How are you all architectural + design hiveans friends,greetings in the month of May and last week a few days before entering the Eid holiday ,, Mr. Marhaban came to my CV work and asked me for help to repair the door of the shophouse, which had not been repaired for a long time due to economic factors . .

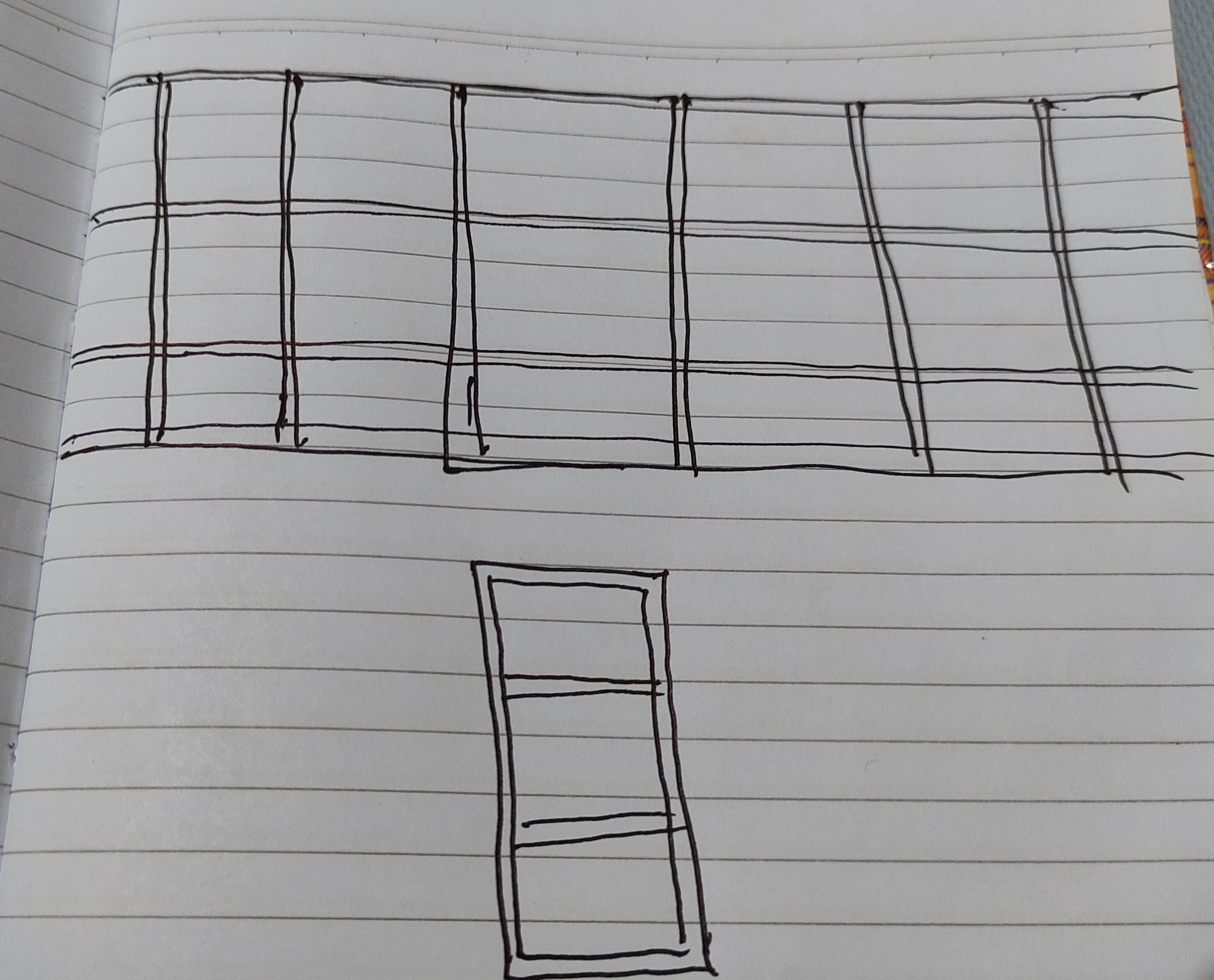

Mr. Marhaban came to my CV Furniture asking for help to finish the folding door of his shophouse while bringing a door design that looks so simple.

and after I saw the door design drawings, I compromised with him about the type of wood he wanted to complete the door project and he asked for a simple package shop door design with 12mm multiplex doors which the price is relatively cheap.

