Welcome to September all hiveans friends, hopefully this will be the start of a month full of blessings for all of us and I am @deltasteem from aceh, indonesian province who works as an architectural furniture employee at one of the furniture cv in aceh.

And in the middle of last August we just moved the CV building, the process of demolition and construction of a new CV building lasted for 2 weeks and now our new cv has started to be active again as usual.

I, as a furnisher in the CV, after the inauguration of the job field, I immediately continued my work activities as usual by continuing the process of making house doors which were left over from old orders belonging to the local community.

For the door design of the community around me, generally the surrounding community often takes the door design from the surrounding community's house as well as the door design that I just finished a few days with a door design like this.

.jpg)

this is a picture of the door design provided by my customer which is equipped with the width X height of the order door and the door order has two different width sizes with the same door design, namely;

2 door units measuring 90 cm wide X 190 cm and

2 doors with a width of 90cm X 190 cm.

My customer before ordering the door once asked me about the price via a WA message by sending a picture of that door.

The door in the picture is not my CV production door and this is one of the door designs that has a pattern arrangement which of course has a longer durability,my customer ordered the door with the basic material of meranti wood frame, which is one type of wood that is well known among the public and for that price of 5 units of the door my customer has to prepare a fee of $340.

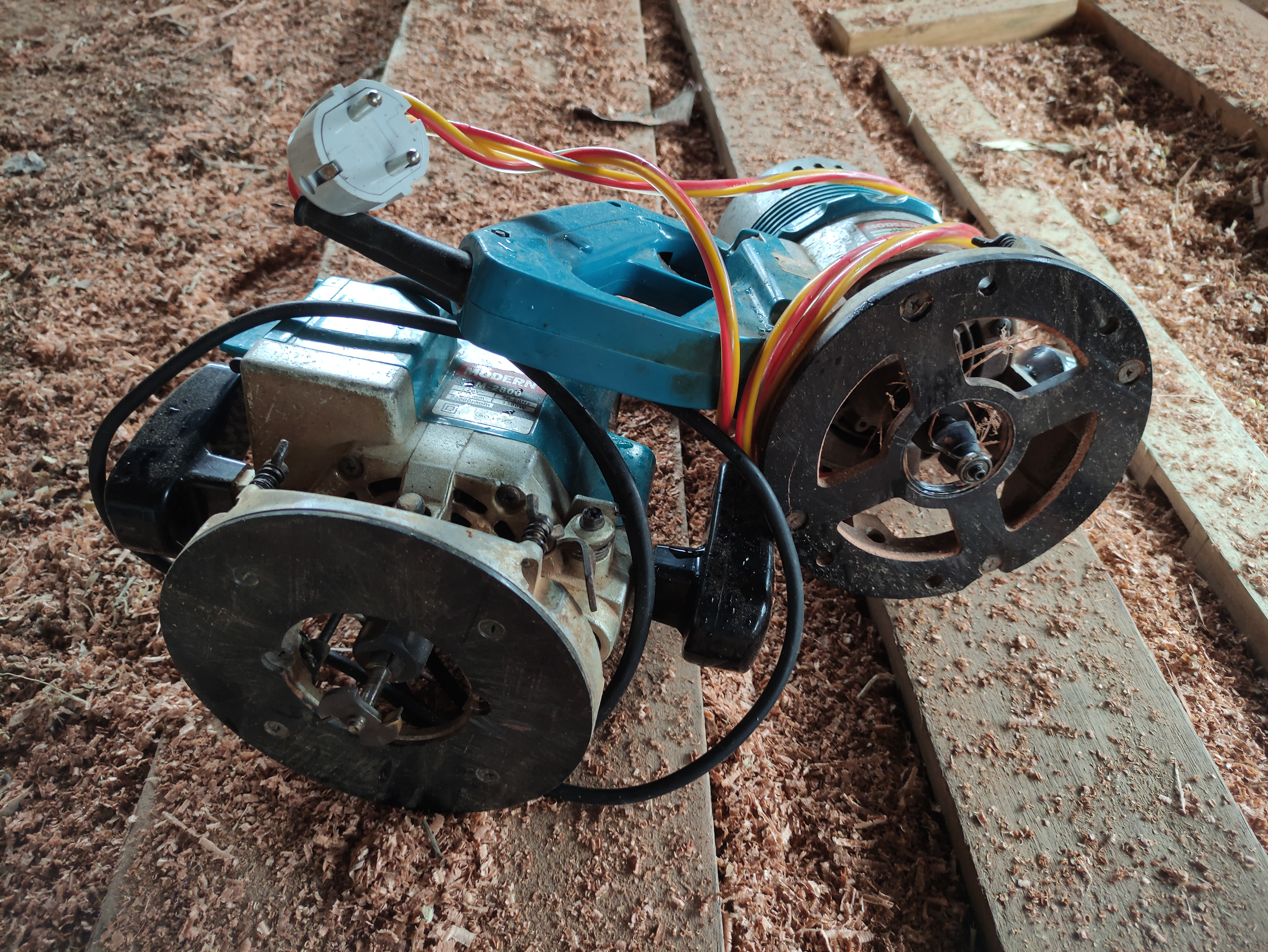

And today I am again sharing an architectural design project for the process of making the door, which is made of meranti wood frame and pine wood door leaf sheet and before we enter the manufacturing process,we need to provide some work equipment such as;

•Wood cutting machine to cut all wood materials .

