Greetings architecture + furniture design, this is the month I was born and as time goes by I can't believe I am now 30 years old and yesterday was my birthday and I have been working in furniture for 10 years.

I @deltasteem my daily activities as a furniture worker and I am very grateful to mod @storiesoferne and @aplusd for opening the architecture+design community as our place to publish various kinds of architectural+design publications and here every week I am only in the publication of architectural + design furniture which is the result of my work, I have been in the architectural+design community for more than 1 year and there are many interesting publications that I found here from all over the world which made me more aware of the beauty of modern architecture and ancient architecture.

And my birthday this time, I did not make any celebrations and all because of a slightly thinning budget.

In the publication of the 17th of my architectural + design publication today, I again want to share the architectural + design process of making the door of a local resident's house in my area.

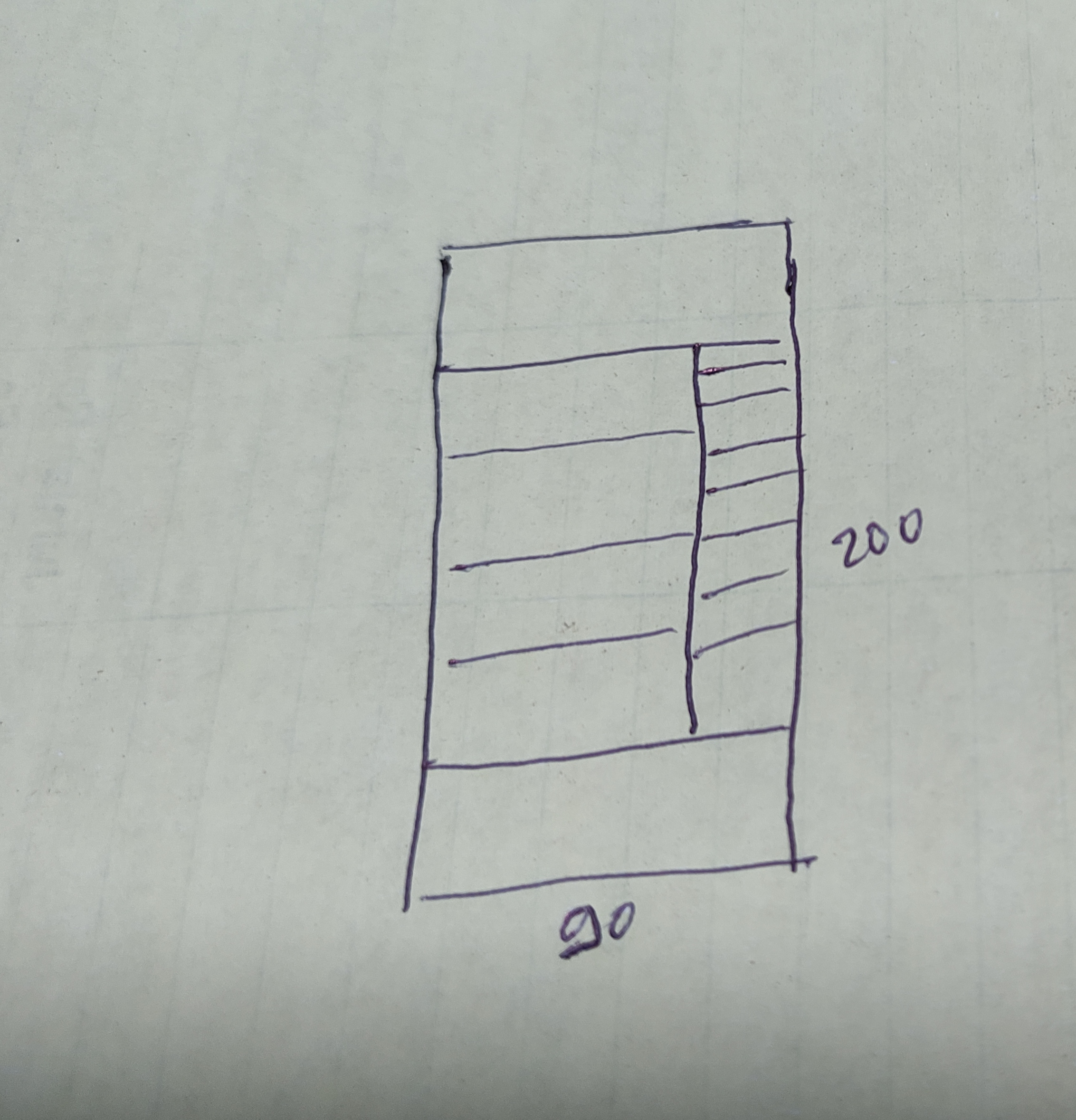

In the construction of a house, the door is a component part of a building and everyone has their own design of choice according to their taste and local residents of rural areas are usually in the construction of the door of the house which is their daily place, the villagers like to imitate and see the door designs of local residents so that they are not wrong in designing doors for their homes and this sometimes becomes one of the habits of the local community in designing a house component, especially in the design of doors and windows and today I will publish architecture + design of house doors made of pine wood and we often refer to door designs this as comb door designs and my customer ordered 1 door unit with a width of 90cm x 200cm and this is the design picture door given by my customer.

