses, boiled eggs, umbrellas, neck ties, sneakers, vegetables, iPods, live lobsters, Onsen (hot spring water), and even Buddhist prayer bead-rolls. Sure, we can laugh at it, but doesn’t it make sense? The days when you had the little shop just around the corner – with a smiling person who owned the shop, knew what they were doing, and could give you real guidance and assistance – are quickly disappearing.

Most commercial transactions of physical goods today are made at the mall and huge supermarket chains. The cashiers at these companies work part-time, as one of the multiple jobs they hold because just one job will not provide the money they need to pay their rent, medical bills, student loads, mortgages, etc. The truth is that it would make a whole lot of sense for society to have a shopping mall where most things are automated. The problem with that, of course, is that people currently working there would find themselves in deep, deep trouble.

Imagine this. You walk into a store and you have an interactive map on your cell phone showing you where all the items are. You can search for items, filter them by categories, and get information on each single product that goes far beyond nutrition facts; you can trace the production process, the companies behind it, and dynamically compare products based on your search criteria. You can also read reviews from other people about these products, just like on Amazon.com today. Before leaving with your items, you stop for a few seconds in an assessment zone that receives signals from RFID chips in the merchandise. Then you swipe your credit card, or just accept the payment request on your cell phone. The whole process, the time between when you decide to leave the store and the moment you can actually walk out, takes less than 10 seconds. No human was involved in this, no human was required. No queues, no waiting time.

Sound futuristic? Every piece of technology needed to make this happen already exists, and has existed for many years. Then why is it not in place already? Why are we not seeing this trend expanding to all retail stores? Maybe it is expensive to deploy such a system. Actually, it would be much cheaper than having to employ humans to do the job. “But you need human contact! What about the value added that only a human employee can offer?” Have you ever worked at a mall? If so, how motivated were you and how long did that last? “But you need human workers to place the products on the shelves!” Actually, even that technology is already available, though it is more recent than the others. Some warehouses are already completely automated, and require only operators to work and handle the entire task. Pallets and product move on a system of automated conveyors, cranes, and automated storage and retrieval systems coordinated by programmable logic controllers and computers running logistics automation software. Their accuracy and productivity far exceeds that produced by human labour. These machines are faster, more precise, they can lift huge weights without having to deal with back problems, they work day and night, and do not require much maintenance.

Amazon.com recently made a $775 million purchase of Kiva Systems, a manufacturer of bright orange robots that scuttle around warehouses filling orders[2]. CNN has a video of the system operating (see the link in the previous footnote or the book website). It is a pretty amazing sight. Hundreds of robots transporting merchandise around immense warehouses, with clockwork precision and perfect timing, as if dancing to a silent piece of music written in code of zeroes and ones. These robots are smart enough to put the items in the most convenient place and distance, based on how frequently they are needed, how heavy they are, and many other criteria. They work 24/7 and never make mistakes. The application of similar automated systems to supermarkets and shopping malls is a minor engineering issue, one that can easily be solved in a few months, if there was ever the intention to do so.

If this is all possible, why are we not seeing it?

Tesco is the third-largest retailer in the world measured by revenues (after Walmart and Carrefour) and the second-largest measured by profits (after Walmart). Tesco has a large market in South Korea (where they are branded as “Home plus”), second only to E-Mart mainly because that company has more stores. As one might expect, they wanted to increase profits. The typical approach would require them to build more stores in order to reach E-marts level of distribution in the country. They opted for a different strategy, one that uses more automation and less workers.

Picture yourself in Korea going to work. You need a few things for dinner, but don’t have much time. While waiting for the next subway train to arrive, you see the walls covered with displays that look like supermarket shelves. You use your cell phone to scan the QR code on the items you want and then check out. When you get home, you will find your groceries have been delivered to your doorstep. Quite convenient, isn’t it? The results of this experiment are in: online sales between November 2010 and January 2011 increased by 130%, with the number of registered members rising by 76%. Home plus had become the number one online store, while successfully raising the stakes in the offline market[3].

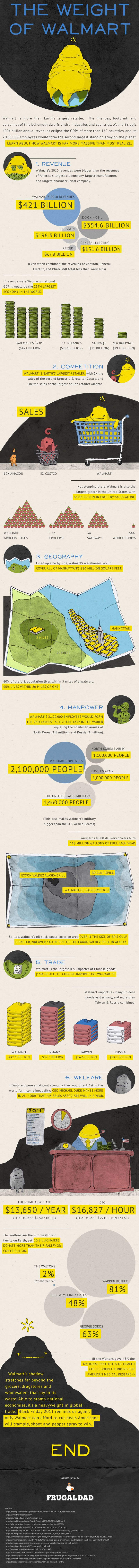

This continuing trend could potentially destabilise the economy. Consider the millions of employed who would be affected by it. If Walmart were to put this technology in place on a systemic level (automated restocking, shopping, and delivery), the consequences to those currently employed by them would be disastrous. It would be practically impossible for most of them to find another job. The average person does not realise how big Walmart really is. Today, Walmart is the largest retailer on the planet. In fact, it is much more than that: the finances, footprint, and personnel of this behemoth dwarf entire industries and countries4 . Its epic $421 billion annual revenues eclipse the GDP of more than 170 countries. Its 2.1 million employees could form the second largest standing army on the planet. Walmart’s 2010 revenues were bigger than the revenues of the largest oil companies, the largest manufacturer, and the largest pharmaceutical company in the United States. Even when combined, the revenues of Chevron, General Electric, and Pfizer still total less than Walmart’s. To put this in perspective, if Walmart were a country, its GDP would be the 25th largest economy in the world (twice the size of Ireland’s). If Walmart were to initiate an aggressive automation strategy, in just a few years it could easily run its business with less than 100,000 employees. That would leave 2 million people, mostly uneducated and unskilled workers, out of a job. Where would these people go? And what would they eat? What will happen to their families?

In the past, we have seen automation cutting the workforce, but unskilled workers all gravitated towards places like Walmart to find an easy (although very unsatisfying) job. This is one of many unspoken tragedies of the so-called modern culture. The idea that the greatest aspiration a person could have is to work some mechanical and monotonous job, so that they can pay the bills, is an insult to the dignity of every individual. Each human being, from the moment they are born, is an invaluable masterpiece, capable of greatness beyond what we can conceive today. To even consider the proposition that we should hang on to an economic system that hinders innovation and automation, in order to preserve repetitious and mindless jobs, shows the deep loss of perspective and aptitude of our out-dated institutions.

If Walmart begins automation (and I suspect they will), there would be no coming back for the shopping industry. It is an irreversible process. The replaced jobs will not come back. But having removed these jobs, what will millions of people do?

Wait before you answer, we are not quite done yet.

1.2 AUTOMATED MANUFACTURING

The advent of automation in the manufacturing industry is generally well-known. It has been a century since we started using machines to increase our productivity. Just think of a car factory. The assembly line developed by Ford Motor Company between 1908 and 1915 made automated assembly widespread and mass production brought unprecedented social transformations. By utilising the old Latin proverb divide et impera (divide and conquer), we were able to transform long and difficult tasks into sets of many small and simple-to-execute mechanical operations. This approach worked well with machines which, for a century, integrated with humans in a fruitful cooperation.

Robots were displacing human workers, but we always found something else to do, because of mainly two reasons:

- There was enough time to adjust and learn new skills.

- Some operations were too complex for machines to do, or the cost of creating a machine capable of performing such a task was too high. Why go through the trouble of programming a complex robot to do something cheap labour could accomplish more easily and at less cost?

Such was the past, but things are different now. Labour is no longer so cheap. Human development is finally occurring on a mass scale.People are (justifiably) demanding their rights. Even though there are still millions who work in conditions that we might consider slavery by today’s standards, the working conditions and standards are raising everywhere, even in relatively under-developed countries. On the other hand, however, algorithms are exponentially improving, robotics technology is developing rapidly, and machines are now becoming cheaper to build (even for complex tasks). We are already seeing the effects of this everywhere.

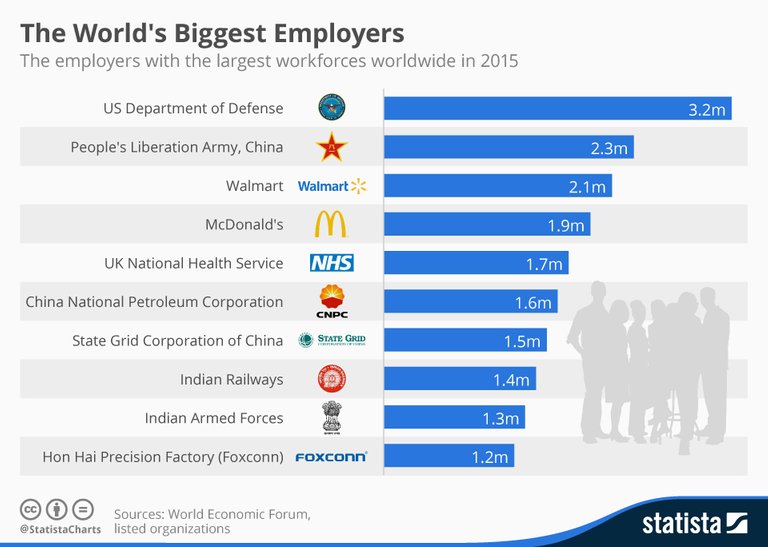

Foxconn is the largest maker of electronic components in the world and the largest exporter in Greater China,[5] [6] with an annual revenue of more than 100 billion dollars.[7] They make virtually anything. If you have an iPad, an iPhone, a Kindle, a PlayStation 3 or an Xbox 360, chances are very good that Foxconn made it. Without counting national public services, Foxconn comes out as the third largest employer in the world with an impressive 1.2 million workers, right after Walmart (2.1 million).[8] It has contracts with Acer, Amazon.com, Apple, Cisco, Dell, Hewlett-Packard, Intel, Microsoft, Motorola, Nintendo, Nokia, Samsung, Sony, Toshiba, and just about any major tech company you can think of. Foxconn is not a company: it is an immense monster, an electronics supergiant that is singlehandedly responsible for nearly half of all such technological production in the world.[9]

If they were to displace their 1.2 million workers, things would turn ugly for many people. As it happens, as recently as last year (2011), Foxconn announced that they intended to deploy an army of robots in order to “replace some of its workers with 1 million robots in three years to cut rising labor expenses and improve efficiency.” – said Terry Gou, founder and chairman of the company.[10] It still remains unclear if they are really going through with the plan, and how many workers would be displaced by this initiative, but it appears that they have already launched and built a Research and Development facility and a factory in Taiwan to build their own robots; and have begun to hire some 2,000 engineers to drive the project forward.[11] It appears that Foxconn is committed to the automation of their business, and it should come as no surprise. Why wouldn’t they? Robots are cheaper and more reliable than human workers, they do not ask for vacation, they do not commit suicide, they do not protest for more rights, and they can ensure the company’s profits – which is what matters most for a multinational corporation and its stakeholders.

Rumors and stories surrounding Foxconn’s operations began to spread after a wave of suicides was reported by the news in the Western world. After fourteen workers were found dead in 2010, some twenty Chinese universities compiled a report in which they described Foxconn factories as labour camps and detailed widespread worker abuse and illegal overtime.[12] Stories of overcrowding, tiny living accommodations, impossibly long and exhausting work hours, and security guards beating workers to death are just hints of what happens in those hellholes; what manages to overcome the great firewall of censorship of China to reach our digital shores.[13] After protests began to kindle in the US and in Europe, demanding better working conditions, the morbid response from Foxconn executives was that they would install suicide-prevention nets at some facilities to catch the people who tried to commit suicide by jumping off the building (I am not joking), and they promised to offer higher wages at its Shenzhen production bases. But they also did something else. Workers are now forced to sign a legally binding document guaranteeing that they and their descendants would not sue the company as a result of unexpected death, self-injury, or suicide.[14]

The saddest part of this story is not the that workers at Foxconn live in horrifying conditions. What is truly astonishing is that Foxconn actually provides higher wages, better working conditions, and has a lower suicide rate than the average Chinese company.[15] Foxconn is merely the story that made it into the news and we suddenly became all outraged by it. But there is nothing to be surprised about: this is the very nature of current socio-economic system, efficiency and, consequently, profits are more important than human lives.

Foxconn is not the only company moving in the direction of automation. Canon announced in June 2012 that some of its camera factories will phase out human workers in an effort to reduce costs. We can expect robots to be making the next generation of cameras, possibly as soon as 2015. Of course, the company’s spokesman Jun Misumi was quick at dismissing the idea that this move would mean layoffs at Canon when he told the Associated Press, “When machines become more sophisticated, human beings can be transferred to do new kinds of work“.[16] These are nice words, but I doubt they will hold true. Assembly line workers have been performing the same mindless, repetitive, mechanical jobs for years. Before they started working at a factory, they were masterpieces of evolution and natural selection, individuals with imagination, dreams, and aspirations. They had endless possibilities. They could have become artists, scientists, and musicians. They could have been the drivers of new amazing discoveries that pushed humanity forward. After a few years in a factory they each were just another pair of hands in an endless sea of moving parts, their dreams were crushed, their hopes and aspirations reduced merely to bringing home just enough to keep their heads above water for another month. I doubt these people will all suddenly become engineers, industrial designers, sales managers, and computer scientists – assuming that a proportionally larger number of those jobs will be needed at Canon by 2015 (they will not).

Foxconnn and Canon are only two of numerous examples. China is increasingly replacing its workers with robots [17] and now even major newspapers are realising this. Just a few days ago (at the time of this writing), The New York Times came out with a 6-page piece titled “The Machines Are Taking Over”[18] and The Wall Street Journal says “Why Software Is Eating The World”.[19] I suspect these types of articles will only increase in the near future.

The trend is clear. Companies in the manufacturing sector are automating and the typical statement that “people will find something else to do” is simply a cop-out that does not look at the reality of the situation – that change is happening too fast and that most workers who will be replaced by machines will not have the time to learn new skills. Assuming, of course, that we could somehow find a number of new jobs equivalent to the number of displaced workers – I very much doubt we will (more on this in Chapter 9).

1.3 3D PRINTING

You are in your house having a party with some friends. As it happens, one of them drinks a little bit too much and drops a glass on the floor. Typically you would have to go out and buy a new one, or get online and order it. But, you could also go the computer, download the CAD file of the glass, press print, and watch your 3D printer as it makes a perfect replica of the glass to replace the one your friend broke. Pretty neat, but not really a game changer.

Now imagine you are Captain of a container ship. You left from China a few days ago on your way to San Francisco and now you are in the middle of the Pacific Ocean. Suddenly the ship stops and the Chief Engineer comes to the bridge to tell you that a part of the engine just broke. He does not have a spare part and has no way of making a replacement. You realise you are stranded. All you can do is call for help, wait, miss the deadline, and lose a lot of money. Not a pretty situation. Or, you could have a 3D printer. Select the file, press print, fix the engine, and be on your way in less than an hour. That is pretty neat.

It is like the replicator in Star Trek[20] . “Tea. Earl Grey. Hot.” Many fans of The Next Generation will recognise these words. Just say the word and anything you want will appear right in front of your eyes. How far are we from this fantastic technology?

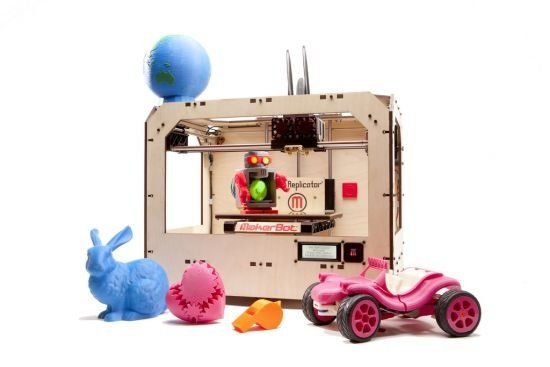

Today 3D printing is a multi-billion dollar industry, and it is growing exponentially[21] . There are many types of 3D printer, from DIY Open Source models to sophisticated commercial products, spanning from a few hundred to many thousands of dollars. The idea behind it is simple. Just like regular inkjet or laser printers, they start from a file on your computer and then manipulate matter to create what you want. The only difference is that they can print in three dimensions instead of two, and they can use many different materials. 3D printers are already used for rapid prototyping, rapid manufacturing, and many DIY enthusiasts and hackers use them at home for fun. Although these machines are not quite ready to replace all commercial production, they surely are on their way. The hugely successful Open Source project RepRap gave rise to a plethora of successors, thanks to its openness and incredible community of people around it. Just to name of few of the available 3D printers under €1,000, we have MakerBot Thing-O-Matic, The Replicator, Ultimaker, Shapercube, Mosaic, Prusa, Huxley, Printrbot. They all came into existence in just a couple of years, and if you buy it in kit form and assemble it yourself, you can get one for less than €300.

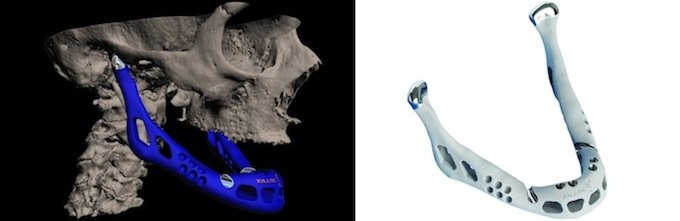

Printers in the lower price range are still very limited, both in terms of resolution (you can see the imperfections) and the materials they can use (mostly plastics). However,commercial printers are different. At the time of this writing, the most sophisticated machine can print with an accuracy of 16 micrometres[22] . That’s 0.016 millimetres! To put things in perspective, the resolution limit of the human eye is about 100 micrometres, and the iPhone 4’s ‘Retina display’ pixels are 78 micrometres in width[23] . These machines can print multiple materials, such as ABS plastic, PLA, polyamide (nylon), glass filled polyamide, stereolithography materials (epoxy resins), silver, titanium, wax, polystyrene, ceramics, stainless steel, titanium, photopolymers, polycarbonate, aluminium and various alloys including cobalt chrome.[24] You can print in colour and even create structures that are more intricate than any other manufacturing technology – or, in fact, are impossible to build in any other way.[25] You can create parts with moving components, hinges, and even parts within parts.

3D printers are not just used as an alternative to standard manufacturing. People have printed really cool-looking personalised prosthetic limbs,[26] bone-like material,[27] and even human organs.[28] [29]

A very inspiring example of how 3D printers can be used for the betterment of humankind comes from Scott Summit and his team composed of Industrial Designers and Orthopaedic Surgeons, whose mission is to bring more humanity to people who have congenital or traumatic limb loss. In their words: “Each of our bodies is unique, as are our tastes and styles. Humans are anything but one-size-fits-all, and we want to recognise that fact. We achieve this by creating products that allow our clients to personalise their prosthetic legs. Our hope is to enable our clients to emotionally connect with their prosthetic limbs, and wear them confidently as a form of personal expression.”[30] For people who have lost a leg, life can be very difficult. So, instead of hiding their defect and feeling ashamed of it, they can show it with pride, reclaiming that lost connection with their body.

I expect we will soon see a rapid increase in the quality of these machines, with the costs dropping so significantly that they will become an everyday commodity, much like a microwave oven can be found in most houses. Marketplaces like iTunes, Android, and Amazon.com will follow, along with their ’pirate’ and Open Source counterparts. In fact, the Open Source community is already leading the way (as always). Thingiverse has thousands of free designs that people can download, print, or improve upon,[31] and The Pirate Bay recently announced a new section called “Physible,” CAD designs of physical objects, legal or not[32] . In a few years, most of us will all have a micrometre-precision 3D printer that prints multiple materials and colours in our house. Designs will be extremely cheap, or they will cost nothing at all.

Today 3D printing is little more than a hobby, but it will probably soon become a game changer for entire industries. Another advantage of 3D printing is that instead of conforming to sizes and shapes defined by the economies of scale, the object can adapt to you, instead, moving from an economy of mass production to an economy of mass personalisation. How many jobs today rely on manufacturing? We’ll probably see them disappear, too.

1.4 AUTOMATED CONSTRUCTION

Typically, it can take from 6 weeks to 6 months to build a 2-storey house in the US or Canada, mostly because dozens of humans do all the work. However, we have newer and smarter ways of building houses, which some are beginning to use. In China, we can construct a 30-storey skyscraper with all modern comforts in 15 days. That’s 2 storeys per day, non-stop. The building is made from prefabricated parts and can withstand earthquakes of magnitude 9. It has excellent insulation systems, is five times more efficient than regular hotels, and has smart systems for air circulation and quality control[33] . The implications of this are significant: we have designed a system that will let you build anywhere, to construction tolerances of +/- 0.2 mm, in just a few days[34].

