Greetings architecture + furniture design and as usual I am @deltasteem one of the employees of Cv furniture for the local community and in the last few days I have just been working on an architectural design + furniture door package project and in recent years, people are more interested in simple house door designs which of course have very strong durability and in this week I also just finished a two-faced wooden door architecture project .

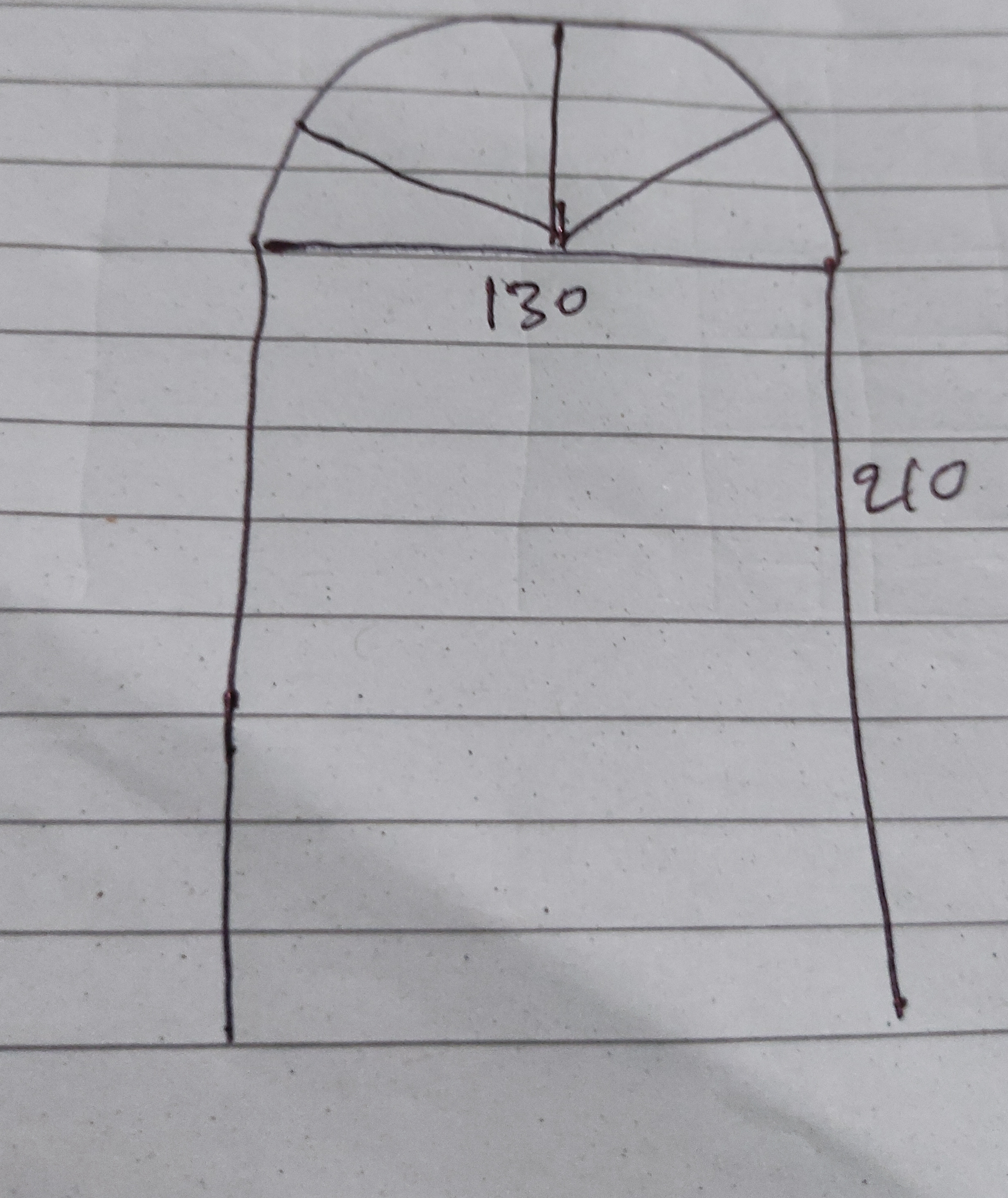

And that door stands in a complete package with the door frame with a frame size of 130 X 210 cm wide and at first my customer brought two different door frame design pictures to find out the price difference for the two frames and for the first picture design like this one.

