Artificial Intelligence is the science that allows the creation of intelligent machines and systems that can reason and act in a similar way to a human.

Many philosophers and scientists studied human knowledge until they came up with a way to implement these capacities artificially, creating machines with intelligent functions. Development in the field continues extensively to the present day.

Machine Learning

It is an artificial intelligence technique that aims to create computational algorithms with the ability to learn patterns based on the information received to generate new knowledge and optimize the learning system.

It is currently applied in the fields of business intelligence and business decision-making, among other fields.

AI positively impacts the energy sector where decision-making is required to guarantee efficiency in the operation of processes and management of industrial assets through maintenance activities.

Implementation of the failure prediction model applied to an industrial gas turbine.

Data Understanding.

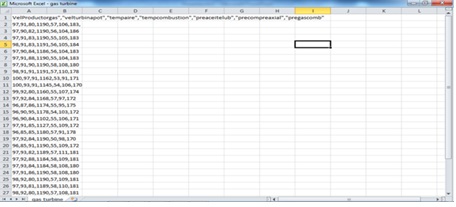

In this phase, the collection of initial data and its analysis are presented, to understand the structure, problems, solutions and achieve the optimal adaptation, in this case the data extracted from the daily reports and history stored in the local database was used. presented in Excel format, these coming from the different sensors in the field, which measure the operational variables through the automation of processes, which include sensors and communication networks.

Data Preparation.

The preparation of the data includes adaptation according to the modeling technique, data cleaning, discarding, generation of variables through (Feature engineering) and format changes were required. After this process, the data was integrated with the CSV structure (comma-separated file)

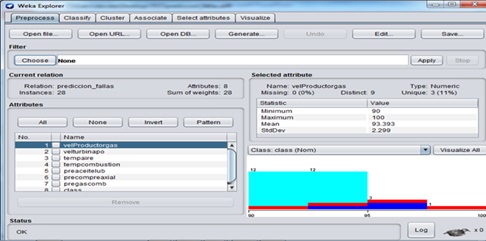

For modeling, the WEKA 3.8 tool, Waikato Environment for Knowledge Analysis, was used to apply the selected machine learning technique. This software is an environment for testing and experimenting with data analysis techniques, mainly automatic learning.

Data preprocessing

It allows to apply filters on the data, changes of attributes, instances, classes, discretization, reduction and transformation of the data. visualize the threshold values configured for the input variables of each neural network.

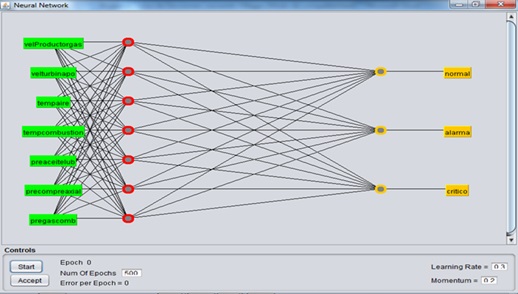

Application of the predictive model.

The design of the model was achieved by means of the supervised machine learning technique, with the use of a classification algorithm implemented by artificial neural networks, to predict the classes In this case of classification of failures with the labels NORMAL, ALARM, CRITICAL, which represent failure states to predict.

The classification shows 3 samples were classified for the ALARM state, and 21 samples in the CRITICAL state. This training represents the operating condition of a turbocompressor equipment and the criticality of the failures it presents, through this failure classification, actions are taken for the predictive maintenance of the equipment.