How are you, architectural design friends?This week I am back again in an interesting publication about architectural design furniture which is part of my daily work and this week I am back again in the publication of architecture + home window furniture design and this is the 3rd edition of the architectural publication + house window design with a different design from the window designs that I have published before.

In rural areas, in general, people construct house buildings on a one-time basis and they will occupy it for life and basically every homeowner usually builds a house with a fairly simple design, both wooden houses and concrete houses, as well as house windows,, in general, homeowners sometimes like to make attractive window designs so that they will present an eye-catching feel of beauty and each design has a different color of beauty as well as the wooden window design project that I just finished this week.

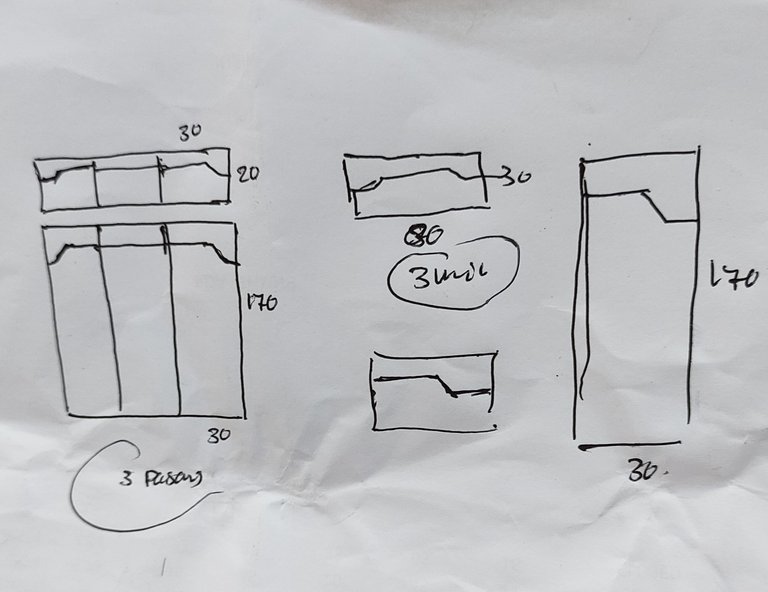

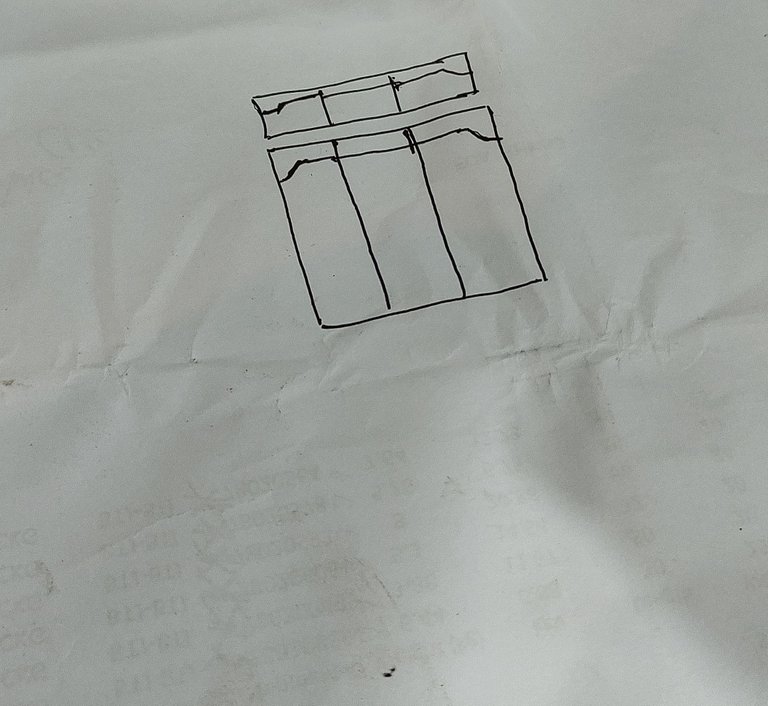

The window design that I just worked on does look a little unique and contains a different distinctive beauty, here you can see the image design display of the window and door jalousie in one package which is reserved by the villagers.

In this one order package, consists of 9 windows measuring 30cm x 170 cm, 9 units of window jalousie measuring 30cm x 20cm and 3 units of door jalousie measuring 20cm x 80cm.

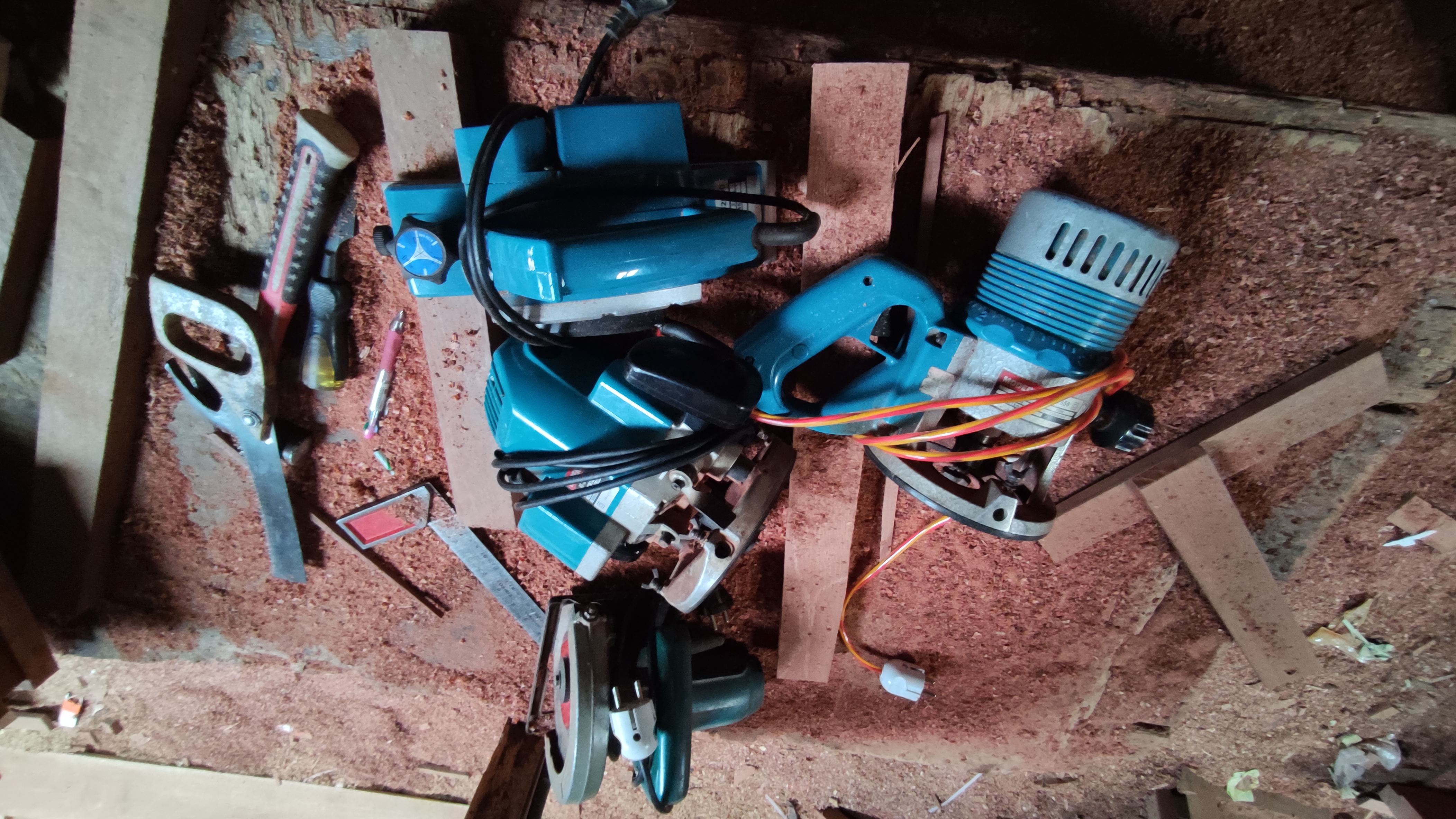

The customer orders the order package, which is made from meranti wood with 5mm black glass and to complete the project, here I use the machine tools that I use as usual, namely.

Wood cutting machines, shaving machines, router machines, sit drills, chisels, hammers, mini hand drills and manual presses and also a seat panel machine for making window series peg nipples and the meranti wood beams for the window series that have been trimmed with a size of 6cm x 200 cm I cut for all the window and jalousie series materials for the left and right poles and bulkheads at the top and bottom of the window.

The windows consist of 9 units with a window height of 170 cm, followed by 9 jalousie units with a height of 20 cm and a door jalousie with 3 units of a door with a height of 20 cm.

9 units of the left and right pillars of the window measuring 170cm and I cut the wood with a size of 175cm, the rest I added 2.5cm up and 2.5cm down so that the wood doesn't break during the process of installing the pegs.

•18 wooden poles for the main left and right windows with a size of 175 cm high, 6 cm wide and 3.5 cm thick.

• 24 The main bulkhead 9 units of window jalousie and 3 units of door jalousie with a height of 20 cm.

And for the upper and lower bulkheads of the window and the jalousie here are slightly different (note the order design picture) with the same length and to get the correct size on the upper and lower bulkheads of the window,I reduced the width of the main partition on the left and right of the window, namely 6cm + 6cm(left-right) = 12cm and the order of the window is 30cm which means to get the right size on the top and bottom of the window 30cm-12cm + 6 cm for the peg nipple = 24cm and I need wood for the upper and lower bulkheads of the window to see as many as 24 units of the bulkhead which was followed by 12 units of the upper bulkhead that had formed a mereng angle with a machine sitting jidsaw and after the process was complete then I continued the process of drilling the peg holder on the main bulkhead of the window and julusi.