*•Shaving machine to flatten the entire surface of the wood. **

•Hand drill(to make holes in the wood when installing the pegs) and sit drill(to make holes in the bulkhead of the top and bottom of the dors).

• hammer

•Router machine.

•Meter (measuring instrument)and elbow.

•Smoothing machine .

•Panel machine (to make nipple pegs on frame sets) and for door leaf flower panels and.

•Manual iron press to the door series during the process of installing the pegs.

For the size of the material we need in the process of making that door, the size of the wood that we often use is as follows, starting from the size of the main circuit to the size of the wood of the arrangement of the bones.

•Meranti wood that has been trimmed ....for the main frame, the left and right of the post and the upper bulkhead, the width of the door which is the main series measuring wide 10.5cm X 3.5 cm thick and

•Bulkhead connection The width of the bottom door is 16cm wide and 3.5cm thick.

•The middle door series bulkhead in the form of window material with a size of 3.5 cm x 6 cm .

•And a wide board for the door leaf.

In the first stage of the work, I myself completed the material for the left and right pillars of the door by outlining the length of the door and the outline of the bulkhead holder for the connection of the width of the door and for the five doors have the same length, so we can do the process of outlining the height of the door and the layout of the door divider at the same time.

Of the five door units, I had to prepare 10 pole bulkheads with a length of 190cm and after the process of outlining the length of the door was complete, then we continued the process of drilling the door width bulkhead mounts on all the main pillars.

And the number of drilling points on the main pole of the left and right doors is certainly different and everything is determined by the door design to put a design circuit divider and for the door that I'm working on this time on the main pole left of the door there are 8 drilling points with different lengths of drilling points.

For the drilling point on the right main post, it only contains 4 points with a drill bit width of 1.5cm and a drilling depth of 4cm y and the length of the drilling point is much different for the main bulkhead above the door, the drilling length is 8.5cm and for the bottom door width bulkhead the drilling point is long. 14cm and for bulkhead connections in doors, the average drilling point length is 4cm with an average drill bit depth of 4cm.

After the drilling process for the door width connection bulkhead holder on the main post was completed, I then completed the second stage, namely the preparation of the door chain bones.

For the reinforcement of the door frame, we use wood that is the same size as the main door chain with a width of 10.5 cm X 3.5 cm thick and for the bottom bulkhead we use wood with a width of 16 cm X 3.5 cm thickness and for reinforcement Our doors use wood measuring 6cm wide X 3.5cm thick.

The total wood bulkhead for the series of door widths that I have to prepare for the series of door designs with different widths and lengths for the door is as follows.

2 units doors for wood partitions for doors measuring 200cm high X 90cm wide.

•2 wooden partitions measuring 10.5cm wide x 3.5cm thick and 77cm long.

•2 wooden partitions measuring 16cm wide x 3.5cm thick and 77cm long.

Wood for the bulkhead pattern in the door.

•4 wooden partitions measuring 6cm wide x 3.5cm thick and 45cm long and

Wooden partitions for doors measuring 200cm high X 80cm wide.

•3 wooden partitions measuring 10.5cm wide x 3.5cm thick and 67cm long.

•3 wooden partitions measuring 16cm wide x 3.5cm thick and 67cm long.

Wood for the bulkhead pattern in the door.

•4 wooden partitions measuring 6cm wide x 3.5cm thick and 40cm long.

And for the center post of the door to form a design like the one in my picture, I used a wood size of 6cm X width 3.5 cm and the length of the bulkhead for all the doors is the same as 161 cm long with 5 partitions.

After the process of preparing the reinforcement circuit is complete, for the next stage, namely the process of making the nipple of the peg at the end of the door reinforcement that we have prepared previously with a length of 4cm of the nipple of the peg according to the depth of drilling on the main pole of the frame.

And to prepare the process of making the nipples of the pegs on the wooden partitions of the door pattern, I used a panel machine.

We have to do it step by step carefully.

The dowel must be in the middle with a thickness of 1.5 cm according to the size of the drill bit in the main series.

And after the process of making the nipple pegs is complete, I continue the process of drilling in some bulkheads to place the bulkheads on the inner surface of the door.

And for the next stage, which is to unite all the pieces of wood on the main door frame and the process is like this.

And after the assembly process is complete, this is the result of the main circuit pattern of that door.

The next stage is the front and back surface fireplaces of the door series using a drawstring machine.

The thickness of the door chain before the trimming process was around 3.5 cm and I had to trim the surface of the door connection until it became 3.2 / 3.3 cm thick so that the door matched the clean size of the door frame series sponing on the building house.

And after the process of setting the surface of the series is complete, then the process of giving flowers and the process of scraping the door holder.

In the process stage of giving flowers and giving the leaf nipple peg holes on the inner surface of the door, here we use a router machine.

The two router machines that we use are of different sizes with different rotational speeds and also consist of two different bits, namely the big machine we use the scraper blade for the door holder and the small machine we use the flower stamping machine on the surface of the door arrangement.

For the first process, namely giving flowers on the surface in a series of doors and here we use a small router machine.

And after the process of giving flowers to the door series is complete, then the process of scraping the door leaf peg holder and here we use a large router machine with eye of scraping holes.

Now the stage of preparing the door circuit is complete and the door design looks very simple.

The next stage is the process of preparing the door leaf boards for all these doors.

For door boards, we usually use boards with a width of 22cm X 2cm thickness and the type of board we use is pine board.

And the length and width of the boards that I have to use for the doors are of course different, namely.

For 2 doors measuring 200cm long X 90cm wide.

•4 boards 22cm wide X 72cm long consisting of 2cm nails around them.

•10 boards 22cm wide X 48cm long consisting of 2cm nails all around and

•2 boards 20cm wide X 163.5cm long consisting of 2cm nails all around.

For 2 doors measuring 200cm long X 90cm wide.

•6 boards 22cm wide X 62cm long consisting of 2cm nails around them.

•15 boards 22cm wide X 42cm long consisting of 2cm nails all around and

•3 boards 15cm wide X 163.5cm long consisting of 2cm nails all around.

And after the process of preparing the door leaf board material is complete, then the panel process of all the doors is done using a panel machine.

And after the process of giving flowers to that door leaf board, all ends of the board surface will look like this.

The next stage is the process of installing the board on a series of door frames.

When installing the door leaf on the circuit set, of course, we have to disassemble the entire surface of the connection and rearrange it simultaneously and the installation process goes like this.

And the appearance of the door after the installation stage of the board leaves is complete.

The next stage is the pressing and locking of the corner connection of the door circuit.

For the process of locking the corners of our circuit, we use a wooden key system by drilling each corner of the connection for the peg holder.

After the process of pressing and locking the door joint pegs is complete at each corner of the joint, we also apply a little adhesive glue to make the door really strong.

And now we enter the finishing stage.

For the finishing stage of the door sheet, we smooth the surrounding with an sanding machine repeatedly until the door surface is completely smooth.

and now the design of a wooden door with a height of 200cm X width of 90cm as many as 2 units and 3 units of a door measuring 200cm high X 80cm wide I finished working on within 3 working days.

All of these pictures when i was working on that window and jalousie project ,all images were taken using a smartphone camera, if you want to enjoy my previous architectural design works, please visit the post link below.

1.Architectural design- simple cafe bar table

2.Architectural design - Wooden tray with natural wood color combination/utilization of wood waste

3.Architectural design - Flower vases / utilization of wood waste.

4.Architectural design-Simple architectural design of my baby crib basket.

5.Architectural design-Table simple the combination of natural wood colors and classic table tops

6.Architectural design- Shophouse frame jalousie

7.simple-minimalist-mini-wall-shelf-architectural-design-to-decorate-your-home-room

8.architectural-design-of-the-ventilation-jalousie - part 1

9.architectural-design-of-windows-house -part 1

10.interior-design-architecture-simple-makeup-mirror-frame.

11.architectural-design-simple-minimalist-wooden-window -part 2

12.architectural-design-window-designs-that-are-in-great-demand-by-local-residents

13.architectural-design-of-a-mini-table-and-a-simple-photo-frame

14.architecturaldesign-of-glass-windows-and-jalousies - house

15.Architecture + door design of local people's houses.

16.Furniture design architecture || Making multiplex doors for motorcycle workshops.

17.Architecture+furniture design || Simple comb design house door.

18.Architecture + furniture design || A pair of doors home belonging to local residents.

20.Architecture + Design || Double-faced house door part ll.

21.Architecture + design || Making window for villagers' houses.

22.Architecture+furniture design || Two-faced house door part III

23.Architecture+furniture design || Multiplex door

24.Architecture + Design || Work on minimalist house doors local residents.

The rewards earned on this comment will go directly to the people( @deltasteem ) sharing the post on Twitter as long as they are registered with @poshtoken. Sign up at https://hiveposh.com.

Congratulations @deltasteem! You have completed the following achievement on the Hive blockchain and have been rewarded with new badge(s):

Your next payout target is 8000 HP.

The unit is Hive Power equivalent because post and comment rewards can be split into HP and HBD

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPTo support your work, I also upvoted your post!

Check out the last post from @hivebuzz:

Support the HiveBuzz project. Vote for our proposal!

Your content has been voted as a part of Encouragement program. Keep up the good work!

Use Ecency daily to boost your growth on platform!

Support Ecency

Vote for new Proposal

Delegate HP and earn more

Good job once again my friend, that door made me remember one of my plans for our house, replacing an old door.

hehe thanks frinds so that the process is easier you just make it simple.;)

You're welcome, my friend.

the door design looks elegant even though it is minimalist, meranti wood makes a minimalist design look beautiful @deltasteem

thanks @umirais :)