And this can be said to be one of the cheapest shop doors and is often used by local people.

The next day I went down to the shophouse location to measure the width and height of the door and after my measure the square area of that shop door,I went back to my CV and prepared the materials to complete the project and the customer also asked me to complete the project until the door installation stage is complete and ready to use.

That shop door measures 400cm wide and 240cm high.

For cheap shop door packages made of 12mm multiplex door leaf sheets, one package consisting of 9 or 10 doors, we usually use a series of frame structures made of boards.

The equipment I need to complete that door.

• Plywood sheet as a door leaf

• Boards for door bones

• 2 inch nails

• Door hinges

• Screw bolts to fasten hinges

• Wood cutting machines

• Electric drills

• Hammers and

• Elbows.

And the basic size of the shophouse door frame that has been installed in the shophouse of Pak Marhaban's workshop is 400cm X 245 cm and this is the size of the permanent door frame of the shophouse door.

Each sheet of multiplex usually consists of a width of 122cm X 240cm and the door of the shop consists of a size of 400cm x 240cm so that the multiplex is not wasted and is not wrong in the cutting system and here we use the formula , ×, + , - and to get the right size and number of folding door units made of multiplex sheets for the shop, it is.

•First, I divided the width of the multiplex into 3 parts with a cutting system lengthwise upwards, meaning 122 cut 3 and after multiplex I cut the size into 40cm wide x 240cm high and the multiplex after being cut wasted 2cm. for the height of the plywood I cut 4cm because plywood is the basic size of the door and the plywood sheet is the base size of the door, which is 40cm x 240cm

After the division of the multiplex was completed and of course I got the size of the folding door 40 cm x 8 leaf = 320cm and 1 units measuring 80cm.

For the door frame or bone, here I use a pine wood plank which I split into 3 parts.

After processing the frame material, the door frame has a width of 6 cm and a thickness of 2 cm and I continue the process of cutting the corner posts for the left and right, top and bottom and the middle bulkhead of the door and the total bulkhead that I have to cut for 8 door units measuring 40cm x240cm and 80cm x 240 cm is.

• 18 bulkheads 240cm long consisting of left and right bones for the 9 doors with a wooden end system mereng inward at the top and bottom of the main pole.

•16 Upper and lower door bulkhead unit with bereng end cutting system with a length of 40 cm for the main door bulkhead, the width of the top and bottom of the door.

•16 units of the middle door divider measuring 28 cm for the 8 units of the door.

And for a door width of 80cm 1 unit, the total length of the bulkhead that I have to cut is.

• 2 bulkhead unit door width up and down 80cm.

• 2 bulkhead 68cm door center bulkhead units and this is the shape of the main bulkhead of the pine board after I finished collecting it before I assembled all the doors.

And now we enter the door assembly process and here I use a series of bulkhead paste systems on the plywood sheet that I have provided with the right size for the height and width of the door.

• plywood sheet (door size) 40 cm and 240 cm high that I have provided, first I provide insulation on the left and right parts of the plywood sheet by using a nail system.

After the installation of the main left and right bulkhead poles was completed, then I continued the process of installing the upper and lower wide bulkheads of the door and the attachment system of the circuit also using nails.

Then after the process of unifying the main series of bulkheads was completed, I continued the process of giving the middle door bulkhead so that the plywood door was strong and durable and produced a beautiful design from these bulkheads and this is how the door looks like after I finished working on it in one unit with a size of 40cm x 240 cm.

And this is how the architectural appearance of the door looks and I have to finish 8 units of doors with the same width, which is 40cm x 240cm, while one unit of 80cm x240cm I finished at the end of the manufacture because they have different sizes.

After I finished the work on the 9-door unit, I trimmed the entire width and height of the surface using a shaving machine so that when installing the door it was really neat.

and for the process of unifying all the doors with a folding system here I use ensex and screw because the door is quite light and in one door the customer asked me to just install 2 ensels in the middle of the door even though I know the maximum is 4 ensels and 2 ensels are not optimal for that door and and i forced do it according to customer's request.