From the picture the door design looks very simple and looks very simple and to finish the door of exactly like the design in the picture I need several machines and wood, and the machines that I need to complete the door project include:...

•Meranti wood that has been trimmed ....for the main frame, the left and right of the post and the upper bulkhead, the width of the door which is the main series measuring wide 10.5cm X 3.5 cm thick and the bottom door width of 16cm and the middle door series bulkhead in the form of window material with a size of 3.5 cm x 6 cm is the main binding material for the window series.

•Wood cutting machine to cut all wood materials for door materials.

•Shaving machine to flatten the entire surface of the series connection and make leaf comb carvings.*

•Hand drill(to make holes in the wood when installing the pegs) and sit drill(to make holes in the bulkhead of the top and bottom of the dors).

•Meter and hammer

•Router machine(for making flowers on the inside corners of doors and making leaf holder holes of doors).

•Meter (measuring instrument)and elbow.

•Smoothing machine .

•Panel machine (to make nipple pegs on frame sets) and for door leaf flower panels and.

•Manual iron press to the door series during the process of installing the pegs.

After all the materials are available, now we enter the main process, namely the preparation of a series of left-right door poles and that size of the door 90cm wide x 200 cm high and in the process of making this door we are working on a peg connection system.

and so that there is no mistake in drilling the door series peg holder, we outline the entire holder area and after that I continue the drilling process with a depth of 4 cm and a drill width of 1.5 cm.

After I have finished making the peg holder holes, I now continue the process of preparing the door width assembly material.

And after I calculated the width of the door, the size of the series consists of a length of 77cm X width of 10.5cm = 1 rod, 77cm x 16cm = 1 rod, 77cm x 6cm = 2 rod , bulkhead 47cm long x 6cm wide = 5 rods and bulkhead middle pole 75cm x 6cm = rod.

After all the ingredients are finished I have prepared, now I continue the process of making the nipple of the peg with a size of 1.5 cm x 4 cm using a panel machine and this is how the process of making the peg looks like.

Then after the process of making the pegs is complete now I continue the process of unifying the entire series of frames so that the design of the main series of doors is formed.

And after finishing I put the whole circuit together and I continued the process of trimming to tidy up the entire circuit bulkhead connection and after all the process was finished I worked on the door it would look like this.

.jpg)

The next process, namely giving flowers on the surface in a series of front and rear door bulkheads so that the door looks more beautiful and on the comb leaf holder (a column that has a small width and length) I don't give flowers to the wooden partition because that is where the door comb sits.

and after I finished, I did the process of giving flowers to the door series and the door leaf holder using the router machine, the door would look like this.

And for the next process is giving the leaf on the door and the leaf is made of pine wood according to consumer demand and has a different color between the series and the door leaf, after I cut and smoothed the door leaf, I continued the panel process, namely giving flowers to the entire wood surface after the door leaf manufacturing process was complete, this is what that main door leaf looks like.

And now the process of making the main door sheet sheet I have finished working on and next is the process of making the door comb leaf and the size of the door comb leaf which has a small width and length is 14cm wide and 80cm long.

Maybe you are asking what is the comb that I mean in architectural design of the door of the house?

In general, in architectural design, comb furniture is divided into two models and the process is very different.

A translucent comb, which is a horizontal arrangement of wood with an angled system and a distance of 1cm X 1 cm to be the entry and exit point for free air, and

The comb is not translucent , this is one of the combs that has become an attractive design on the door leaf and is in great demand by the local community,this comb also forms a mereng and is not translucent and has a very neat arrangement and looks so beautiful.

And for this time I will complete an architectural project + comb leaf door design and to complete a comb leaf made of wood with a non-translucent board comb, here I use a shaving machine, to make the door leaf board comb, on a shaving machine

I gave the mall a slightly wrinkled surface and closed 1/2 the razor blade, this is what the mall looks like after I stick it on the shaving table.