This is what we can do today. Let us have a look at tomorrow, shall we?

Contour crafting is a construction process that uses a computer-controlled crane or gantry to construct buildings rapidly and efficiently without manual labour. It is possible that within a decade this technology will advance so much that we will be able to upload the design specification to our computer, press print and watch massive robots spit out a concrete house in less than a day. No humans required, except for a few supervisors and designers. You might be thinking this is like a huge 3D printer! And you would be right. The idea is the same, just the scale and the materials differ.

Contour crafting is now under development by Behrokh Khoshnevis of the University of Southern California’s Information Sciences Institute. It was originally conceived as a method to construct moulds for industrial parts, but Khoshnevis decided to adapt the technology for rapid home construction as a way to rebuild after natural disasters like the devastating earthquakes that have plagued his native Iran.[35] Khoshnevis claims that his system could build a complete home in a single day, and its electrically powered crane would produce very little construction material waste. This is particularly interesting because today a standard home construction project creates 3 to 7 tonnes of waste, as well as exhaust fumes from machinery and vehicles,[36] not to mention the thousands of deaths each year which result from workplace accidents.[37] Contour crafting could reduce costs, lessen our environmental impact, and save materials and lives. Of course, many jobs would disappear, too.

Some industries and institutions have already shown interest in this technology. Caterpillar, Inc. has provided funding for the Viterbi project since the summer of 2008,[38] NASA is evaluating Contour Crafting for its application in the construction of bases on Mars and the Moon,[39] and Singularity University graduate students established the ACASA project with Khoshnevis as the CTO to commercialise Contour Crafting.[40]

1.5 AUTOMATED JOURNALISM

You might think that writing is one of those things that machines will never do. Sure you can program them to generate text, but it will sound sterile and fake. It would have no soul. You would be able to spot it in a second, right? Right?

Let us see how well you do. Below are the opening lines of three story pieces written about a baseball game. Can you tell which were written by flesh-and-blood humans, and which (if any) were written by a computer?

a) The University of Michigan baseball team used a four-run fifth inning to salvage the final game in its three-game weekend series with Iowa, winning 7-5 on Saturday afternoon (April 24) at the Wilpon Baseball Complex, home of historic Ray Fisher Stadium.

b) Michigan held off Iowa for a 7-5 win on Saturday. The Hawkeyes (16-21) were unable to overcome a four-run sixth inning deficit. The Hawkeyes clawed back in the eighth inning, putting up one run.

c) The Iowa baseball team dropped the finale of a three-game series, 7-5, to Michigan Saturday afternoon. Despite the loss, Iowa won the series having picked up two wins in the twinbill at Ray Fisher Stadium Friday.

Take a moment and try to guess. They all look pretty similar, but which one is the product of a lifeless machine? All of them? None? It is time for the moment of truth. If you thought article c) was computer generated, then you would be right. I can picture you going back a paragraph and read the opening lines again thinking, “Yeah, now that I see it, it makes sense. None of them are Pulitzer Prize material, but c) definitely looks more dull than the others. It must be computer generated”. Somehow your mind has already internalised this fact, and it is starting to reinforce it. If you go back and read them again, I am sure you can spot the flaw right away. As with subliminal messages, once you are aware of them, they do not work any more.

Sorry to disappoint, but you have just been trolled.[41] The correct answer is in fact b), that is the computer generated article.[42] If you fell for the trick, do not feel too bad. Narrative Science and other companies have many customers in the big media industry that make use of this technology already. Most people just do not notice. The identity of these media firms is secret, but we know they are there because the companies that created these intelligent algorithms have earned several million dollars in a very short time. This software is currently mainly used for sports, finance, business, market, and real estate reporting. I will not go so far as to say that the algorithms developed today can replace all journalists. And I do not expect software to write an editorial about the lack of human rights in China any time soon. But remember, to disrupt an industry you do not need to replace all jobs within it, just a significant fraction.

I have noticed that often people tend to express some form of the following logical fallacy:

If you can find one example of a person that cannot be replaced by machines, then the argument of technological unemployment is invalid.