For that design of the frame, the manufacturing process is quite complicated and after I calculated the budget that had to be prepared for the door frame design package of around $302, finally my customer decided to replace the design with the usual door frame package design which is often used by the local community at a fairly cheap price with a picture of a door and frame design like this.

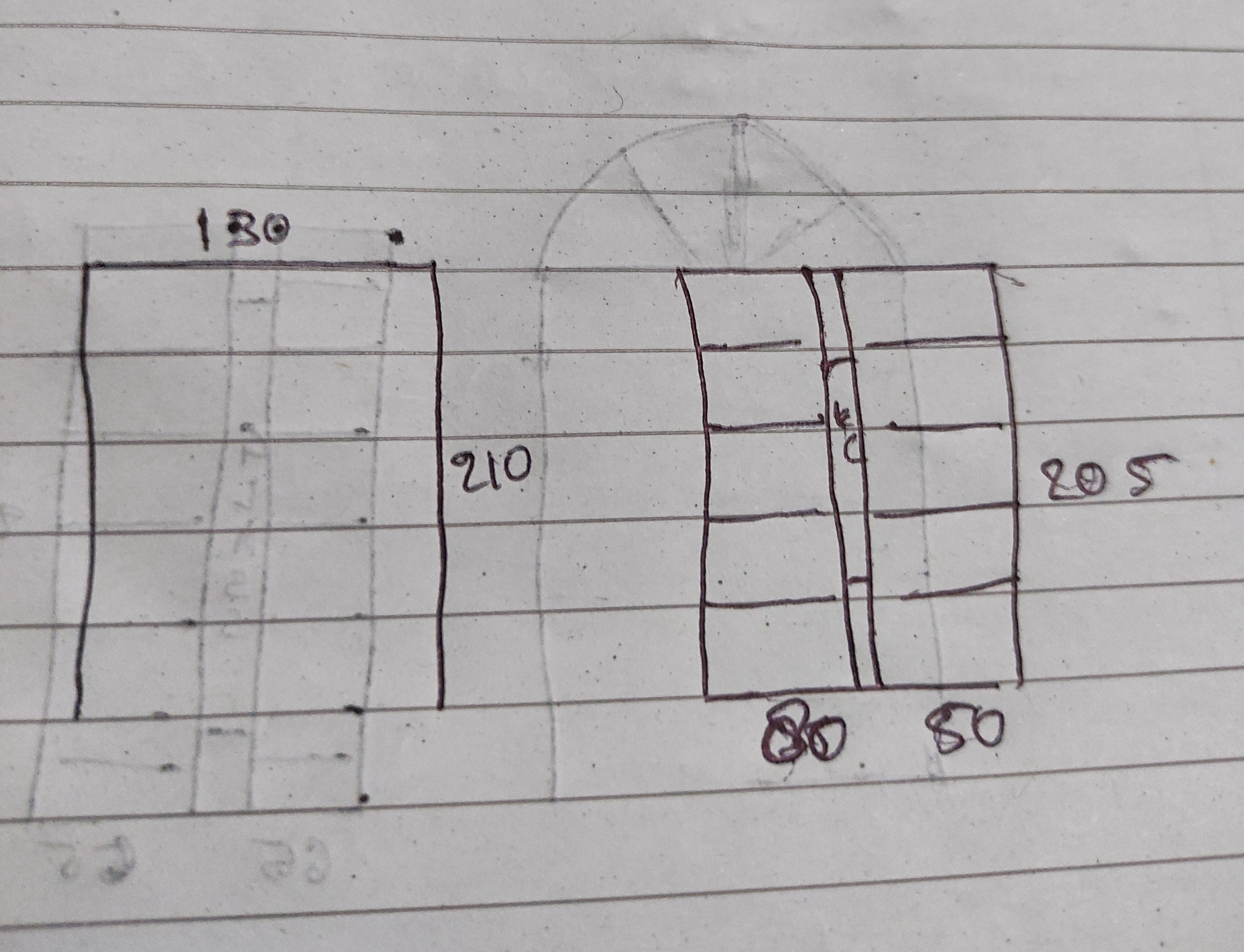

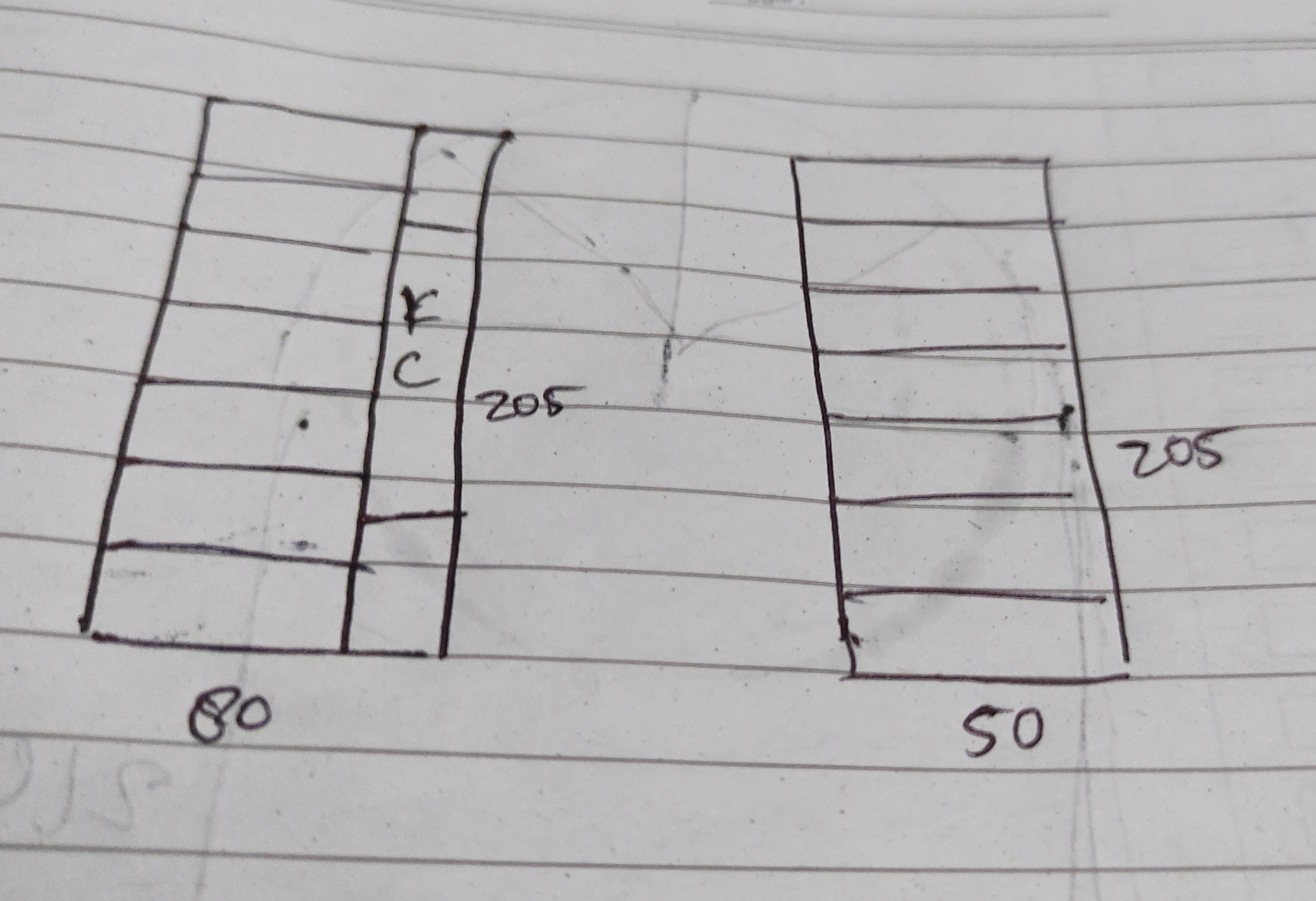

And for this design package my customer had to prepare a budget of $205 with a semi meranti door and a frame made of meranti wood, with a frame measuring 130cm wide X 210 cm high and with two open doors measuring 80cm wide and 50 cm X 205 cm and for the door design, my customer asked me to put a small mirror on the 80cm wide door sheet with a double image like this of that pair of doors.

To complete that project package, I first worked on making the door frame first and of course to complete the project I needed some of the main materials for the frame that is,,

Meranti wood beams that have been trimmed using a main shaving machine up to a width of 12.5cm and a thickness of 5.5cm that have been equipped with sponges or door mount rails on the frame.