I have finished a series of main materials and now I continue the process of making the nipples of the pegs on the main wood of the upper and lower bulkheads of the window and the manufacturing process I do using a panel machine and this is how the process looks.

After the process of making the peg nipple is complete, then I continue the process of unifying the entire series starting from a series of windows, door jalousies, to window louvers and , process goes like this.

And after the main series unification process is complete, the result will look like this and the window layout design starts to look so beautiful.

Now I continue the process of planing or smoothing all the front and back surfaces of the window and the bulkhead to make it more tidy and the result of the window will look like this after I trim it using a hand shaver machine.

And now I continue by giving flowers on the inner surface of the left and right windows, so that the window looks more beautiful and also I continue the process of scratching the 5mm glass hole holder on the inside of the window with a depth of 1cm and in this process I use a hand router machine and after the process is complete, the window and jalousie will look like this.

And now the process of making the main series of windows and all the jalousies is complete, then the process of cutting the 5mm black glass and installing the glass for all that windows and jalousies.

In the glass cutting system, for windows and jalousies that have a shape design, here I cut a hollow shape following the mall of each window and in this process I am careful enough so that the glass does not break when cutting and at the time of installation, so that the glass installation process is easier, at the time of installation I opened half that main series of windows,

And after I finished installing all the glass on the windows and jalousies, then I continued the process of pressing and locking the corners of the main bulkhead connection with the upper and lower bulkheads of the window using wooden pegs and in the process of inserting the bulkhead key here, first after I press with iron , I drilled using a hand drill to make a key hole peg holder measuring 1cm.

When finished, I locked all the bulkhead joints, then I continued the process of applying a little dumpling to the bulkhead and the dumpling was the glue that I mixed with sawdust, and the whole process was like this.

After the pressing process and the locking of the connection angles were completed I did ,now I have to wait a while until the dumpul glue dries because for the process of finishing the project, it is smoothing by rubbing the entire front and back surface of the window to make it really smooth with using a sanding machine.

And after the smoothing process is complete I work on it ,, 9 units of window 30cm x170 cm, 9 units of window jalousie 20cm x30cm and 3 units of jalousie 20 x 80 cm , finished I working on and in total all the projects were 21 units consisting of door jalousie, window jalousie and window which is owned by the villagers and this is the result of architectural+design finishing window and jalousie made of meranti wood with 5mm black glass from process to completion.

And according to the order, they will install the windows in a set consisting of 3 window frames and 3 jalousie and the wood from the bulkhead 2.5 cm up and down will be cut by the house builder when the windows will be installed and painting is also done by the house builder in accordance with the color desired by the homeowner.

All of these pictures I take when i was working on that window and jalousie project ,all images were taken using a smartphone camera, if you want to enjoy my previous architectural design works, please visit the post link below.

All of these pictures when i was working on that window and jalousie project ,all images were taken using a smartphone camera, if you want to enjoy my previous architectural design works, please visit the post link below.

1.Architectural design- simple cafe bar table

2.Architectural design - Wooden tray with natural wood color combination/utilization of wood waste

3.Architectural design - Flower vases / utilization of wood waste.

4.Architectural design-Simple architectural design of my baby crib basket.

5.Architectural design-Table simple the combination of natural wood colors and classic table tops

6.Architectural design- Shophouse frame jalousie

7.simple-minimalist-mini-wall-shelf-architectural-design-to-decorate-your-home-room

8.architectural-design-of-the-ventilation-jalousie - part 1

9.architectural-design-of-windows-house -part 1

10.interior-design-architecture-simple-makeup-mirror-frame.

11.architectural-design-simple-minimalist-wooden-window -part 2

12.architectural-design-window-designs-that-are-in-great-demand-by-local-residents

13.architectural-design-of-a-mini-table-and-a-simple-photo-frame

The rewards earned on this comment will go directly to the person sharing the post on Twitter as long as they are registered with @poshtoken. Sign up at https://hiveposh.com.

You never failed to impress me, my friend. Good evening!

good evening again friends, as usual this is part of my daily activities and you can also see a video of the results of these windows here.

Oh, thank you for the video, my friend. Good evening!

good job!

thank you @urun and my greetings @deltasteem from Indonesia.

Hello, friend @deltasteem. These architectural windows pretty much look different from your previous woodworking productions. They apparently resemble vertical slit windows due to their elongated shape with a small width and long height. Are those black glass panels prefabricated already when you ordered them from the supplier?

hello also my brother @storyoferne for densain this window is only located at the top vertical corner and this is one of the designs that I rarely work on in different size scales and the window with a width that looks small and elongated is a window model that is well known to modern society today, and some customers sometimes often take this size with a plain tile display design in black, clear and green glass.

Great, thank you for the informative feedback. Kind regards @deltasteem! 😊

you're welcome @storiesoferne we are still enthusiastic about this 😊

Congratulations @deltasteem! We're delighted to specially curate your awesome publication and award it RUNNER-UP in Architecture Brew #64. More power!

Thank you for subscribing to Architecture+Design, an OCD incubated community on the Hive blockchain.