Textile Printing is a process of decorating textile materials by use of dyes/pigments of different colors to make particular impression in the fabric. Textile industries use different systems to print the fabric. Like screen printing process, flat bed printing process, rotary printing process etc.

For print a fabric, the fabric should have go through some other process. Because for uniform print & for obtain desired result a fabric should have prepare fast. Also after printing there are also some processes.

Greige Fabric/Gery Fabric

Today I will talk about the process should should have done to print a textile material/fabric. Grey fabric (Woven/knit) is a raw material for printing. Here grey fabric is produced by weaving / knitting.

Singeing & Desizing Machine

Firstly Singeing & Desizing is done to remove the size materials and also projectile fibre from the fabric. Size materials add into warp yarn for better weaving.

Batcher Rotation

After Desizing the output batcher which contained grey fabric is rotated for 6/8 hours so that the desize chemicals can work properly.

Scouring & Bleaching Machine

Secondly, Those singed & desized fabrics (Woven) go through scouring bleaching process. In this process dirt, dust, oil and other impurities are remove here. Those impurities can be natural or added.

Also natural color is removed from the fabric which helps to get more white fabric.

Mercerizing Machine

Mercerization process is for cotton fabric to improve their lusture by changing its shape. After passing this process the fabric looks more bright which helps to proper printing.

After Mercerization fabric is prepared for printing in a stenter machine which is mainly known for Ready for Printing.

Flat bed Printing Machine

Here in this machine fabric is printed according to design by using screen. The screen is flat in this machine.

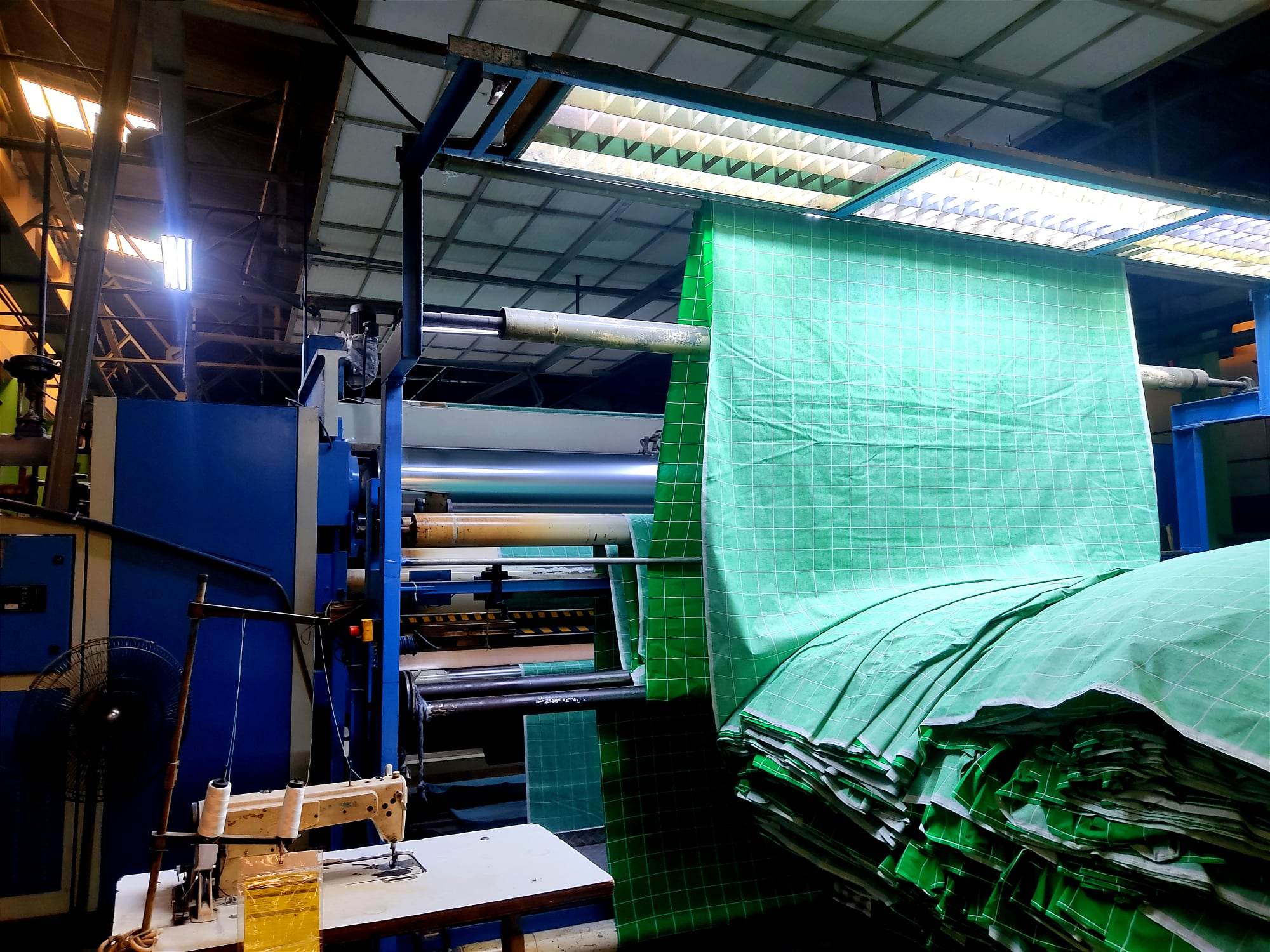

Rotary Printing Machine

This is also a printing machine. Which known rotary printing machine. This machine is most popular printing machine due to it's high speed print capacity.

Washing Machine

After printing at printing machine the fabric is go though curing machine. Curing is a process of fixing the color on the fabric. Then washing machine is used to remove unfix colors.

Celendaring Machine

Calendering is a process of improving hand feel of printed fabric. After this process fabric feels softer.

Sanforizing Machine

This is the last proces of fabric processing. In sanforizing machine fabric shrinkage is controlled. After passing this step now fabric is ready to deliver for the other process.

Hi @fa-him, your post has been upvoted by @bdcommunity courtesy of @rem-steem!

Support us by voting as a Hive Witness and/or by delegating HIVE POWER.

JOIN US ON

Learning about the overall printing process, especially for textiles, really shows how much detail goes into making a final product look good. Whether it’s colors, alignment, or materials, small mistakes can be annoying. That’s why having reliable support matters when using services like https://snapfish.pissedconsumer.com/customer-service.html Knowing how to contact their page is handy if an order has issues or doesn’t turn out as expected. Seeing real experiences from other customers helps set expectations. Good support can really turn a potentially stressful printing experience into something smooth and hassle-free.