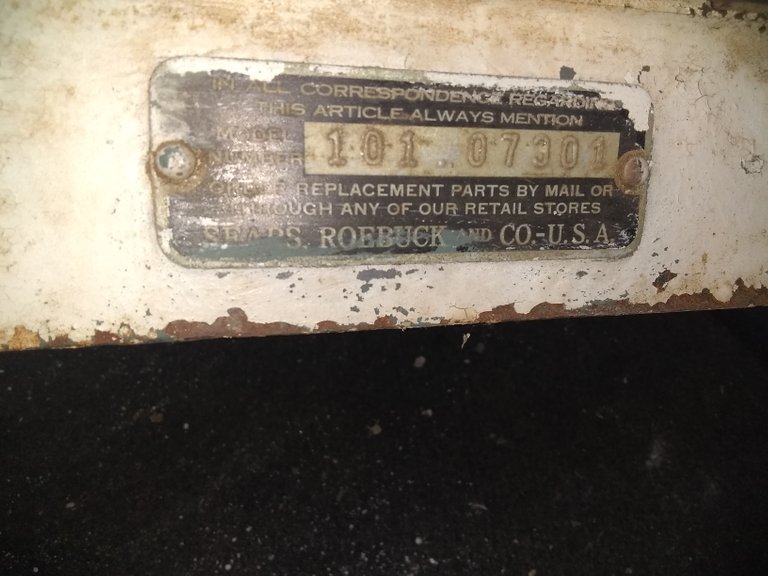

This past weekend, after the 2021 snowpocalypse, I went to help a fellow man scout move. Somewhere in the process he gave me this old Atlas Craftsman lathe that was sitting on his garbage bin.

It needs some love, but I've been wanting a lathe for a while, and building and cleaning the machine will give me a good opportunity to understand it's workings more intimately. Y'all know how I like to get hands-on with things.

First thing you can tell, if you know about such machines, is that it needs a drive motor, a chuck, and a tool holder. Thanks to more friends, some of those are headed my way. I have very limited knowledge on metal working machines, and no experience machining, so this is whole new ground for me.

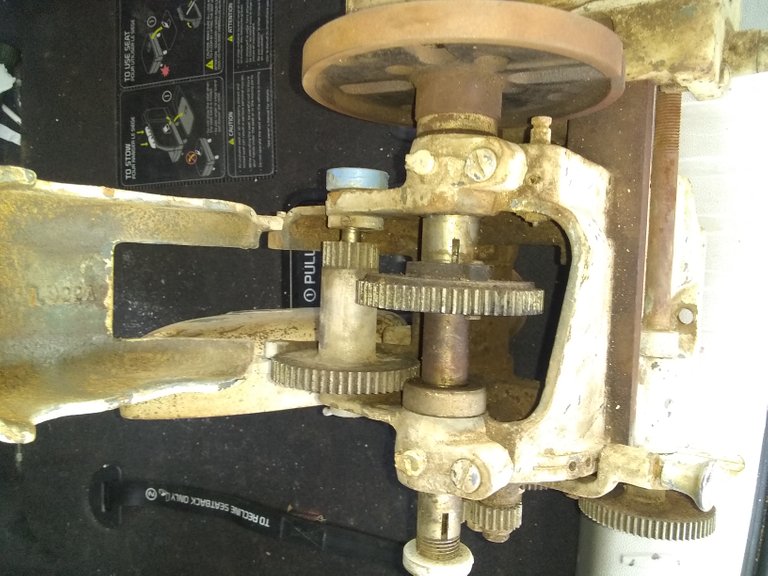

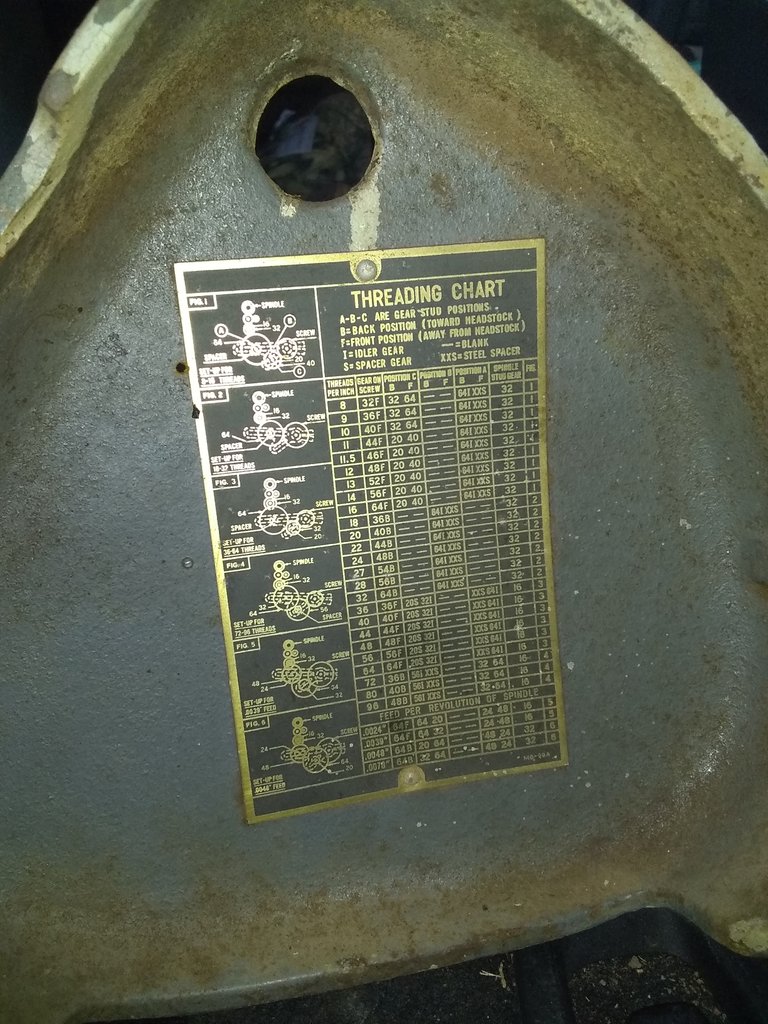

It's been a couple days, and I still haven't read enough to know my entire process and approach on this project. I'm still reading and learning, and I'll probably end up ordering a couple of lathe-specific books. So, while I'll still be needing filament to feed the printer, I'm shifting my constructive focus over to the lathe while the printer runs. I found out some of the gears are printable, so I'll no doubt be running some printed pieces on my restoration. I can tell by a few searches so far that this is going to be another expensive hobby lol

Thanks to community support, some folks are already giving me parts, advice, and direction towards the cause. It's making things easier and smoother by far. All these pictures will help me remember where everything goes when I reassemble it. So far, my plan is to take it all apart to clean it. Things that should move rather freely are gummed up from over half a century of grease, dust, and rust, so cleaning won't be a small task. I'm thinking a gallon of diesel and a wire brush. Maybe I should steal some gloves from work...

The paint, likely being from the 1950s, probably has lead on it. I don't know how that process will go at all, likely a respirator, some long sleeves, and a wire wheel on the grinder.

Another really awesome feature on these machines is the availability of a milling attachment. So in one small machine, you get a scaled down full-feature lathe and a basic mill. My mind is obviously racing with the capabilities and the products I'll be able to pump into my community with very little effort. And the side income ability that can also be reinvested to my community efforts. This is getting really exciting.

I've seen videos over the years of people doing really cool things with these types of machines. Supposedly, a lathe is one of the few machines that can be used exclusively to rebuild itself. I don't have any idea how or what I'd need, but cutting gears sounds really really fun.

Anyways. I'm rambling and probably boring y'all to death with my excitement here. I've been pecking away as work allows me to hash out a sentence or two on this post all week. Y'all get back to more important things than reading a silly post, and I'll go do more important things than writing one.

Spring is on the way, and I feel a WHOLE lot of energy building for this one. I'm praying to be able to channel that into a whole new level of radical progress in the chapters that'll unfold this year.

Love from Texas,

Mate 💚

Very cool! My husband had a couple lathes out in his shop. They probably need work now too, but....

I keep thinking of my father in law and how much he'd love this project. I'm looking through one of his old books to learn a bit, it's got his name in engineer all caps perfect lines, and what I assume was his clock number when he worked at Boeing.

How are you doing up there?

Lumping along, as usual. Good days, bad days. Feb. 25 was the 2 month anniversary, so not a good day...

But the carpenter is making great inroads here and I'm pleased with his work, as I think my husband would be.

It's a beauty, Enjoy!

The possibilities with a mill and a lathe are endless. I grew up working in a machine shop as a kid, and even was able to take college courses for machine trades in highschool for free, but never pursued it as a career. Good luck with this project, certainly looks like it needs some love.

Luckily they used to overengineer these old machines, and that means they last forever with a little love.