I did the assembly of the door installation simultaneously at the location next to the shophouse and the process of installing all the hinges was quite fast with the help of screw fastening bolts and an electric screwdriver drill.

and for the main ensel of the door fastener series on the permanent frame series, the customer also asked me to give 2 ensel and this is not the maximum number for the shop door ensel even though we use cheap shophouse doors both long term and short term because the maximum size in 1 sheet of door is 4 ensel.

After the process of binding the main series hinge for each door, I divided the door into two parts, namely 4 left-open units and 5 right-open units consisting of 1 large door unit as the main door for the shophouse.

And for the sheet door that I have installed the ensel on, I lift it up to the frame rail for the workshop door frame holder and I continue the process of fastening it to the shop door frame series and after the next door is installed this is how it looks.

a simple shop door looks so beautiful then I continue the process of installing 4 doors on the right and after the installation process is complete all the motorbike shop doors look like this and the doors are made of 12mm multiplex pine wood frame with a total of 8 doors measuring 40cm x 240 cm and 1 the center door unit measures 80cm x 240cm and here you can also see some pictures of the process of making the door in some pictures.

This is the door project for Mr. Marhaban's motorbike repair shop that I finished working on in the last few days last week before Eid al-Fitr.

All of these pictures I take when i was working on that doors and all images were taken using a smartphone camera, if you want to enjoy my previous architectural design works, please visit the post link below.

All of these pictures when i was working on that window and jalousie project ,all images were taken using a smartphone camera, if you want to enjoy my previous architectural design works, please visit the post link below.

1.Architectural design- simple cafe bar table

2.Architectural design - Wooden tray with natural wood color combination/utilization of wood waste

3.Architectural design - Flower vases / utilization of wood waste.

4.Architectural design-Simple architectural design of my baby crib basket.

5.Architectural design-Table simple the combination of natural wood colors and classic table tops

6.Architectural design- Shophouse frame jalousie

7.simple-minimalist-mini-wall-shelf-architectural-design-to-decorate-your-home-room

8.architectural-design-of-the-ventilation-jalousie - part 1

9.architectural-design-of-windows-house -part 1

10.interior-design-architecture-simple-makeup-mirror-frame.

11.architectural-design-simple-minimalist-wooden-window -part 2

12.architectural-design-window-designs-that-are-in-great-demand-by-local-residents

13.architectural-design-of-a-mini-table-and-a-simple-photo-frame

14.architecturaldesign-of-glass-windows-and-jalousies - house

15.architecture + door design of local people's houses.

Congratulations @deltasteem! We're delighted to specially curate your awesome publication and award it RUNNER-UP in Architecture Brew #67. More power!

Thank you for subscribing to Architecture+Design, an OCD incubated community on the Hive Blockchain.

thanks @aplusd and I hope the team working is always healthy there :)

Always with great pleasure dear @deltasteem. Keep it up! 😀

The rewards earned on this comment will go directly to the person sharing the post on Twitter as long as they are registered with @poshtoken. Sign up at https://hiveposh.com.

Thank you for sharing this amazing post on HIVE!

Your content got selected by our fellow curator @priyanarc & you just received a little thank you via an upvote from our non-profit curation initiative!

You will be featured in one of our recurring curation compilations and on our pinterest boards! Both are aiming to offer you a stage to widen your audience within and outside of the DIY scene of hive.

Join the official DIYHub community on HIVE and show us more of your amazing work and feel free to connect with us and other DIYers via our discord server: https://discord.gg/mY5uCfQ !

If you want to support our goal to motivate other DIY/art/music/homesteading/... creators just delegate to us and earn 100% of your curation rewards!

Stay creative & hive on!

thanks @priyanarc My greetings to you and your family, I hope you are always healthy there and thanks @diyhub I hope the team working there is always healthy ;)

These are really quite a great work you done here with the lots of pictures to back it up. You must be good in the furniture work you did which is also good to see

thank you and greetings and furniture is part of my daily work and all furniture publications are orders from local customers :)