And the machine tools I need to complete that project, are the machine tools I usually use every day ie.

• Wood cutting machine.

• Flower engraving machine on the corner of a wooden surface.

• Meter.

• Elbow roller .

• Wood chisel .

• Hammer and

• 4 inch nails.

After all the materials were available, I continued the manufacturing process by preparing two left and right poles of the frame with a height of 210cm.

After that I continued the process of making the upper frame of the frame and continued the carving process for the left and right pole holder of the frame.

Then after the carving process is complete, now I continue the process of unifying the entire series using 4-inch nails and continue the process of taking the angled holder, giving the frame retaining wood and also I continue the process of shaving for smoothing the corners of the wood connection surfaces and smoothing the front and back of the frame.

And then after the surface fireplace process is complete, now I continue the process of trimming the frame nails and continue the flower router process on the back surface of the frame so that the frame looks neater and nicer.

And now the meranti frame with a width of 130cm X height of 210 cm I finished working on and this is what the picture of the frame looks like after I finished working on it.

Now I continue the process of making two-faced doors for that frame.

And the door for frames have different sizes and we can see the design in this picture,by ordering semi meranti wood, according to my customer's order.

To complete that project for a pair of doors, here I need the main ingredients, namely.

•Meranti wood that has been trimmed with a size of 10.5cm X 3.5cm thick.

•Meranti wood that has been trimmed with a width of 16 cm and a thickness of 3.5 cm for the bee screen at the bottom of the door and

•Meranti wood material measuring 6 cm wide and 3.5 cm thick as a door bone bulkhead.

And for the machine tools that I need, the same as the machines that I used in the process of making that door frame.

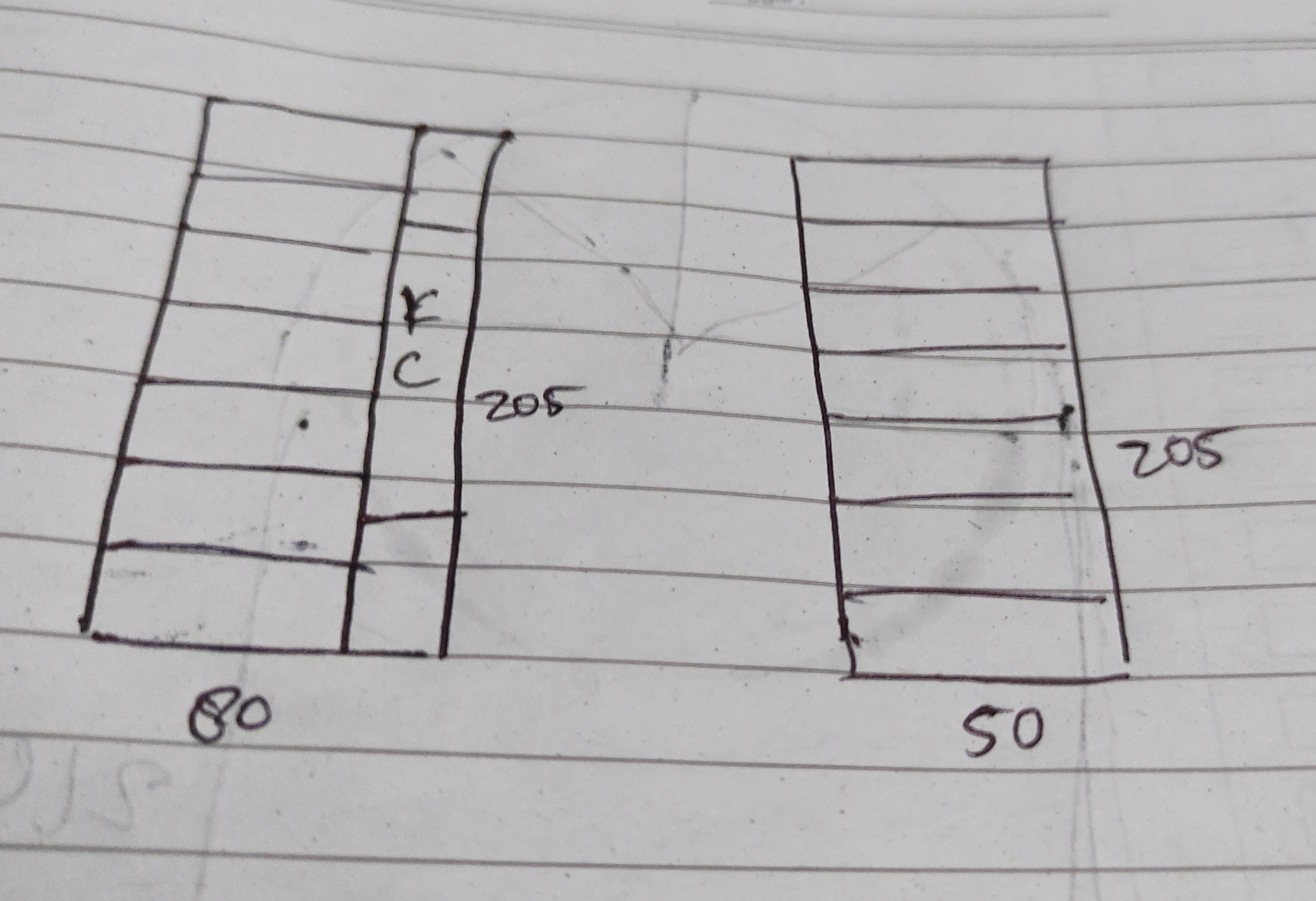

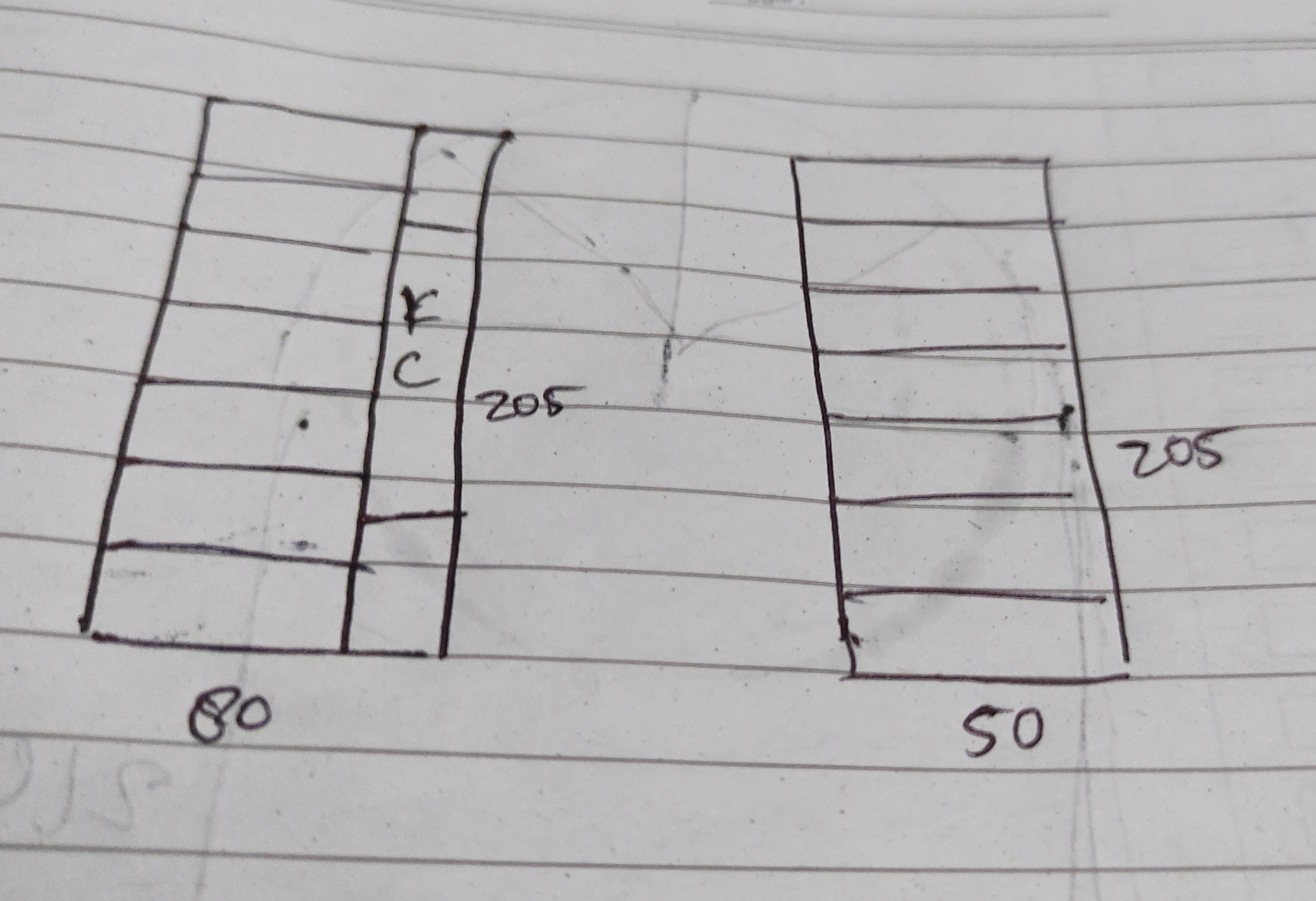

And to finish making the door, I first prepared 4 meranti logs that had been trimmed with a width of 10.5cm and a thickness of 3.5cm and a length of 210cm and in the door design drawing it is written the length of the door is 205cm and the two doors have different designs with different door widths and the same height.

Then I proceeded to prepare the 4 left-right door post frames and continued to outline the door width bulkhead mounting area for the process of drilling the post nipple mounts.

After the process of measuring and lining the nipple hole holder, the width of the door,I continued the drilling process on the 4 pillars of that main door frame and I did the drilling with a sitting wood drilling machine with a drill depth of 4cm with a drill bit width of 1.5cm and the size of the drill in accordance with the width of the door connection bulkhead.

For the bottom bulkhead of the door, the width of the door, the length of the nipple, the peg is 16cm, the top is 10.5cm and the middle bulkhead is 6cm.

Then, after the drilling is complete, now I continue the process of cutting the door width divider and for the wide bulkhead the two doors have different lengths.

For a door measuring 80cm wide x 205 cm high, the length of the bulkhead that I have to prepare is:

•1 the upper bulkhead of the door with a width of 10.5 cm and a length of 67 cm which consists of a left and right 4 cm peg nipple.

•1. the upper bulkhead of the door with a width of 16 cm and a length of 67 cm which consists of a left and right 4 cm peg nipple.

• 7 the upper bulkhead of the door with a width of 6 cm and a length of 52 cm which consists of a left and right 4 cm peg nipple.

• 1 the upper bulkhead of the door with a width of 6 cm and a length of 186,5cm which consists of a left and right 4 cm peg nipple and

• 2 the upper bulkhead of the door with a width of 6 cm and a length of 17cm which consists of a left and right 4 cm peg nipple.

For a door measuring 50cm wide x 205 cm high, the length of the bulkhead that I have to prepare is:

