Much like the spark plug in your car, if you use mechanical relays with the right amount of voltage and duty cycle the contacts will eventually "wear out". In most situations this is of no concern, the cycles that a relay will go through in a given use case will not exceed its design. So, let me explain the scenario..

I have a set of amateur radio antennas outside, on a 2-axis rotor - one for azimuth control, one for elevation. The movement is controlled by a box inside the house, with a relay that triggers 26 VAC to the rotor motors for each direction (clockwise, counter-clockwise, up, and down). For the radio hobbyist who may use it in their spare time there is no concern to the life of the relays inside. There is one little feature that changes the game here, a computer interface. Enter SatNOGS, an open source / open data community working to improve the amount of data collected from satellites ("cubesats") operating in the amateur radio frequencies. You don't have to know about the project to continue, just know that with a raspberry pi, the rotor is used day and night. Satellites move from horizon to horizon quickly, an overhead pass may take ~10-15 minutes. The rotor does not have to move constantly to keep up, but every few seconds it will make an adjustment. This constant ON / OFF cycle with 26 volts of AC across the contacts makes for a scenario in which relays will fail.

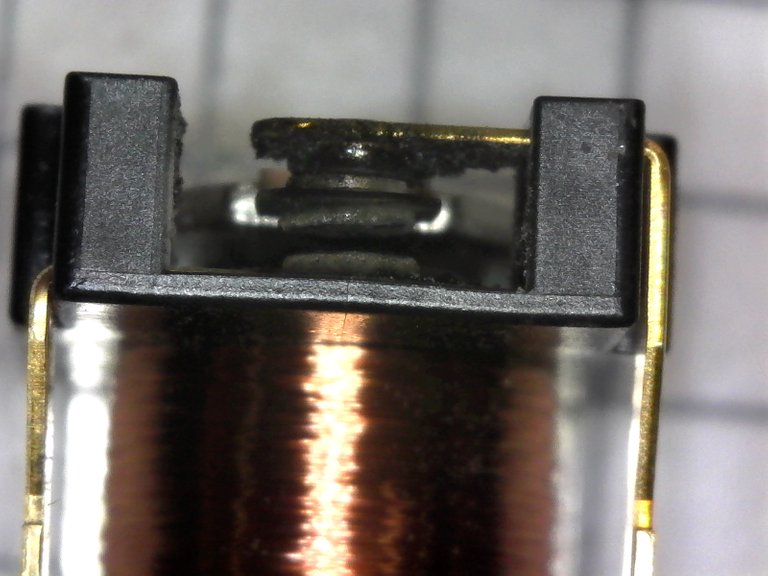

Here you can see some obvious damage to the relay on the left, and while the right relay looks somewhat okay we can see the wear clearly under a microscope.

This issue is referred to as contact wear, and the linked Wikipedia article does a good job of explaining further and talk about mitigating steps. The small electric arcing that occurs when the contacts close together and come apart causes damage and buildup on the contacts over time. In my case the relays could be heard in their failed state, the arcing caused a buzz while the relay was "stuck" in a closed position.

For my use case the solution is simple, replace the relays. Thankfully the controller box they are used in provided enough space for sockets to be installed instead of having to de-solder and re-solder relays every time they fail:

I've heard of ways to mitigate the electric arcing from happening in the first place. If you have experience here please share.

Cheers!

Interesting post! Welcome again, don't forget to make an #introduceyourself post introducing yourself to the community, and be sure to use the introduceyourself tag on it. Those posts with a moderate level of effort tend to do very well, and it a great way to get some engagement.

Thanks for the tip, will do soon!!

Congratulations @cshields! You have completed the following achievement on the Hive blockchain and have been rewarded with new badge(s) :

You can view your badges on your board And compare to others on the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPTo support your work, I also upvoted your post!

Do not miss the last post from @hivebuzz:

Support the HiveBuzz project. Vote for our proposal!