On the contrary, I would argue that if you have to rely on that single special example to present your argument in favour of humans, you have just proved my point. The average person within that job type is bound to fall victim to technological unemployment.

Now, just imagine if a few of the big players (e.g. Google, Amazon.com, etc.) that are collecting millions of terabytes of personal information about our reading habits decide to enter the market of automated journalism. We have already seen how Google news has affected news sites by collecting articles into categories and creating personalised news feeds faster and better than any human can. What if these software start to write the stories themselves? How long do you think will that take? If you are thinking decades, you are in for a surprise.

This chapter was to big to post it all at once on Steemit, so I had to split it in two parts. Follow me on @federicopistono to get notified when Part 2 comes out!

Chapter 7 (Part 1) Notes

- According to the Japan Vending Machine Manufactures Association website, there are 8,610,521 vending machines in Japan, or one machine for every 14 people.

http://www.jvma.or.jp/information/qa_01.html - Amazon buys army of robots, Julianne Pepitone, 2012. CNN Money.

http://money.cnn.com/2012/03/20/technology/amazon-kiva-robots/index.htm?hpt=hp_t3 - Tesco Homeplus Virtual Subway Store in South Korea

- The Weight of Walmart (Infographic)

http://frugaldad.com/2011/12/01/weight-of-walmart-infographic/ - Strikes End at Two Chinese Automotive Suppliers, 2010. Reuters.

http://www.reuters.com/article/idUSTRE66L0A220100722 - Table 3. The Circuits Assembly Top 50 EMS Companies, 2009. Circuits Assembly.

http://circuitsassembly.com/cms/http://robotswillstealyourjob.com/sites/robotswillstealyourjob.com/files/book/stories/Articlehttp://robotswillstealyourjob.com/sites/robotswillstealyourjob.com/files/book/1003/1003buetow_table3.pdf - Forbes Global 2000: The World’s Biggest Companies – Hon Hai Precision Industry, 2010. Forbes.

http://www.forbes.com/companies/hon-hai-precision/ - Which is the world’s biggest employer?, 2012. BBC News.

http://www.bbc.co.uk/news/magazine-17429786 - Apple partnership boosting Foxconn market share, 2010. CNET.

http://news.cnet.com/8301-13579_3-20011800-37.html - Foxconn to replace workers with 1 million robots in 3 years, July 2011. Xinhuanet News.

http://news.xinhuanet.com/english2010/china/2011-07/30/c_131018764.htm - Companies Making The Necessary Transition From Industrial To Service Robots, 2012. Singularity Hub.

http://singularityhub.com/2012/06/06/companies-making-the-necessary-transition-from-industrial-to-service-robots/ - Foxconn Factories Are Labour Camps: Report. South China Morning Post.

- Foxconn Security Guards Caught Beating Factory Workers, 2010. Shanghaiist.

http://shanghaiist.com/2010/05/20/foxconn-security-guards-beating.php - Revealed: Inside the Chinese Suicide Sweatshop Where Workers Toil in 34-Hour Shifts To Make Your iPod, 2010. Daily Mail (London).

http://www.dailymail.co.uk/news/article-1285980/Revealed-Inside-Chinese-suicide-sweatshop-workers-toil-34-hour-shifts-make-iPod.html - Suicides at Foxconn, 2010. The Economist.

http://www.economist.com/node/16231588 - Canon Camera Factory To Go Fully Automated, Phase Out Human Workers, June 2012. Singularity Hub.

http://singularityhub.com/2012/06/06/canon-camera-factory-to-go-fully-automated-phase-out-human-workers/ - China Is Replacing Its Workers With Robots, 2012. Business Insider.

http://www.businessinsider.com/credit-suisse-chinese-automation-boom-2012-8 - The Machines Are Taking Over, Sep. 14, 2012. The New York Times

http://www.nytimes.com/2012/09/16/magazine/how-computerized-tutors-are-learning-to-teach-humans.html - Why Software Is Eating The World, 2011. The Wall Street Journal.

http://on.wsj.com/pC7IrX - In the TV series Star Trek, a replicator works by rearranging subatomic particles, which are abundant everywhere in the universe, to form molecules and arrange those molecules to form the object. For example, to create a pork chop, the replicator would first form atoms of carbon, hydrogen, nitrogen, etc., then arrange them into amino acids, proteins, and cells, and assemble the particles into the form of a pork chop.

http://en.wikipedia.org/wiki/Replicator_(Star_Trek) - Will 3D Printing Change The World?, 2012. Forbes.

http://www.forbes.com/sites/gcaptain/2012/03/06/will-3d-printing-change-the-world/print/ - Objet Connex 3D printers.

http://www.ops-uk.com/3d-printers/objet-connex - iPhone 4’s Retina Display Explained, Chris Brandrick, 2010. PC World.

http://www.pcworld.com/article/198201/iphone_4s_retina_display_explained.html - 3D printing.

http://www.explainingthefuture.com/3dprinting.html - A primer on 3D printing, Lisa Harouni, 2001. TEDSalon London Spring 2011.

http://www.ted.com/talks/lisa_harouni_a_primer_on_3d_printing.html - 3D-printed prosthetics offer amputees new lease on life, 2012. Reuters.

http://www.reuters.com/video/2012/02/27/3d-printed-prosthetics-offer-amputees-ne?videoId=230878689 - 3D printer used to make bone-like material, 2011. Washington State University.

http://wsutoday.wsu.edu/pages/publications.asp?Action=Detail&PublicationID=29002&TypeID=1 - Making a bit of me, a machine that prints organs is coming to market, 2010. The Economist.

http://www.economist.com/node/15543683 - Transplant jaw made by 3D printer claimed as first, 2012. BBC News.

http://www.bbc.com/news/technology-16907104 - What drives us. Bespoke.

http://www.bespokeinnovations.com/content/what-drives-us - Thingiverse.

http://www.thingiverse.com - First Downloaded and 3D Printed Pirate Bay Ship Arrives, 2012. TorrentFreak.

http://torrentfreak.com/first-downloaded-and-3d-printed-pirate-bay-ship-arrives-120205/ - 30-storey building built in 15 days Construction time lapse. YouTube

- Time lapse captures 30-story hotel construction that took just 15 days to build, 2012. The Blaze.

http://www.theblaze.com/stories/time-lapse-captures-30-story-hotel-construction-that-took-just-15-days-to-build/ - Annenberg Foundation Puts Robotic Disaster Rebuilding Technology on Fast Track, 2005. University of Southern California School of Engineering.

http://viterbi.usc.edu/news/news/2005/news_20051110.htm - House-Bot, December 30, 2005. The Science Channel.

- Census of Fatal Occupational Injuries Summary, 2010. Bureau of Labour Statistics.

http://bls.gov/news.release/cfoi.nr0.htm - Caterpillar Inc. Funds Viterbi ‘Print-a-House’ Construction Technology, 2008. University of Southern California School of Engineering.

http://viterbi.usc.edu/news/news/2008/caterpillar-inc-funds.htm - Colloquium with Behrokh Khoshnevis, 2009. Massachusetts Institute of Technology.

http://www.media.mit.edu/node/2277 - GSP-09 Team Project: ACASA, 2009. YouTube

- Problem?

http://www.urbandictionary.com/define.php?term=trolling - Are Sportswriters Really Necessary? Narrative Science’s software takes sports stats and spits out articles, Justin Bachman, 2010. Newsweek.

Publication on Steemit

I decided the share my book, the result of years of work and research, with the Steemit community for free, to spark a debate and to raise awareness on this pressing social issue.

Previous Chapters

- Chapter 1: Unemployment Today

- Chapter 2: The Luddite Fallacy

- Chapter 3: Exponential Growth

- Chapter 4: Information Technology

- Chapter 5: Intelligence

- Chapter 6: Artificial Intelligence

If you'd like to support my work, you can:

- upvote this post 😊

- follow me on @federicopistono to get updates on future chapters!

- get a copy of the book

"Robots [...]" was an international success published in seven languages, featured on Forbes, the BBC, The Wall Street Journal, The Economist, New Scientist, CNBC, and was subject of discussion at numerous universities as well as the European Commission, the Nobel Peace Center and the Italian Parliament.

Read my article, you will like it :)

https://steemit.com/realworld/@vapekings14/waking-life-2001

Great post!!!