•1 the upper bulkhead of the door with a width of 10,5 cm and a length of 37 cm which consists of a left and right 4 cm peg nipple.

•1 the upper bulkhead of the door with a width of 16cm and a length of 37 cm which consists of a left and right 4 cm peg nipple .

• 7the upper bulkhead of the door with a width of 6 cm and a length of 37 cm which consists of a left and right 4 cm peg nipple and

After all the materials were finished and I cut them using an electric wood mino cutting machine, then I continued the process of making pegs on that two door bulkheads simultaneously using a panel machine.

Then after the process of making the nipple and peg is complete, the wooden partitions will look like this with the length of the nipple of the peg 4cm and thickness of 1.5cm.

Then after all the materials from the drilling preparation stage to making the peg nipple I finished working on, now I continue the process of unifying the entire series and first I finish the process of unifying the door series measuring 50cm x 205 cm and this is how the process and layout of the circuit looks like.

And after the sides of all the door width connection bulkheads are installed, the circuit will look like this.

Next is the process of unifying a series of doors measuring 80cm x 205 cm.

and for this series door the design is different from its partner door , where in the middle bulkhead of the door, we provide a little transparent white glass according to customer requests and the design of the glass bulkhead arrangement is also slightly different so as to produce a distinctive door design that looks so beautiful when the door is installed simultaneously on the house building and this is the arrangement of the circuit for that door.

And after completing the process of unifying all that circuit bulkheads from the two-faced door, the two doors will look like this.

And now I continue the process of trimming to smooth the entire surface of the wood joints.

For the shaving process, I did it simultaneously using a hand shaving machine and after that process is complete the door circuit will look like this.

.jpg)

Then I continued the process of giving flowers on the top and bottom surfaces of the door chain using a hand router machine.

.jpg)

After that I continued the process of scratching the door retainer which I also did using a router machine.

Then after the process of shaving and giving flowers on the surface of the series until the scraping of the door leaf holder is complete,the desain frame two-faced door measuring 80cm x 205 cm and 40cm x 205 cm will look like this.

And now the stage of preparing the leaves for that two doors.

For the door, I gave a white pine plank with a leaf width of 19cm for both doors and consisting of 1cm left and right retaining nails.

For the first process, I prepared a door leaf measuring 80cm x 205 cm wide with a total of 8 leaves with a leaf length of 46cm x 19 cm consisting of 1 cm nails around it.

and also I prepared a door leaf measuring 50cm x 205 cm wide with a total of 8 leaves with a leaf length of 31cm x 19 cm consisting of 1 cm nails around it.

After the process of preparing the door leaf is complete, now I continue the process of leaf panels/giving flowers on the front and back leaf surfaces.

And after the penel process is complete that door leaves will look like this.

.jpg)

Next is the process of installing that door leaf on both doors.

.jpg)

To install the door leaf boards with a planting system, of course I have to re-disassemble the entire series of door bulkheads and reassemble them at the same time and that process goes like this.

And for the installation of the 80cm x 205 cm door leaf I had to disassemble 1/5 of the frame and prepare the glass on the main bulkhead and the installation process went like this.

Next, the process of installing the glass on the door in the front bulkhead box area.

And after the process of installing the leaves and on the two door sheets, the door will look like this.

Next, the process of pressing / locking the angle of the door width connection.

For locking all corners of the door connection, here after pressing, I used wooden dowels and drilled holes first using a hand drill.

And after the locking of the connection of the pegs was complete, then I dumplings some of the bulkhead of the connection using glue and a mixture of sawdust and after that, I waited a few hours for the glue to dry completely and continued the sanding process until the surface of the front and back doors was smooth and tidy and after the sanding is done.

This is what the architectural design of the two-faced door furniture looks like, complete with frames made from meranti wood frames and semi meranti wooden doors.

And the two doors will be installed together and this is roughly this result of that two-faced door after being installed on the house building complete with the frame.

Greetings #hive architecture + furniture design.

All of these pictures when i was working on that window and jalousie project ,all images were taken using a smartphone camera, if you want to enjoy my previous architectural design works, please visit the post link below.

1.Architectural design- simple cafe bar table

2.Architectural design - Wooden tray with natural wood color combination/utilization of wood waste

3.Architectural design - Flower vases / utilization of wood waste.

4.Architectural design-Simple architectural design of my baby crib basket.

5.Architectural design-Table simple the combination of natural wood colors and classic table tops

6.Architectural design- Shophouse frame jalousie

7.simple-minimalist-mini-wall-shelf-architectural-design-to-decorate-your-home-room

8.architectural-design-of-the-ventilation-jalousie - part 1

9.architectural-design-of-windows-house -part 1

10.interior-design-architecture-simple-makeup-mirror-frame.

11.architectural-design-simple-minimalist-wooden-window -part 2

12.architectural-design-window-designs-that-are-in-great-demand-by-local-residents

13.architectural-design-of-a-mini-table-and-a-simple-photo-frame

14.architecturaldesign-of-glass-windows-and-jalousies - house

15.Architecture + door design of local people's houses.

16.Furniture design architecture || Making multiplex doors for motorcycle workshops.

17.Architecture+furniture design || Simple comb design house door.

18.Architecture + furniture design || A pair of doors home belonging to local residents.

You are very skilled and good luck always

thanks for your good wishes and may you always be healthy there.

The rewards earned on this comment will go directly to the people(@deltasteem) sharing the post on Twitter as long as they are registered with @poshtoken. Sign up at https://hiveposh.com.

Such a thorough explanation with detailed pictures! Love it!

thanks @kingdariusthe3rd and furniture is part of my daily work.

Another job well done my friend, keep it up.

hehe thanks friend :)

You're welcome (^_^)

hello to @jlufer thank you and as usual I do it according to the orders of the local community :)

thank you @soulsdetour and I think for a while it became one of the traditional door designs of local people today and for the price the door in my city is quite varied it all depends on the material followed by different prices ☺