And for the sheet of board on which I will form the surface of the comb, I first made nails for the retaining of the door leaf on the main assembly of the door and after the process of making the comb leaf nails is complete, the board sheet will look like this.

After the process is complete, now I continue the process of making the comb on the board using a shaving machine that I have equipped with a mall and I have to shape the shape of the comb on the front back of the board and this is how the process of making that comb looks like.

Then after the process of making the base of the comb is complete, I continue the process of smoothing the corners of the comb by rubbing the surface using sand paper.

And after the refining process is complete, this is how that non-translucent comb sheet looks like.

Then, after the process of making all the leaf doors is complete, now I continue the process of installing the leaves on the main series of doors and the process goes like this.

And then after the installation process of the door leaf was completed, I continued the process of pressing and installing the wooden key lock and to make the peg holder, after I pressed it then I drilled each bulkhead connection of the basic circuit using an electric drill and this is how the image description of the process looks like.

Then after the process was complete, I continued the process of making dumplings made of a mixture of glue and sawdust to cover the small gaps in the wood joints and this is how the process looks like.

And now the comb door is finished and I have to wait for 2 hours until the glue is completely dry, then I continue the process of smoothing the entire wood surface until it is completely smooth and architectural + design finishing finished I working on the comb door made of wood and this is what the picture of the door looks like after I finished working on it.

All of these pictures I take when i was working on that doors and all images were taken using a smartphone camera, if you want to enjoy my previous architectural design works, please visit the post link below.

All of these pictures when i was working on that window and jalousie project ,all images were taken using a smartphone camera, if you want to enjoy my previous architectural design works, please visit the post link below.

1.Architectural design- simple cafe bar table

2.Architectural design - Wooden tray with natural wood color combination/utilization of wood waste

3.Architectural design - Flower vases / utilization of wood waste.

4.Architectural design-Simple architectural design of my baby crib basket.

5.Architectural design-Table simple the combination of natural wood colors and classic table tops

6.Architectural design- Shophouse frame jalousie

7.simple-minimalist-mini-wall-shelf-architectural-design-to-decorate-your-home-room

8.architectural-design-of-the-ventilation-jalousie - part 1

9.architectural-design-of-windows-house -part 1

10.interior-design-architecture-simple-makeup-mirror-frame.

11.architectural-design-simple-minimalist-wooden-window -part 2

12.architectural-design-window-designs-that-are-in-great-demand-by-local-residents

13.architectural-design-of-a-mini-table-and-a-simple-photo-frame

14.architecturaldesign-of-glass-windows-and-jalousies - house

15.Architecture + door design of local people's houses.

16.Furniture design architecture || Making multiplex doors for motorcycle workshops.

The rewards earned on this comment will go directly to the person sharing the post on Twitter as long as they are registered with @poshtoken. Sign up at https://hiveposh.com.

Wahh keren banget om @deltasteem terus berkarya dan semoga sukses selalu usahanya Aamiin 😇

Dear @citaamanda. Kindly add/provide the English language translations to your comment for the reading convenience of our international Hive audience. Thank you for your consideration.

Thankyou so much @aplusd will noted for future 🤗

Furniture design are not always easy as it take a long of time couple with a lot of works and efforts on it. You really did a great job here

Greetings☺

and it's true as you said and in this door design project, at the stage of making the comb it is very complicated :)

Thank you for sharing this amazing post on HIVE!

Your content got selected by our fellow curator @priyanarc & you just received a little thank you via an upvote from our non-profit curation initiative!

You will be featured in one of our recurring curation compilations and on our pinterest boards! Both are aiming to offer you a stage to widen your audience within and outside of the DIY scene of hive.

Join the official DIYHub community on HIVE and show us more of your amazing work and feel free to connect with us and other DIYers via our discord server: https://discord.gg/mY5uCfQ !

If you want to support our goal to motivate other DIY/art/music/homesteading/... creators just delegate to us and earn 100% of your curation rewards!

Stay creative & hive on!

Hello @deltasteem. Your project is one of the most unique door designs I've seen! Aside from giving the impression of appearing like window louvers, the entire door serves as an attractive accent design for a house entrance. Impressive! 😊

thank you @storiesoferne and all the door designs that I share are door designs that are often used by local people in my area for generations :)

Congratulations @deltasteem! We're delighted to specially curate your awesome publication and award it RUNNER-UP in Architecture Brew #68. More power!

Thank you for subscribing to Architecture+Design, an OCD incubated community on the Hive Blockchain.

thanks @aplusd and I will continue to be enthusiastic in publishing architectural furniture designs.

Always a wonderful pleasure to have you here dear @deltasteem. Keep up the fantastic posts! 😀