The Sea Axe: Ship Design & Construction Project

Ship Design & Construction is a second year subject, it is a bit lay back and the intention is to familiarise ourselves with different industry CAD software, scale model making, construction techniques and general terminology.

Our Major project is to choose a vessel and make a scale model, it is a group assignment, I'm guessing to save on materials, and our group are dedicated and capable so we are cruising through most of it, which is a great break from our other subjects. The vessel we have chosen is the Damen Sea Axe 5009

The Sea Axe class name comes from the shape of the bow which is similar to an axe shape. To the left you can see a photo showing the unique hull shape at the bow. While we were able to obtain some dimensions, profile and plan drawings, this is not enough to properly shape the hull curves. Therefore we gathered as many photos as possible of the vessel out of the water and designed the hull as best we could.

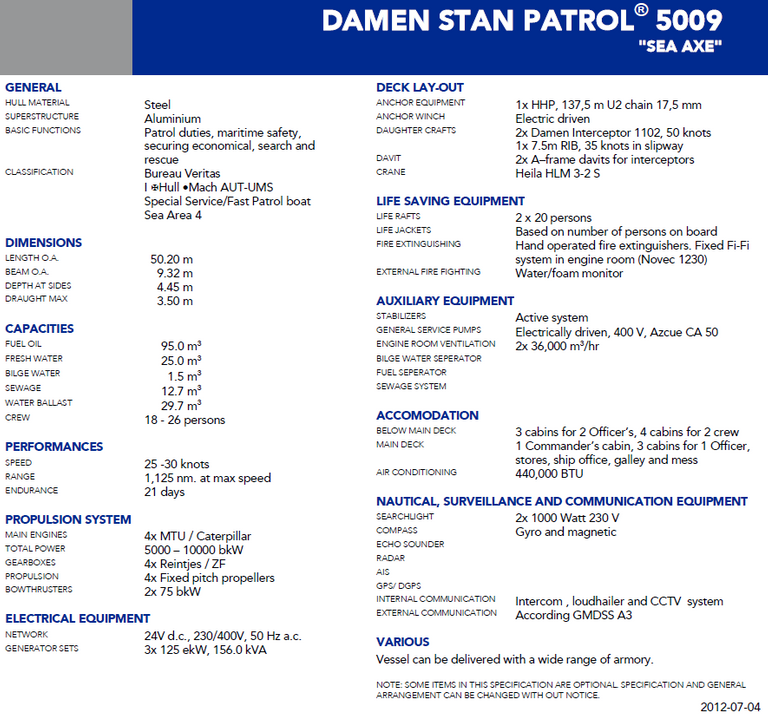

The Vessel Particulars

The above ship particulars were obtained from the Damen website on their specification sheet. The vessel is designed for superior sea keeping performance at high speeds. The long slender hull provides exceptionally low resistance, delivering excellent fuel efficiency at all speeds.

Vessel In Action

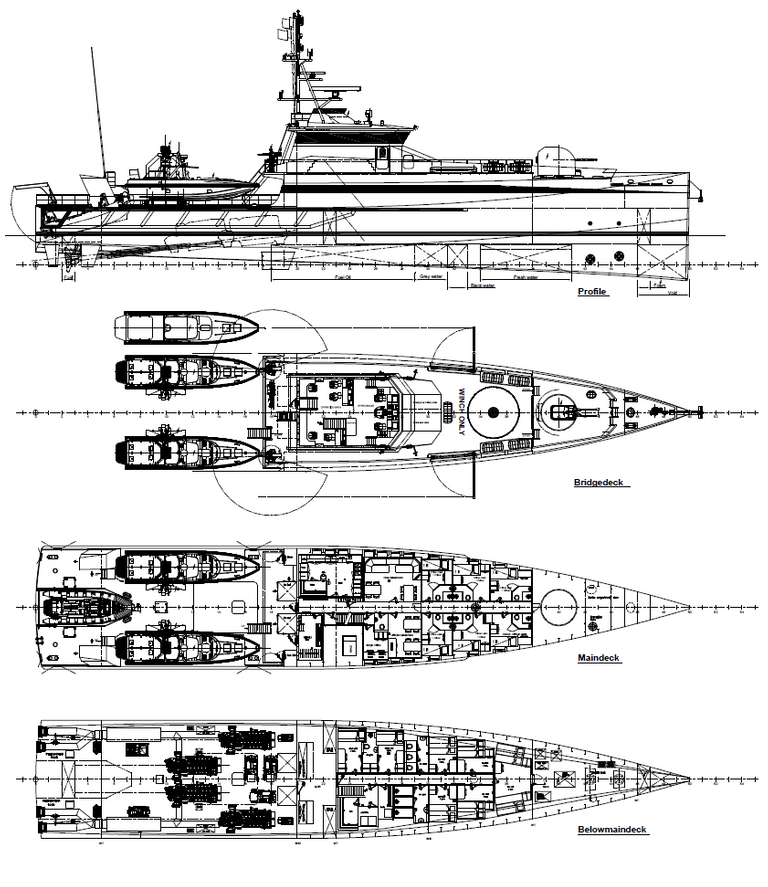

The Profile & Plan Drawings

The drawings are the promotional drawings from Damen. From these we will be developing a CAD model which will include our design for the beams, framing, webbing and safety bulk head compartments required to construct the model. The model is to be scale in dimensions and displacement, meaning we will be adding a additional weight to bring it to the correct displacement. This happens because our construction material density does not scale down to the density of steel used in the full scale vessel (there is some guess work required here). If we were doing real tests, we would probably making larger models to be more accurate in construction.

General Procedure

- Choose Vessel

- Develop CAD Model

- Arrange model frame and parts for laser cutting

- Check & assemble frame

- Sheet and strip plank frame

- Seal, perform fairing & coat

- Test in the Test Basin (AMC Test Basin Pictured)

Model Scale

Scale 1:60Vessel Length: 50.2m

Model Length: 0.836m [836mm]

Next Post: CAD Modelling

The following post will be about the development of the CAD Model and preparation of the parts sheet for laser cutting. If you are interested come back and check on our progress through the post project.

My Current Quotes

I have never understood why it is "greed" to want to keep the money you have earned but not greed to want to take somebody else's money.

Thomas Sowell

I chose this quote as I like Thomas Sowell and I have been thinking lately on the fairness of how the proceeds of our labour are spent, he also said:

Helping those who have been struck by unforeseeable misfortunes is fundamentally different from making dependency a way of life.

Thomas Sowell

Thanks for stopping by and having a read

Looks like a really fun project! I really enjoyed looking at the drawings and learning how the space gets used on a ship like this one.

Yeah it is actually a lot of fun compared to the other subjects we are doing. The next posts will be in short succession as we have progressed since there. Come back and check out the CAD stuff next.

I will make sure I come back to check it out indeed :)

Gday,

Mate we have progressed a bit, if you are keen for a look.

https://steemit.com/technology/@rezantroy/part-1-introducing-the-sea-axe-5009

https://steemit.com/teamaustralia/@rezantroy/part-2-cad-modelling-the-sea-axe-5009

https://steemit.com/teamaustralia/@rezantroy/part-3-part-1-introducing-the-sea-axe-5009

https://steemit.com/steemstem/@rezantroy/part-4-strip-planking-and-sheeting-the-sea-axe-5009

Yeah Awesome project, looks like fun

yeah it is fun, thanks. Check out my next posts, for the CAD drawings

cool! cant wait to see the compleated vassel 😀

Congratulations @rezantroy! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOP