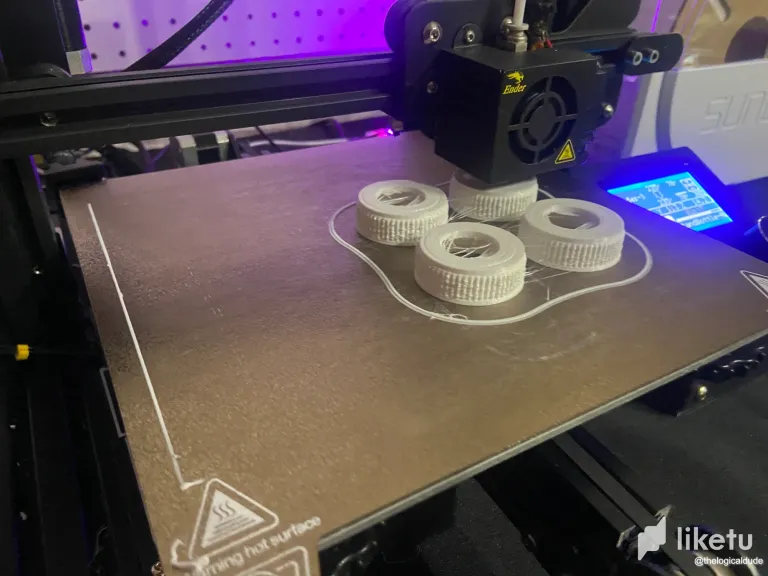

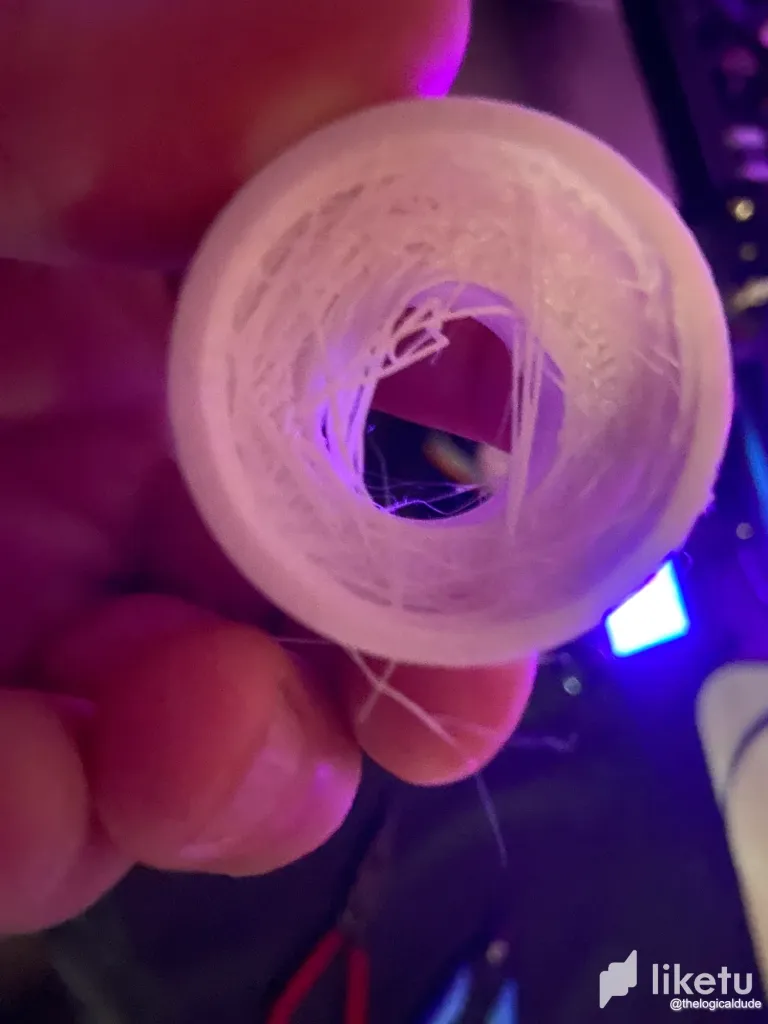

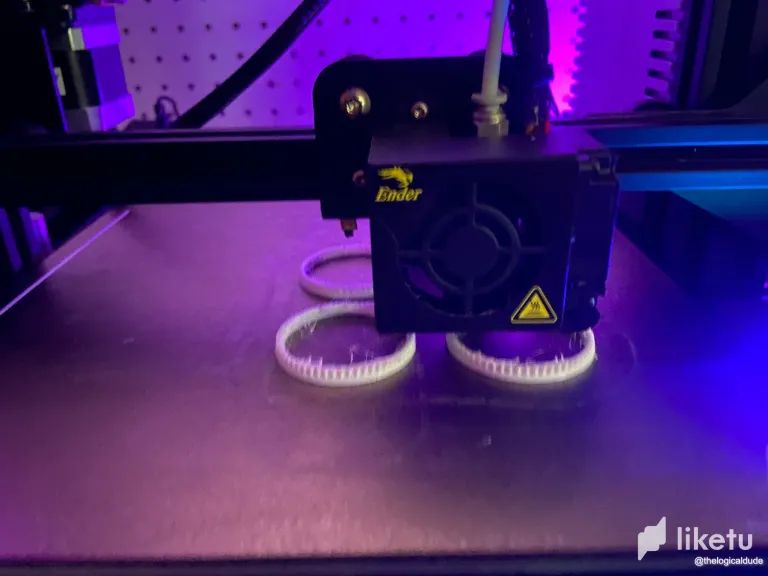

So the 3D printing journey I have found is much like anything else with a learning curve, you can run into problems that make you want to toss the machines out the window. In my case, I have been having issues lately with my plastic stringing. This means that it is either not setting correctly, or is putting out too much plastic when the print head is traveling causing hair like issues.

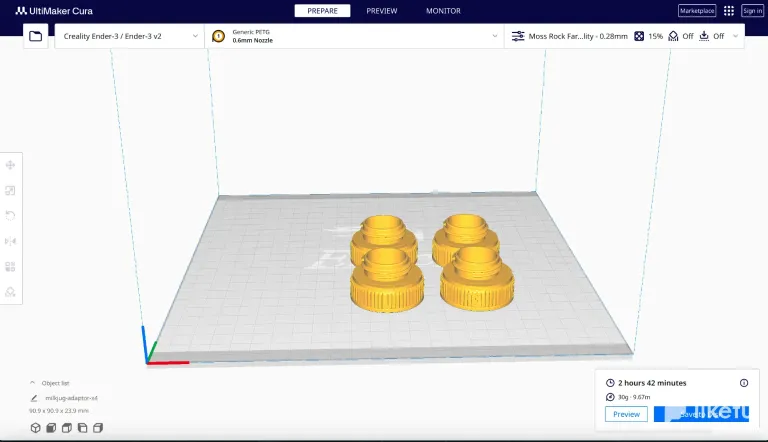

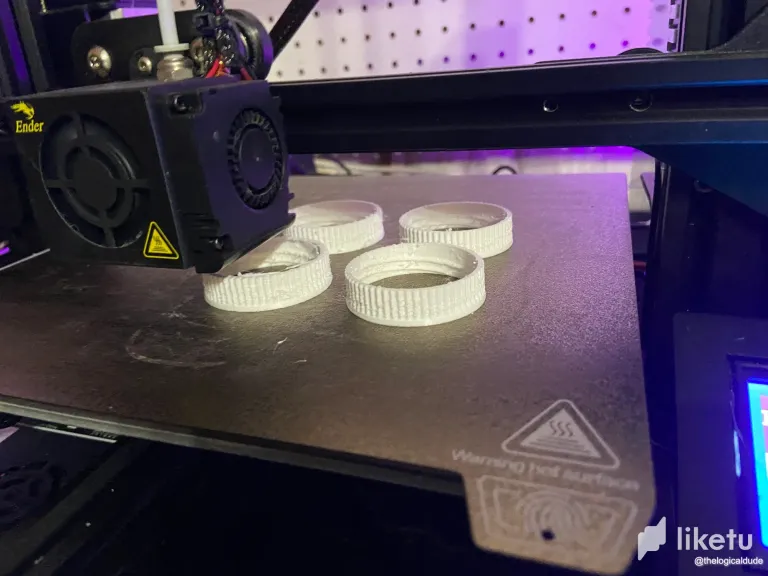

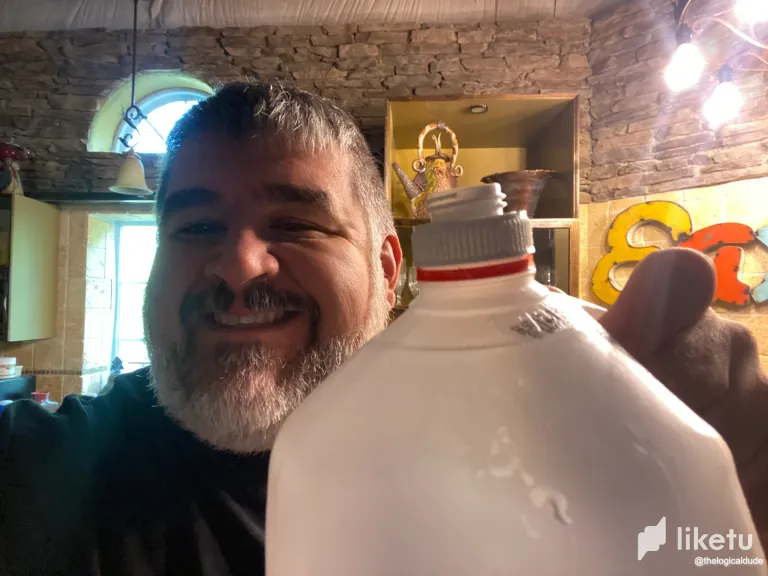

I am trying to make some milk jug to standard bottle adaptors for my chicken water bowls. The ones I printed and are using in Ft. Chicken are built to accept a standard bottle like a 20oz to a 2 liter bottle. Well, I need bigger bottles to keep me from having to refill almost every day. So I went onto Thingiverse.com and found a design that was exactly what I needed.

I seem to be having a bit of a setting issue that I am trying to solve, as well as a humitity issue. Living the the Southeastern US has it challenges when you have to keep your humidity under control. I bought the filament dryer boxes which was helping for a while, but with spring time coming in, along with higher temperatures, it's causing the humidity in the workshop to rise. So I need to do a bit of extra to get rid of these humid conditions. This might be making new boxes to store and use the filament in after it is dried out in the machines. My buddy has a design that uses some Rubbermade cereal containers and a bunch of silicon decedent to help keep the plastic dry while it prints. Right now, I am having to dry the plastic and then also run the boxes while prints are going on to keep it dry.

Regardless of it taking a few rounds of attempts to get this figured out, I finally ended up with what I was at least trying to make. They weren't perfect or anything near what I would consider 'production quality' that I would sell, but hey, they work for the task at hand, so I am happy! The whole point of these machines was really to make everything I needed on the homestead farm that I can out of plastic, haha. It's a part of my self-reliance journey that I am on. So learning everything I can out of every situation is vital so I am not wasting a bunch of the plastic filament I need to make the cool stuff I want to make. Eventually I want to get to where I am producing great quality, which might mean better machines in the future, so I can really turn this into a full scale business.

Until next time,

Be cool, be real, and always abide my dudes!

For the best experience view this post on Liketu

I have found that this is often due to not correctly measuring and entering your filament diameter. Filaments are not very uniform, and a difference of a few hundredths of an inch can cause over and under extrusion.

It’s a standard 1.75mm diameter filament. I am finding the main issue is temperature and humidity, at least in my case. But I will look into that.

Congratulations @thelogicaldude! You have completed the following achievement on the Hive blockchain And have been rewarded with New badge(s)

Your next payout target is 12000 HP.

The unit is Hive Power equivalent because post and comment rewards can be split into HP and HBD

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPCheck out our last posts: