I have been running ideas through my head for a while about building a heavy duty workbench. One that is mobile, can hand some serious weight, something I can really beat on stuff with, has a vice mount, half of the top steel and the other half wood, and the majority of it made from parts and pieces used to to build Powerlines. Used parts and pieces of course, stuff that normally gets recycled or thrown in the dumpster. A little Lineman Up-cycle if you will.

After a little garage cleaning my son (@w-splatts) and I got to work building the beast of a bench. The bottom frame portion is going to be a shelf and it needs support in the middle. These old V-braces should work great to span from side to side. Then I plan on covering it with expanded metal. Basically these V-braces will determine the size of the bench.

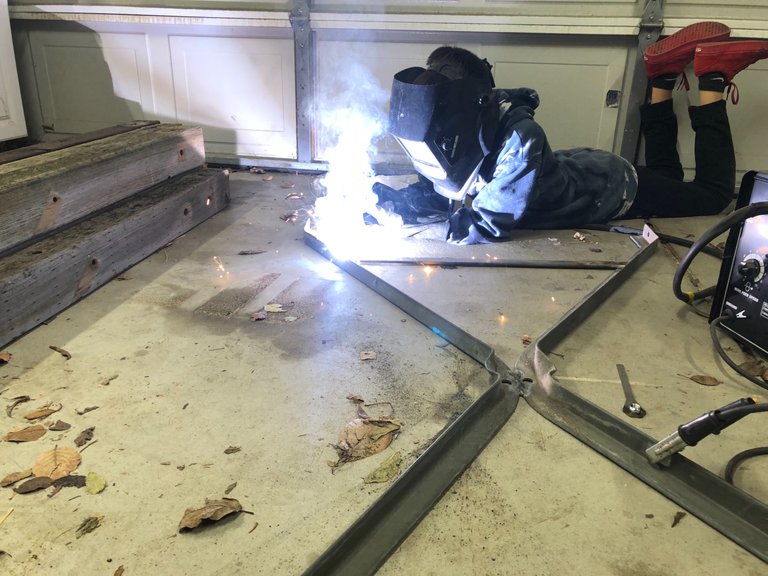

After squaring them up and evening up the ends, it’s welding time. First the bottom portion of the V was welded, then we added some straight braces to add some support.

We may add a couple more but I think this will do for now. After a couple test runs, his welds look better than mine. I better get to practicing!! Either that or this kid might just turn out to be a welder.

I did tell him to get comfortable...

With a little welding out of the way, this sort of sub frame is compete... for now. We may have modifications to make in the future. This bench is a going to be a little trial and error. We put our heads together for a basic concept but it’s gonna involve a lot of changes.

We figured a height of 36 inches would be good, then add in the height of the casters... should be about 42 inches tall. Being able to wheel this out of the garage with a bunch of tools on it will be really nice. The length is 66 inches and the width is 44 inches. The lower frame will sit off the ground about 12 inches and bolt to the legs and steel frame we built.

I really want to make these legs as stable as possible. Bolting them to each side of the lower frame should keep them from moving in either direction. 90 degrees of each other.

We made some good progress and it only took a couple hours. I need to do some digging in the scrap bin and see if I can find any other brackets and stuff that I could use. I need to get some old nuts and bolts that’s for sure.

The plan is to build the top next then start bolting everything together. The top going to be really heavy I know that. I need 10 more cross arms!! Holy Crap!! Glad we have a nice stock pile at the shop. 😜😜. I want to add a power strip for plugging in chargers, and some other stuff to make this table ready to work on anything.

Your Random

Dose of...

Congratulations @splatts! You have completed the following achievement on the Hive blockchain and have been rewarded with new badge(s) :

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPDo not miss the last post from @hivebuzz: