I installed two 50 amp breakers in a commercial panel, and the job turned into a textbook case of precision planning and solid execution—right down to the last knockout.

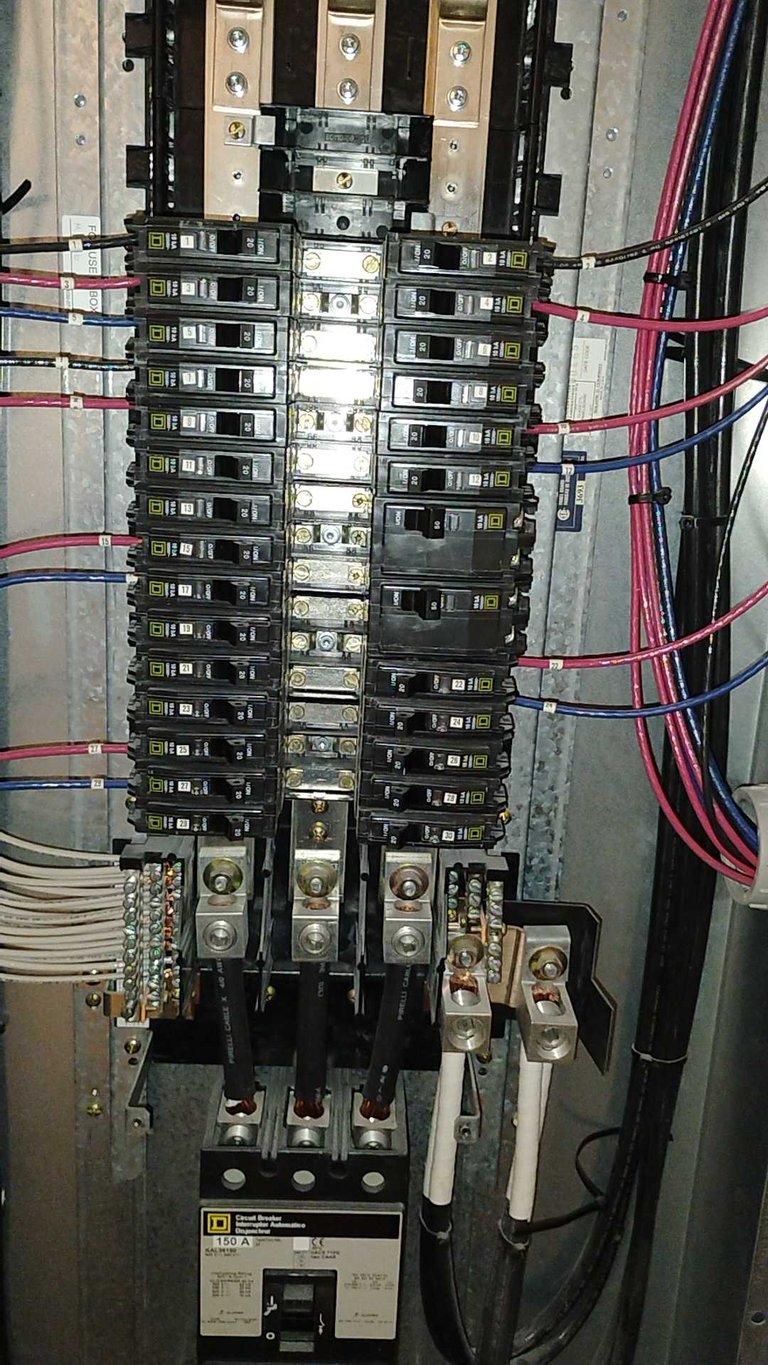

The panel was a Square D QO series, with clean room for expansion. First thing was confirming that it could accept two more double-pole 50 amp breakers without disrupting phase balance or code compliance. After confirming that, I used a step bit to punch clean 7/8" holes in the top plate for my conduit entries. You can see in the image how neatly they lined up—critical when space is tight and the run has to be clean.

I used 3/4" Greenfield (flexible metal conduit) from the panel to the equipment junction points. Greenfield was perfect here due to the tight bends and mechanical protection needed through the ceiling cavities.

Inside the flex, I pulled 6/2 MC cable. While not the most fun cable to work with, it’s solid for 50 amp loads and handles motor loads or resistance heating easily. I made sure to leave ample length for stress relief and secure clamping—no pinched insulation or unsupported lengths.

Breaker install was straightforward—torque specs met, wires neatly terminated, and everything tested clean. I finished with proper labeling in the panel, and everything powered up perfectly.

This report was published via Actifit app (Android | iOS). Check out the original version here on actifit.io